Antifouling and wear-resisting textile material and preparation method thereof

A textile material and wear-resistant technology, which is applied in the direction of textiles and papermaking, artificial silk manufacturing, conjugated artificial filament, etc., can solve the problem of unsuitable fluororesin, and achieve cheap raw materials, good wear resistance and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

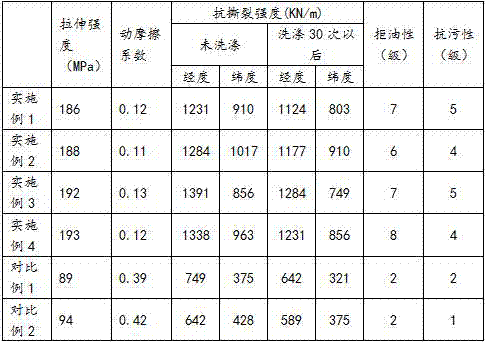

Examples

Embodiment 1

[0024] (1) Weigh 10 parts of acrylonitrile fiber, 12 parts of carboxymethyl cellulose, 2 parts of nanocrystalline cellulose, 10 parts of bamboo charcoal fiber, 11 parts of diglycidyl ether, 3 parts of lauryl alcohol, bis-( Phenyldimethylsiloxane) 1 part of methyl silanol, 4 parts of beta hydroxybutyrate, 1 part of sodium thiosulfate pentahydrate, 8 parts of terephthaloyl chloride, 3 parts of fluorosilane, pyrethrum 1 part of methyl phosphate, 2 parts of butyl peroxide benzoyl acetate, 3 parts of 2,2'-diaminoethylene glycol diphenyl ether, 1 part of zinc ricinoleate, 1 part of barium metaborate, triphosphite 2 parts of phenyl ester, 2 parts of taurate, 1 part of capric acid triglyceride;

[0025] (2) Add acrylonitrile fiber, carboxymethyl cellulose, nano-microcrystalline cellulose, bamboo charcoal fiber, diglycidyl ether, lauryl alcohol, bis-(phenyl dimethyl siloxane) methyl silanol, β-hydroxy Add butyrate and taurate to the reaction kettle, stir and mix well, heat to 230°C, s...

Embodiment 2

[0032] (1) Weigh 13 parts of acrylonitrile fiber, 15 parts of carboxymethyl cellulose, 4 parts of nanocrystalline cellulose, 14 parts of bamboo charcoal fiber, 15 parts of diglycidyl ether, 3 parts of lauryl alcohol, bis-( phenyl dimethyl siloxane) 1 part of methyl silanol, 5 parts of beta hydroxybutyrate, 2 parts of sodium thiosulfate pentahydrate, 10 parts of terephthaloyl chloride, 4 parts of fluorosilane, pyrethrum 2 parts of methyl acid ester, 2 parts of butyl peroxide benzoyl acetate, 4 parts of 2,2'-diaminoethylene glycol diphenyl ether, 1 part of zinc ricinoleate, 1 part of barium metaborate, 5-sulfonate 3 parts of salicylic acid dihydrate, 3 parts of lignosulfonate, 2 parts of iodopropynyl butyl carbamate;

[0033] (2) Add acrylonitrile fiber, carboxymethyl cellulose, nano-microcrystalline cellulose, bamboo charcoal fiber, diglycidyl ether, lauryl alcohol, bis-(phenyl dimethyl siloxane) methyl silanol, β-hydroxy Add butyrate and lignosulfonate to the reaction kettle,...

Embodiment 3

[0040] (1) Weigh 21 parts of acrylonitrile fiber, 20 parts of carboxymethyl cellulose, 8 parts of nanocrystalline cellulose, 17 parts of bamboo charcoal fiber, 23 parts of diglycidyl ether, 4 parts of lauryl alcohol, bis-( Phenyldimethylsiloxane) 2 parts of methyl silanol, 5 parts of beta hydroxybutyrate, 2 parts of sodium thiosulfate pentahydrate, 13 parts of terephthaloyl chloride, 6 parts of fluorosilane, pyrethrum 3 parts of methyl phosphate, 3 parts of butyl peroxide benzoyl acetate, 4 parts of 2,2'-diaminoethylene glycol diphenyl ether, 2 parts of zinc ricinoleate, 2 parts of barium metaborate, three parts of citrate 4 parts of sodium salt dihydrate, 4 parts of aminoguanidine sulfonate, 3 parts of maleate;

[0041](2) Add acrylonitrile fiber, carboxymethyl cellulose, nano-microcrystalline cellulose, bamboo charcoal fiber, diglycidyl ether, lauryl alcohol, bis-(phenyl dimethyl siloxane) methyl silanol, β-hydroxy Add butyrate and aminoguanidine sulfonate to the reaction k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com