Super-hydrophobic textile and preparation method thereof

A super-hydrophobic, fabric technology, applied in the fields of plant fibers, textiles and papermaking, medical science, etc., can solve the problems of cumbersome preparation process, complex nanoparticle/polymer process, difficult industrial production, etc., and achieve fast preparation process and abundant output. , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, preparation possesses the superhydrophobic fabric of mesh structure

[0031] Dissolve 0.5g of paraffin in 36mL of n-heptane to obtain a solution. In this solution, the mass ratio of paraffin to n-heptane is 1:50. A piece of cotton fabric with a mesh size of 100 mesh is soaked in the solution; keep soaking for 24 hours Take it out and dry it quickly with hot air to get a fabric with super-hydrophobic (blood) properties.

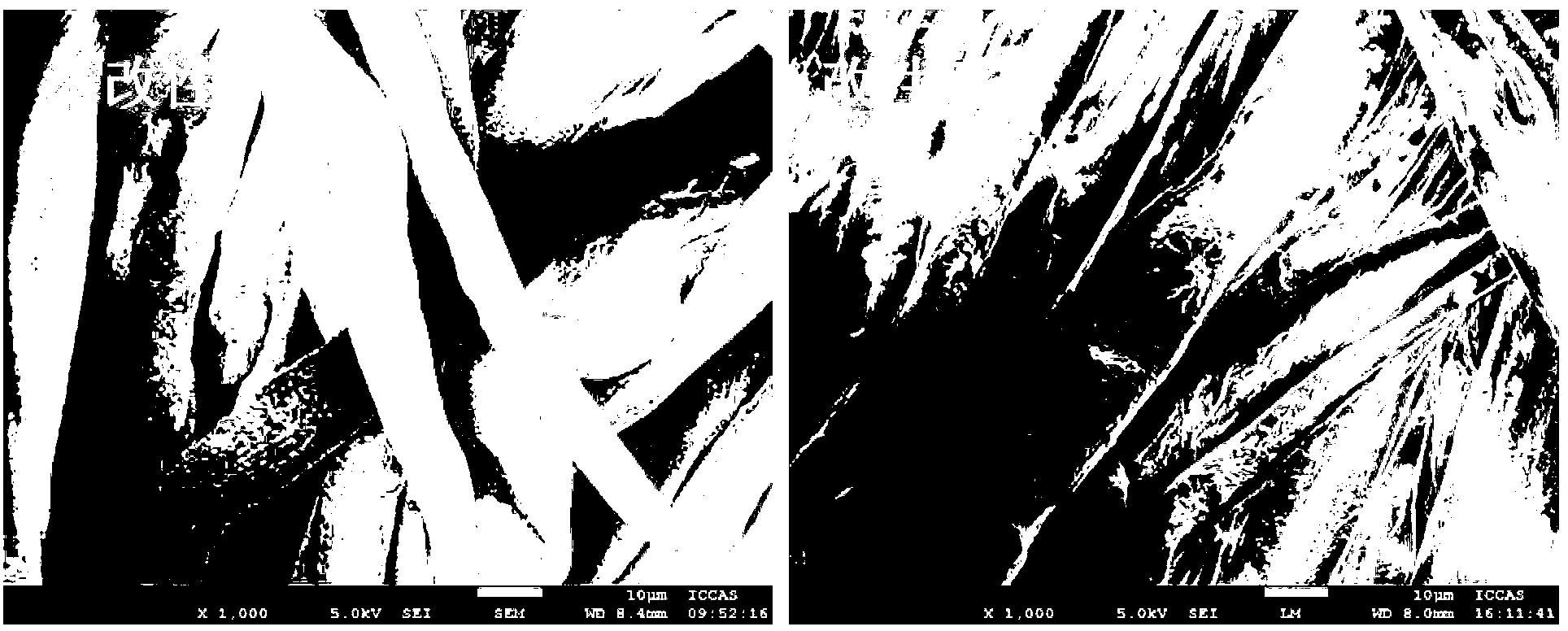

[0032] The scanning electron micrographs of the superhydrophobic fabric prepared in this embodiment and the unmodified raw material fabric used are as follows figure 1 As shown, it can be known from the figure that the surface of the modified fabric fiber is wrapped with wax, which reduces the surface free energy of the fabric. superhydrophobicity.

