Mildewproof preservative film and preparation method thereof

A fresh-keeping film and anti-mildew technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve problems such as unfriendly to the human body and the environment, food dehydration, etc., to improve the preservation effect and prevent mildew Change, good moisture constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

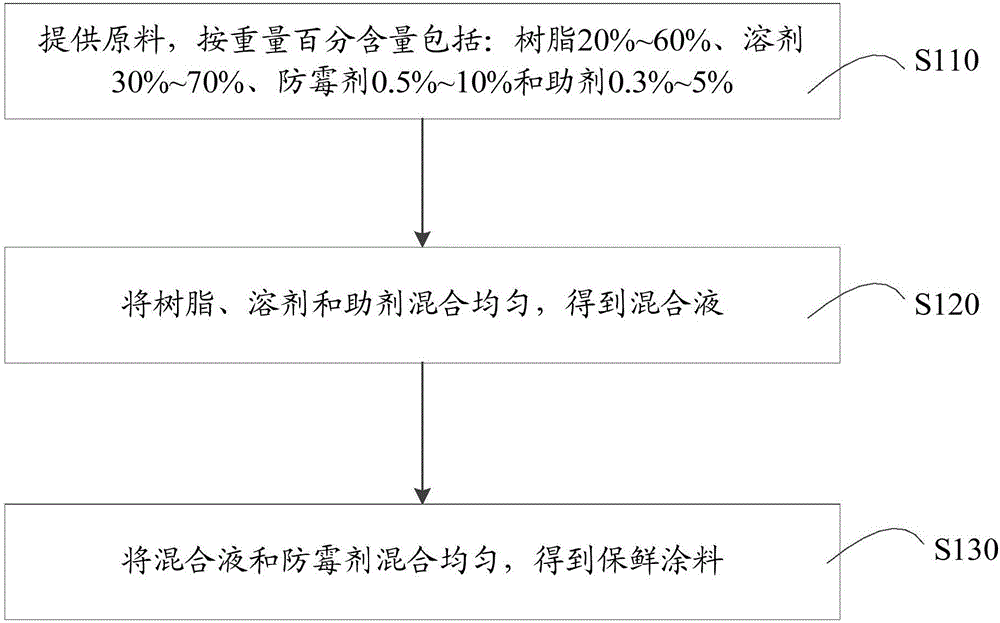

[0039] refer to figure 2 , the preparation method of the above-mentioned mildew-proof and fresh-keeping paint of the present invention comprises the following steps.

[0040] Step S110 : providing raw materials, including by weight: 20%-60% of resin, 30%-70% of solvent, 0.5%-10% of antifungal agent and 0.3%-5% of auxiliary agent.

[0041] Step S120: Mix the resin, the solvent and the auxiliary agent uniformly to obtain a mixed solution.

[0042] Specifically, the temperature at which the resin, the solvent and the auxiliary agent are mixed in step S120 is 30-65°C.

[0043] Specifically, step S120 includes the following steps: dissolving the resin in the solvent, stirring at a rotational speed of 100-300 r / min, and heating to 30-65°C; adding an auxiliary agent, and continuing at a rotational speed of 200-400 r / min Stir for 30-60 min to obtain a mixed solution. The temperature and stirring intensity are controlled in this way to promote uniform mixing of the mixed solution. ...

Embodiment 1

[0059] The raw materials are provided, including 60% of polyurethane resin, 30% of water, 5% of gingerol and 4% of Tween by weight.

[0060] Dissolve the polyurethane resin in water, stir and heat to 50° C. at a rotational speed of 300 rpm; add auxiliary agents and continue stirring for 50 min at a rotational speed of 300 rpm to obtain a mixed solution. The pH of the mixture after the addition of triethylamine was 7.

[0061] The gingerol was added dropwise to the mixture under stirring at a rotating speed of 600 rev / min. After the dropwise addition of the gingerol was completed, the mixture and the gingerol were continued to be stirred and mixed at a rotating speed of 600 rev / min 1. Cool down to obtain anti-mold and fresh-keeping paint.

[0062] Press 10g / m 2 The coating amount of the PET film was coated on the PET film, and then treated at 80°C, 90°C, 120°C, 100°C and 85°C for 1.2s, respectively, to obtain a mildew-proof fresh-keeping film.

Embodiment 2

[0064] The raw materials provided include, by weight, 47% of polyvinyl alcohol 2488 resin, 40% of water, 8% of the total amount of sorbic acid and turmeric, 2% of Tween and 3% of sodium bicarbonate.

[0065] The polyvinyl alcohol 2488 resin was dissolved in water, stirred at a rotating speed of 100 r / min and heated to 65°C; an auxiliary agent was added, and the stirring was continued at a rotating speed of 200 r / min for 30 min to obtain a mixed solution. The pH of the mixture was 8 after the addition of sodium bicarbonate.

[0066] Sorbic acid and turmeric root alcohol are added dropwise to the mixed solution under stirring at a rotating speed of 800 rev / min. After the dropwise addition of sorbic acid and turmeric root alcohol is completed, the mixed solution, sorbic acid and turmeric root alcohol are continued to rotate at a rotating speed of Stir and mix at 500-800 rpm for 2h. Cool down to obtain anti-mold and fresh-keeping paint.

[0067] The anti-mold and fresh-keeping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com