Cavitation mixer

a cavitation mixer and mixer technology, applied in the direction of flow mixers, mixers, transportation and packaging, etc., can solve the problems of difficult to avoid, device effects only relatively poor mixing of fiber-material suspension components, and the intensity of the cavitation field produced using the device described in u.s. pa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

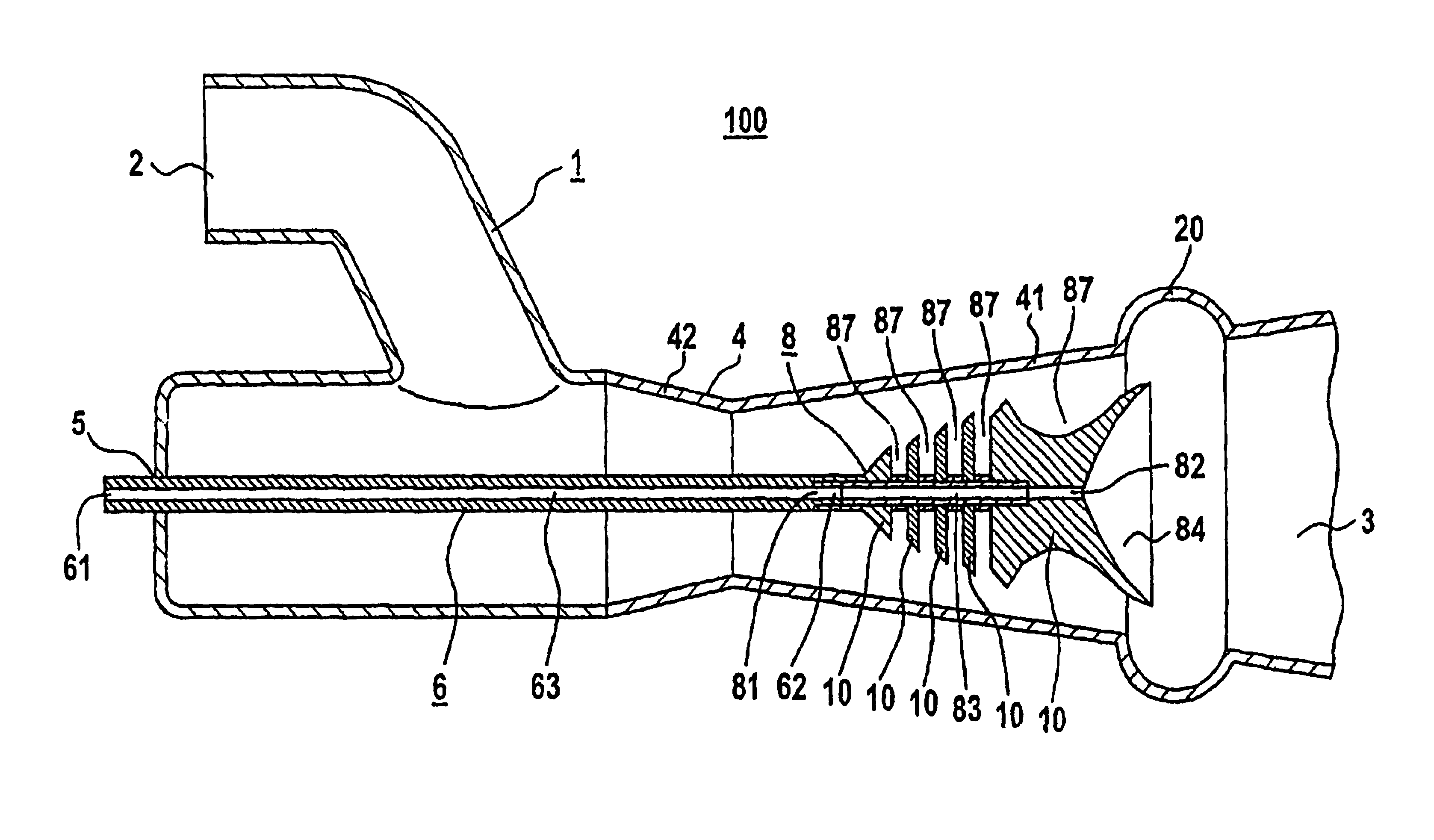

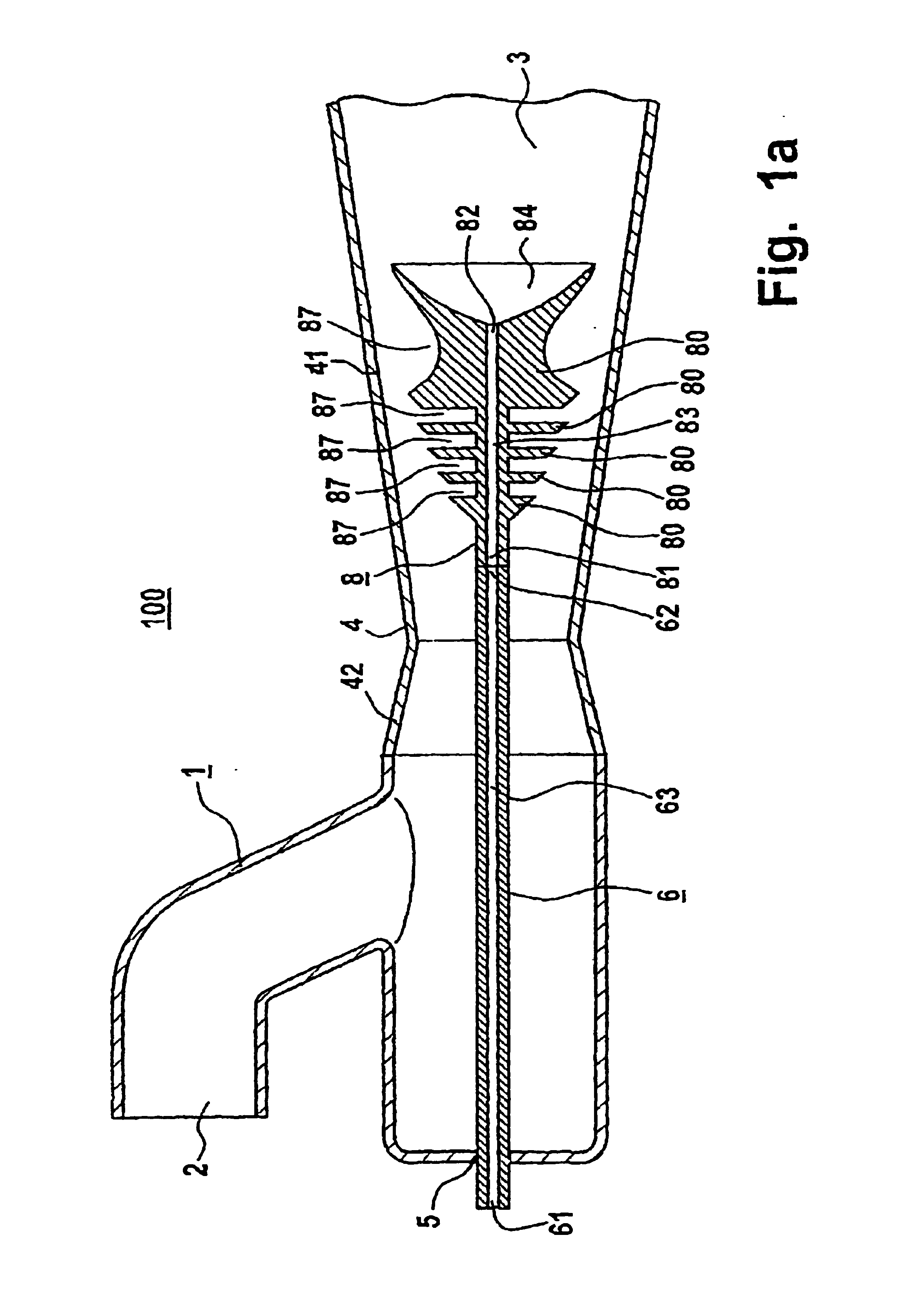

[0063]The housing 1 furthermore comprises a through-flow chamber 4 and a body 8 which is arranged therein by means of a holder 6 and which it is difficult for medium to flow around. In the case of the first embodiment, the holder 6 is designed and arranged in such a way that it projects into the housing 1 through a further opening 5 in the housing, in such a manner that the body 8 which it is difficult for medium to flow around is positioned in the through-flow chamber 4.

[0064]In the embodiment which is diagrammatically depicted in FIG. 1a, the through-flow chamber 4, the body 8 which it is difficult for medium to flow around and the holder 6 each comprise a rotationally symmetrical body, which bodies are arranged in such a way that their axes of symmetry coincide, i.e. are identical to the center axis of the through-flow chamber 4.