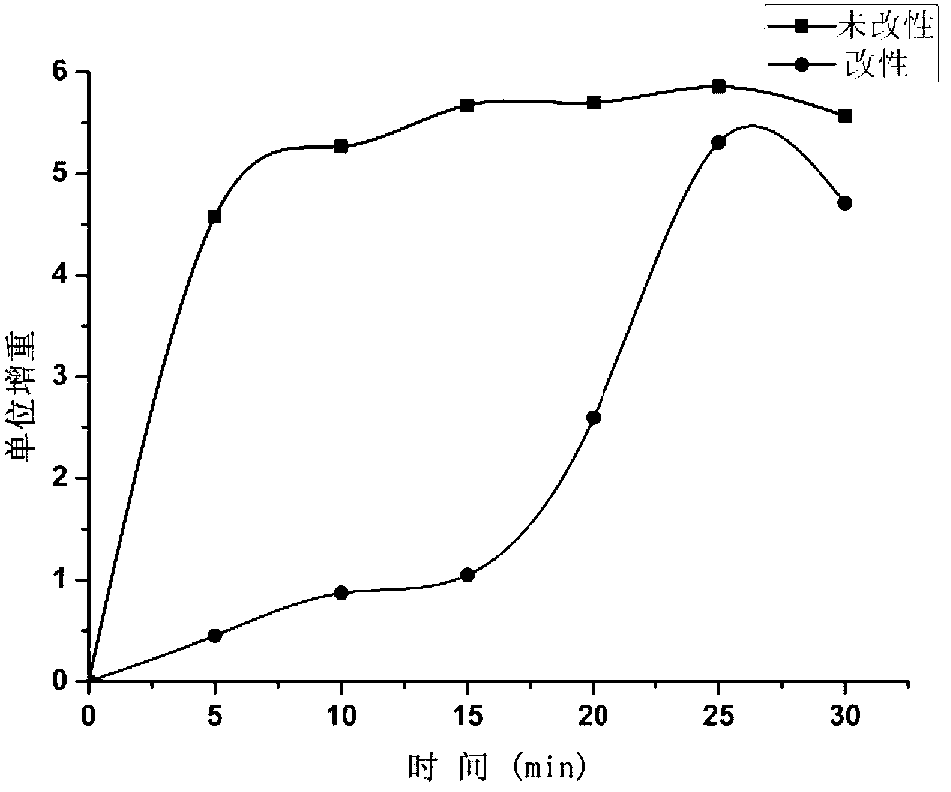

[0033] Determination of the blood adsorption capacity of the superhydrophobic fabric prepared in this example: take the superhydrophobic fabric (cotton fabric), weigh its initial weight, the...

Embodiment 2

[0035] Embodiment 2, preparation possesses the superhydrophobic fabric of mesh structure

[0036] Dissolve 2.5g of paraffin in 35mL of n-hexane to obtain a solution. In this solution, the mass ratio of paraffin to n-hexane is 1:9. Soak a piece of cotton fabric with a mesh size of 200 mesh in the solution, keep it for 10min, and then take it out. Rapid drying with hot air results in fabrics with superhydrophobic (blood) properties.

