Preparation method of highly hydrophobic edible membrane

An edible film and hydrophobic technology, applied in flexible coverings, packaging, layered products, etc., can solve problems such as difficult absorption or degradation, food impact, poor biocompatibility, etc., and achieve the effect of simple method and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

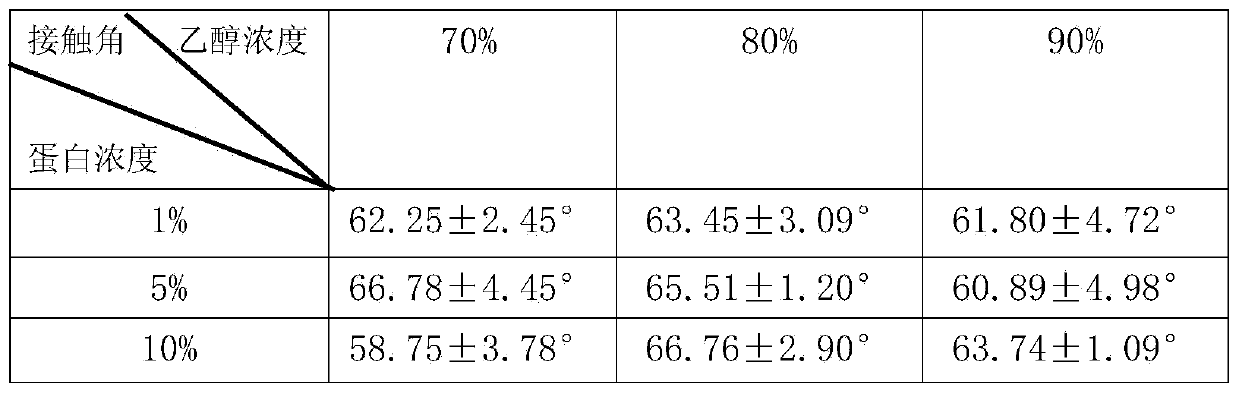

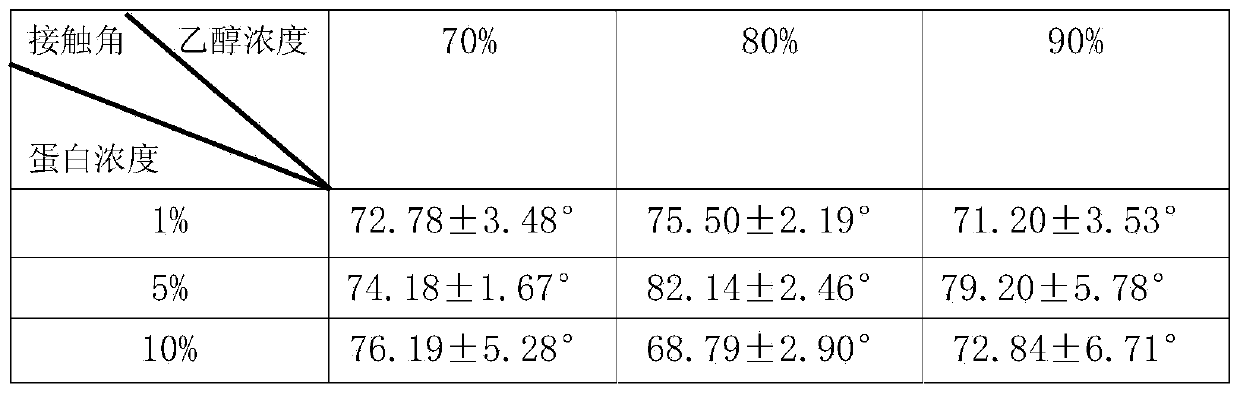

[0051] In the first step, defatted chitosan is prepared into acetic acid aqueous solution, the concentration of acetic acid is 1%, and the concentration of chitosan is 1%. After fully hydrating, it is evenly drip-coated on a glass plate, and placed in a constant temperature and humidity box to dry. Drying is to place the material in a constant temperature and humidity box, the temperature of the constant temperature and humidity box is 25° C., and the relative humidity is 40%.

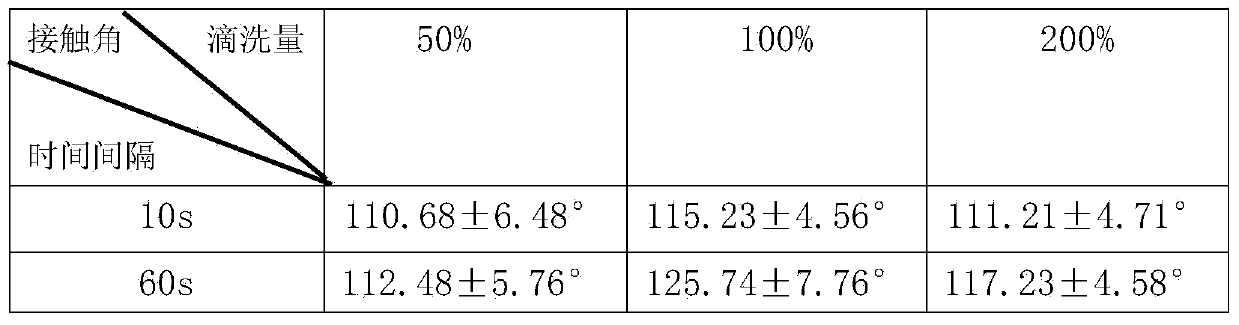

[0052] The second step prepares the ethanol aqueous solution that ethanol mass content is 80%, will be equivalent to the zein protein of ethanol aqueous solution quality 5% to add wherein, after fully dissolving, obtain zein solution, will be relative to the first step chitosan The 100% zein solution of the volume of the solution is evenly drip-coated on the glass plate obtained in the first step, and after 60s, use deionized water equivalent to 200% of the chitosan solution volume in the first step, an...

Embodiment 2

[0058] In the first step, defatted chitosan is prepared into acetic acid aqueous solution, the concentration of acetic acid is 1%, and the concentration of chitosan is 1%. After fully hydrating, it is evenly drip-coated on a glass plate, and placed in a constant temperature and humidity box to dry. Drying is to place the material in a constant temperature and humidity box, the temperature of the constant temperature and humidity box is 25° C., and the relative humidity is 40%.

[0059] The second step prepares 80% ethanol-water solution, adds wherein the zein protein that is equivalent to 5% of solution, after fully dissolving, obtains zein protein solution, will be 100% with respect to the chitosan solution volume of the first step % zein solution is evenly drip-coated on the glass plate obtained in the first step, and after 60s, use deionized water equivalent to 200% of the chitosan solution volume in the first step, the plate is inclined at 45 °, and the water flows from Th...

Embodiment 3

[0066] In the first step, defatted chitosan is prepared into acetic acid aqueous solution, the concentration of acetic acid is 1%, and the concentration of chitosan is 1%. After fully hydrating, it is evenly drip-coated on a glass plate, and placed in a constant temperature and humidity box to dry. Drying is to place the material in a constant temperature and humidity box, the temperature of the constant temperature and humidity box is 25° C., and the relative humidity is 40%.

[0067] The second step is to prepare 90% ethanol-water solution, add zein protein equivalent to 1% of the solution, and after fully dissolving, apply the amount of 100% of the chitosan solution volume in the first step evenly on the On the glass plate obtained in the first step, after 0s, use deionized water equivalent to 200% of the volume of the chitosan solution in the first step, the plate is inclined at 45°, and the water is dripped from the upper part of the plate to the lower part, and the washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com