[0065]In particular, in FIG. 1a the holder 6 substantially comprises a hollow bar, i.e. has a hollow space 63 which passes all the way through and has an...

second embodiment

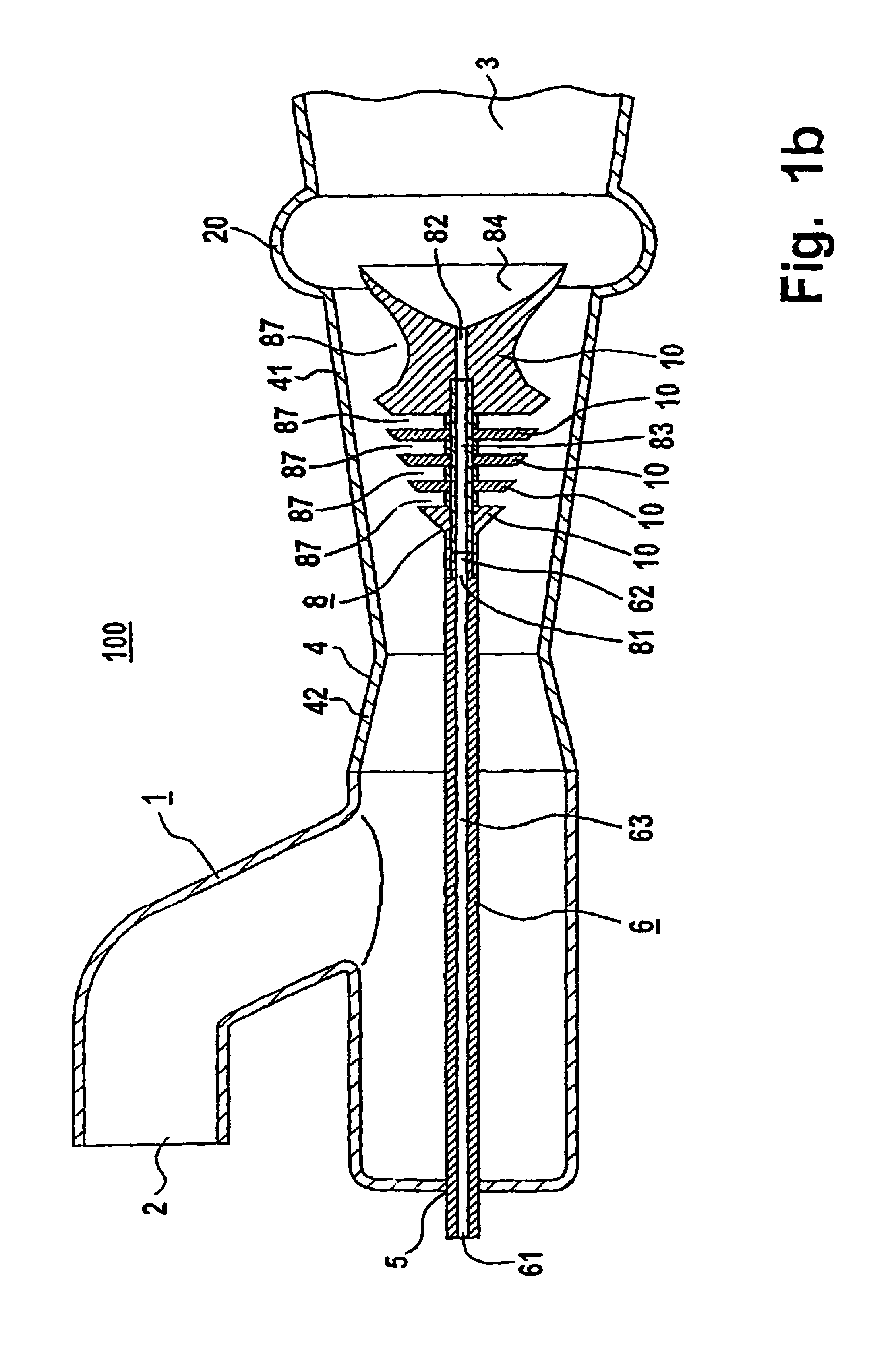

[0074]FIG. 1b shows a diagrammatic cross-sectional view, in the longitudinal direction of a supercavitation mixer 100 in accordance with a second exemplary embodiment of the invention, which represents a modification to the first exemplary embodiment shown in FIG. 1a. In particular, the invention differs from the first by dint of only two modifications.

[0075]The first modification relates to the body 8 which it is difficult for medium to flow around and which in the second embodiment is designed in such a way that each of its subregions 80 which it is difficult for medium to flow around and which is in the form of a truncated cone is designed as a partial body 10. Accordingly, the last two—as seen in the direction of flow—subregions 80, which it is difficult for medium to flow around, of the first embodiment are now designed as a single partial body 10. The spaces 87 through which medium can flow, between the subregions 80 or partial bodies 10 which it is difficult for medium to flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com