UV-LED ink-jet printing character ink and preparation method thereof

A UV-LED, inkjet printing technology, used in inks, printed circuit parts, household appliances, etc., can solve problems such as reducing adhesion, high temperature resistance, etc., to improve high temperature resistance, high temperature resistance, and excellent anti-yellowing performance. , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following examples are to further illustrate the present invention, but not to limit the scope of the present invention.

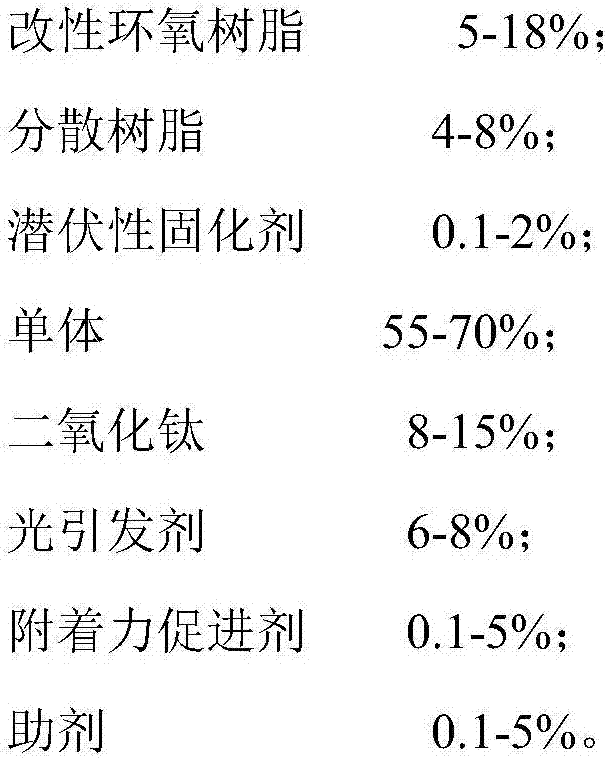

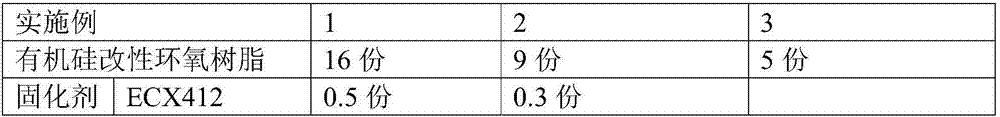

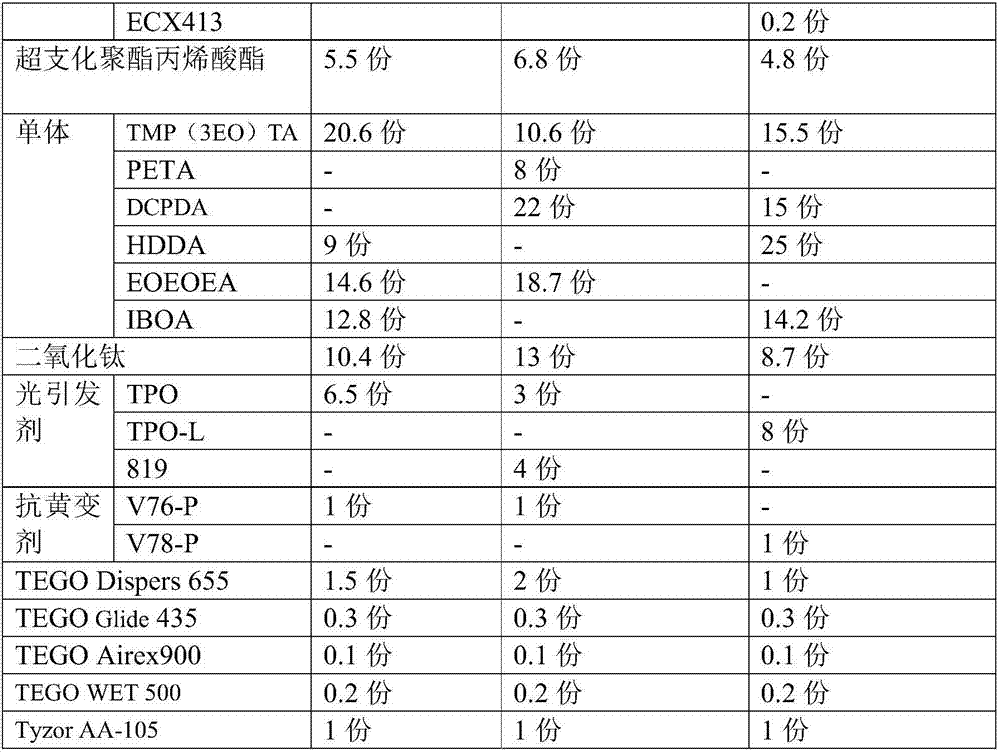

[0041] The raw material components and parts by mass of Examples 1-3 are shown in Table 1.

[0042] Raw material components and parts by mass of Table 1 Embodiment 1-3

[0043]

[0044]

[0045] The preparation method of above-mentioned UV-LED inkjet printing character ink, comprises the following steps:

[0046] (1) Mix the dispersing resin, 10-30% monomer, dispersant, and titanium dioxide, grind it with a grinder until the pigment particle size D50 is less than 300nm, filter to obtain a white nano-color paste, and set aside;

[0047] (2) Dissolving the photoinitiator in the remaining monomers, mix well, and set aside;

[0048] (3) Mix modified epoxy resin, latent curing agent, monomer dissolved with photoinitiator, white nano-color paste, adhesion promoter, auxiliary agent, stir evenly, and then filter through a 1 micron filter membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com