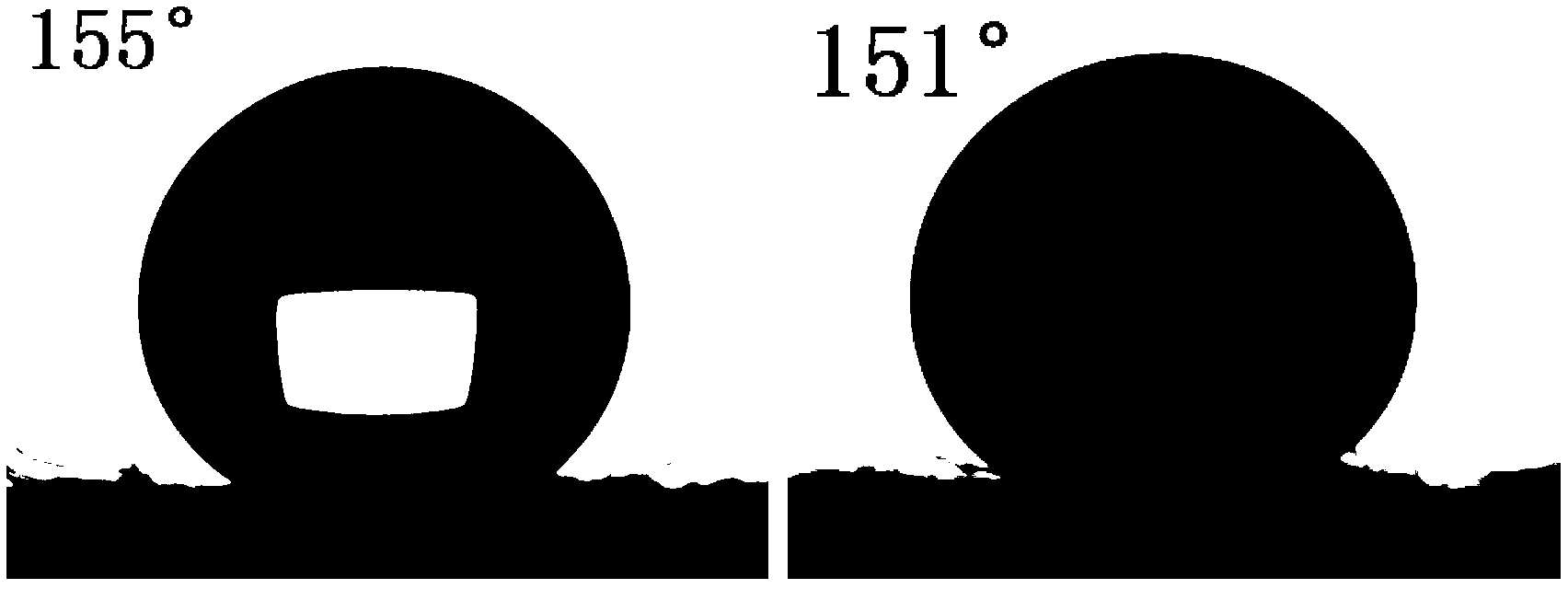

[0037] The static contact angle photos of the superhydrophobic fabric prepared in this embodiment to water and blood are as follows image 3 As shown, among them, the left figure is the static contact angle for water, and the right figure is the static contact angle for blood.

[0038] The photos of blood on the fabric prepared in this embodiment and the surface of unmodified fabric are as follows: Figure 4 shown by image 3 and Figure 4 It can be known that the contact angle of the superhydrophobic modified fabric to water is 155°, and the c...

Embodiment 3

[0040] Embodiment 3, preparation possesses the superhydrophobic fabric of mesh structure

[0041] Dissolve 0.35g of paraffin in 32mL of cyclohexane to obtain a solution. In this solution, the mass ratio of paraffin to cyclohexane is 1:70. Soak a piece of cotton and linen fabric with a mesh size of 50 mesh in the solution and keep it for 1min. Take it out and use natural drying to get a fabric with super-hydrophobic (blood) properties.

[0042] Measure the superhydrophobic fabric prepared in this embodiment to the adsorption capacity of blood, and the measuring method is the same as that in Example 1, and the change curve of the unit weight gain of the fabric in blood with the soaking time is as follows: Figure 6 shown. Depend on Figure 6 It can be seen that compared with the unmodified fabric, the superhydrophobic modified fabric has much less blood adsorption per unit weight within a certain period of time, and has obvious hemophobic ability, which can be applied to preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com