Non-curling flexible composite material

A composite material, flexible technology, applied in the field of textile materials, to achieve the effect of high ink absorption, excellent non-curling performance, and high adhesion fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

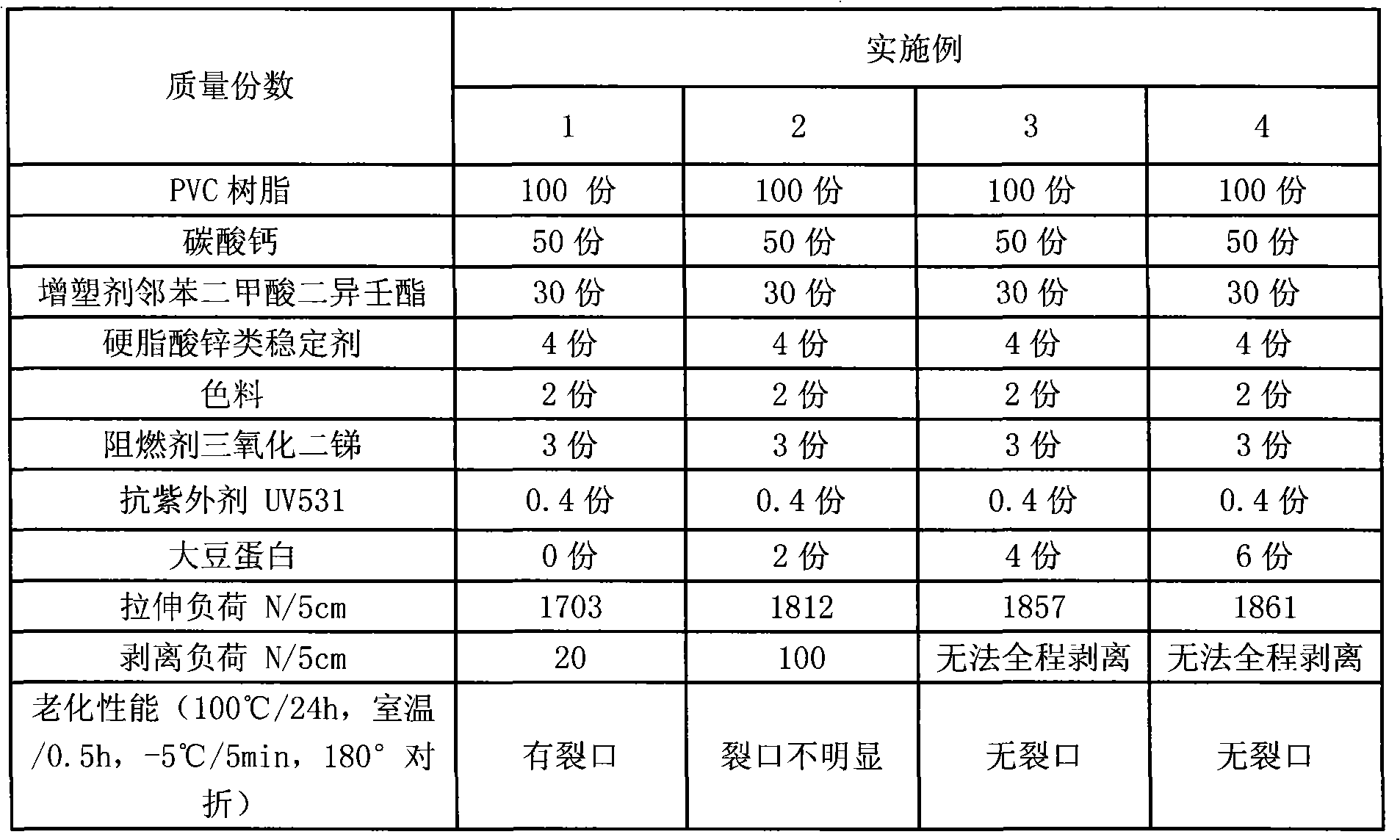

Embodiment 1~4

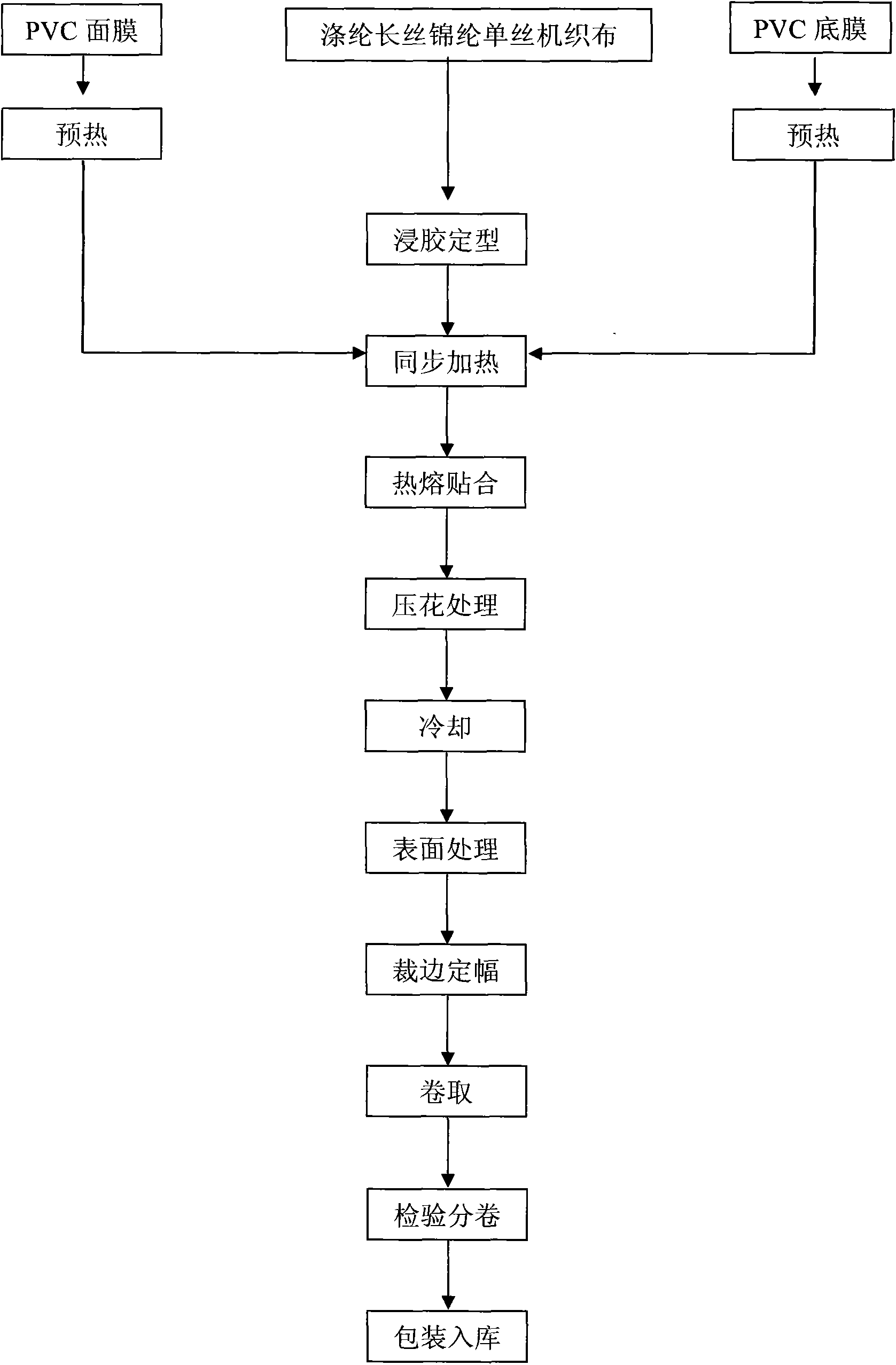

[0029] refer to figure 1 , a non-curling flexible composite material, prepared by the following method:

[0030] (1) High-strength polyester yarn is used as warp yarn, nylon monofilament is used as weft yarn, and woven fabric is made by Sulzer projectile loom plain weaving process as the skeleton material;

[0031] (2) After the skeleton material in step (1) is dipped and preformed, the double-sided PVC film is hot-melt bonded, and then subjected to rapid cooling and surface treatment to obtain a flexible composite material without curling.

[0032] The specification of the high-strength polyester filament is 500d, and the specification of the nylon monofilament is Φ0.25mm.

[0033] The PVC film is produced by the following method: the PVC ingredients are cooled and stirred at a high speed, then planetary extruded to achieve full plasticization in the early stage, and then plasticized again by two-roller refining and then four-roller calendering process to make PVC film.

[00...

