Boiling-resistant UV (Ultraviolet) curing jet-ink for non-absorbent substrate and preparation method of jet-ink

A non-absorbent base material and inkjet ink technology, which is applied in ink, applications, household appliances, etc., can solve the problems of inconvenient process and complicated operation process, and achieve the effect of enhanced water resistance, simple construction process and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

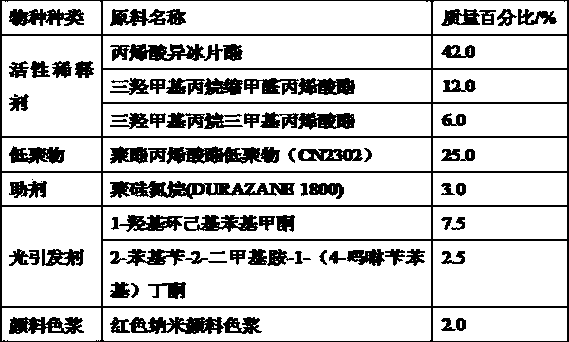

[0033] The present embodiment prepares the raw material of red UV photocurable ink-jet ink and the proportioning ratio as shown in Table 1:

[0034] Table 1 Raw materials and proportions for preparing red UV photocurable inkjet ink

[0035]

[0036] According to the formula and dosage in Table 1, first mix isobornyl acrylate, trimethylolpropane formal acrylate, trimethylolpropane trimethacrylate, polyester acrylate oligomer, and polysilazane evenly , add red nano pigment paste, 1-hydroxycyclohexyl phenyl ketone and 2-phenylbenzyl-2-dimethylamine-1-(4-morpholine benzylphenyl) butanone, and stir under a high-speed mixer After 0.5h, it is uniformly dispersed by a homogenizer, and finally filtered through a 0.45 micron membrane to obtain a red UV light-curable inkjet ink.

[0037] The red UV light-curable inkjet ink prepared in Example 1 has a viscosity of 9cp (25°C), is uniformly dispersed, and has a particle size D90 of about 329nm. The adhesion fastness to ordinary glass re...

Embodiment 2

[0040] The present embodiment prepares the raw material of blue UV photocurable ink-jet ink and the proportioning ratio as shown in Table 2:

[0041] Table 2 Raw materials and proportions for preparing blue UV photocurable inkjet ink

[0042]

[0043]According to the formula and dosage in Table 2, first mix isooctyl acrylate, 1,6-hexanediol diacrylate, polyester acrylate oligomer, and polysilazane evenly, then add blue nano pigment paste, 2 -Hydroxy-2-methyl-1-phenylacetone, 2,4,6-trimethylbenzoyldiphenylphosphine oxide and 2-ethylhexyl 4-dimethylaminobenzoate in a high speed mixer After stirring for 0.5 h, the mixture was uniformly dispersed by a homogenizer, and finally filtered through a 0.45-micron membrane to obtain a blue UV light-curable inkjet ink.

[0044] The blue UV light-curable inkjet ink prepared in Example 2 has a viscosity of 10cp (25°C), is uniformly dispersed, and has a particle size D90 of about 352nm. The adhesion fastness to glazed ceramics reaches 100...

Embodiment 3

[0047] The present embodiment prepares the raw material of yellow UV photocurable ink-jet ink and the proportioning ratio as shown in Table 3:

[0048] Table 3 Raw materials and proportions for preparing yellow UV photocurable inkjet ink

[0049]

[0050] According to the formula and dosage in Table 3, first mix octyl acrylate, tetrahydrofuran acrylate, dipropylene glycol diacrylate, propoxylated trimethylolpropane triacrylate, polyester acrylate oligomer, and polysilazane Evenly, add yellow nano-pigment paste, isopropylthioxanthone and 4-dimethylamino-ethyl benzoate, stir for 0.5h under a high-speed mixer, then disperse evenly through a homogenizer, and finally use a 0.45 micron Membrane filtration, prepared yellow UV photocurable inkjet ink.

[0051] The yellow UV light-curable inkjet ink prepared in Example 3 has a viscosity of 8cp (25°C), is uniformly dispersed, and has a particle size of about 330nm. The adhesion fastness to silicon crystal glass reaches 100%, the har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com