Embodiment 5~8

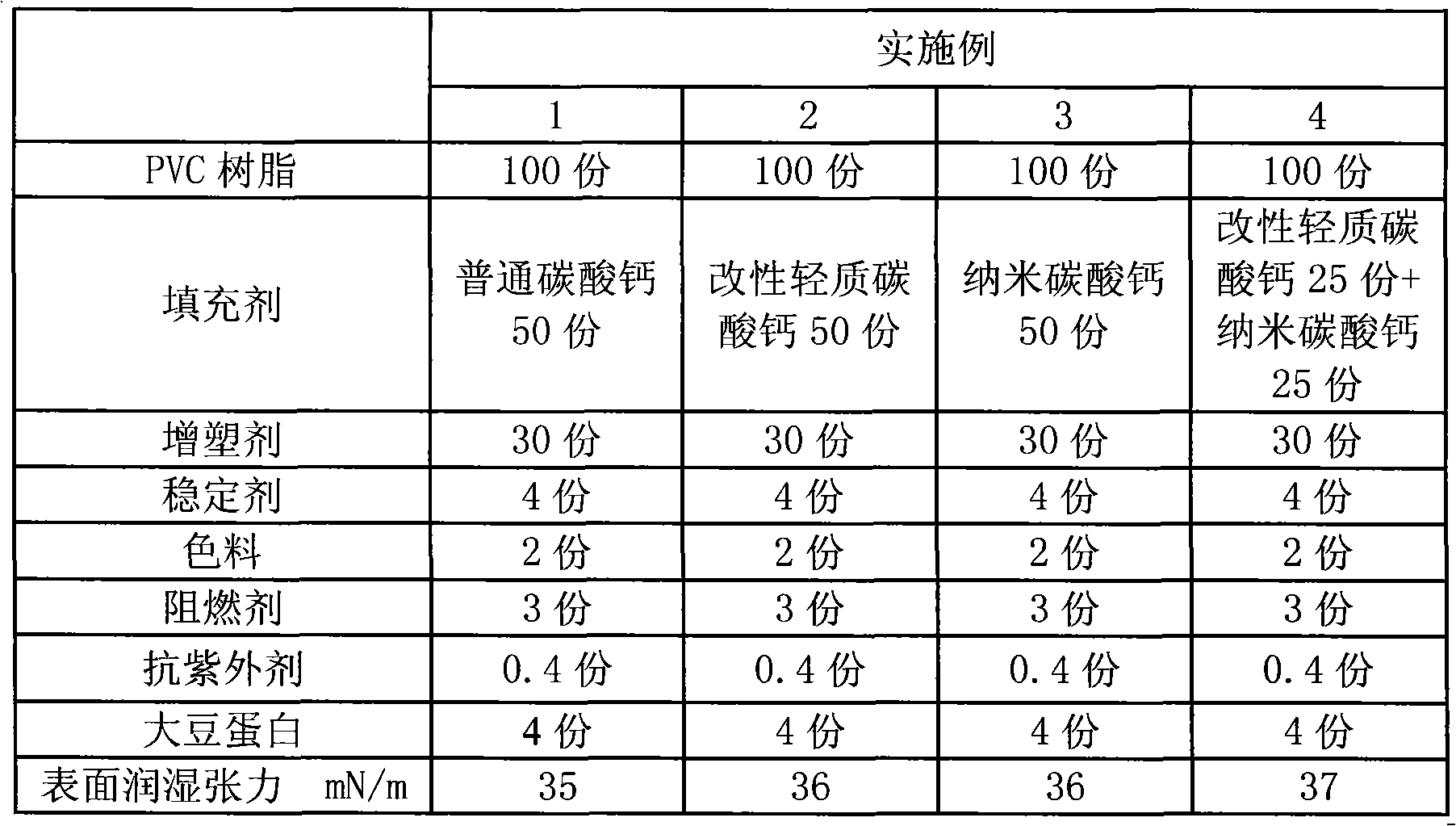

[0042] Change the composition of PVC batching, other preparation technology is the same as embodiment 1. The properties of PVC ingredients and the prepared flexible composite material are shown in Table 2:

[0043] Table 2

[0044]

[0045] The results show that adding the mixture of modified light calcium carbonate and nano-calcium carbonate as a filler, the surface wetting tension of the obtained flexible composite material is the largest, that is, the ink absorption is the best, and the strength is also improved. This is because the modified calcium carbonate can be fully integrated with the organic system, and has good dispersion and compatibility. And because the nano-calcium carbonate is filled in the organic polymer, the interface between the high-modulus calcium carbonate and the low-modulus organic polymer can undergo appropriate stress transfer, making the interface plastic and preventing the interface between the powder and the substrate. Cracks occur due to pe...

Embodiment 9

[0047] The flexible composite material prepared in Example 4 of the present invention is compared with the conventional flexible composite material, and the results are shown in Table 3 below:

[0048] table 3

[0049] Conventional Flexible Composite Materials

[0050] The results show that compared with the conventional flexible composite material, the flexible composite material of the present invention has the advantages of good ink absorption, no curling, high strength, good aging resistance and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| preheating temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com