Patents

Literature

56 results about "Beta hydroxybutyrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

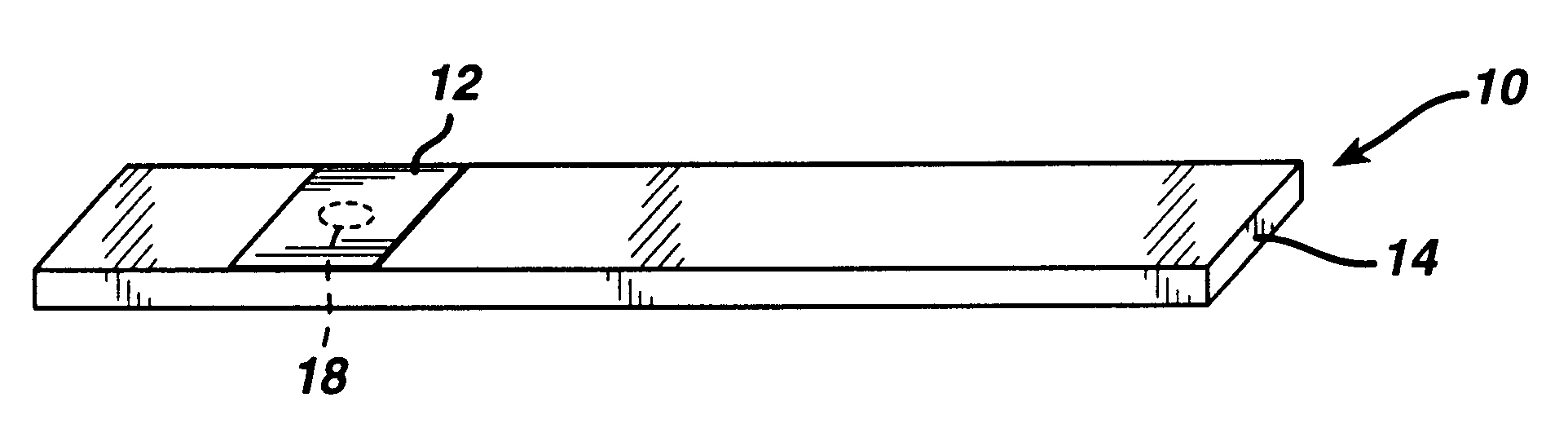

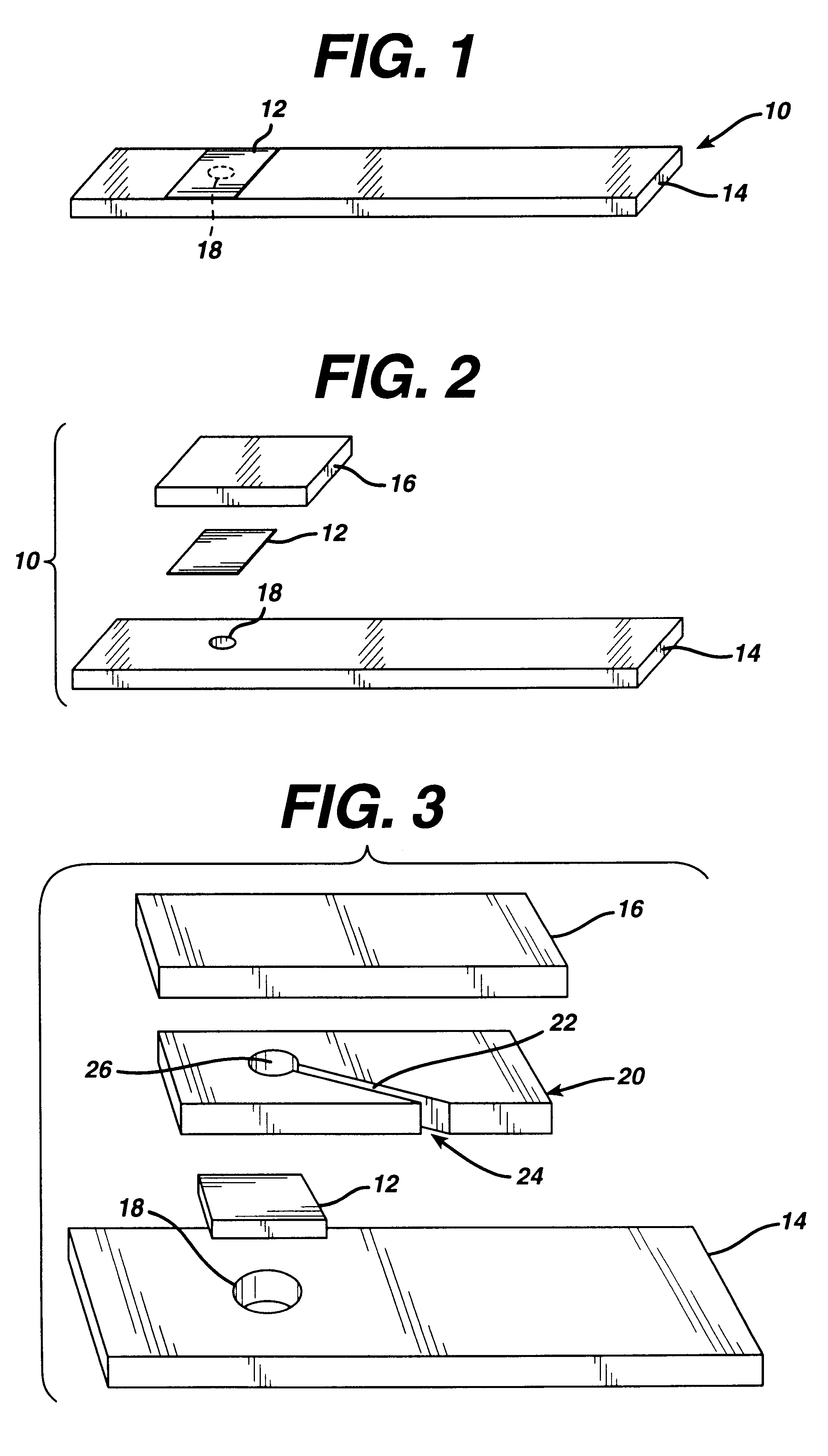

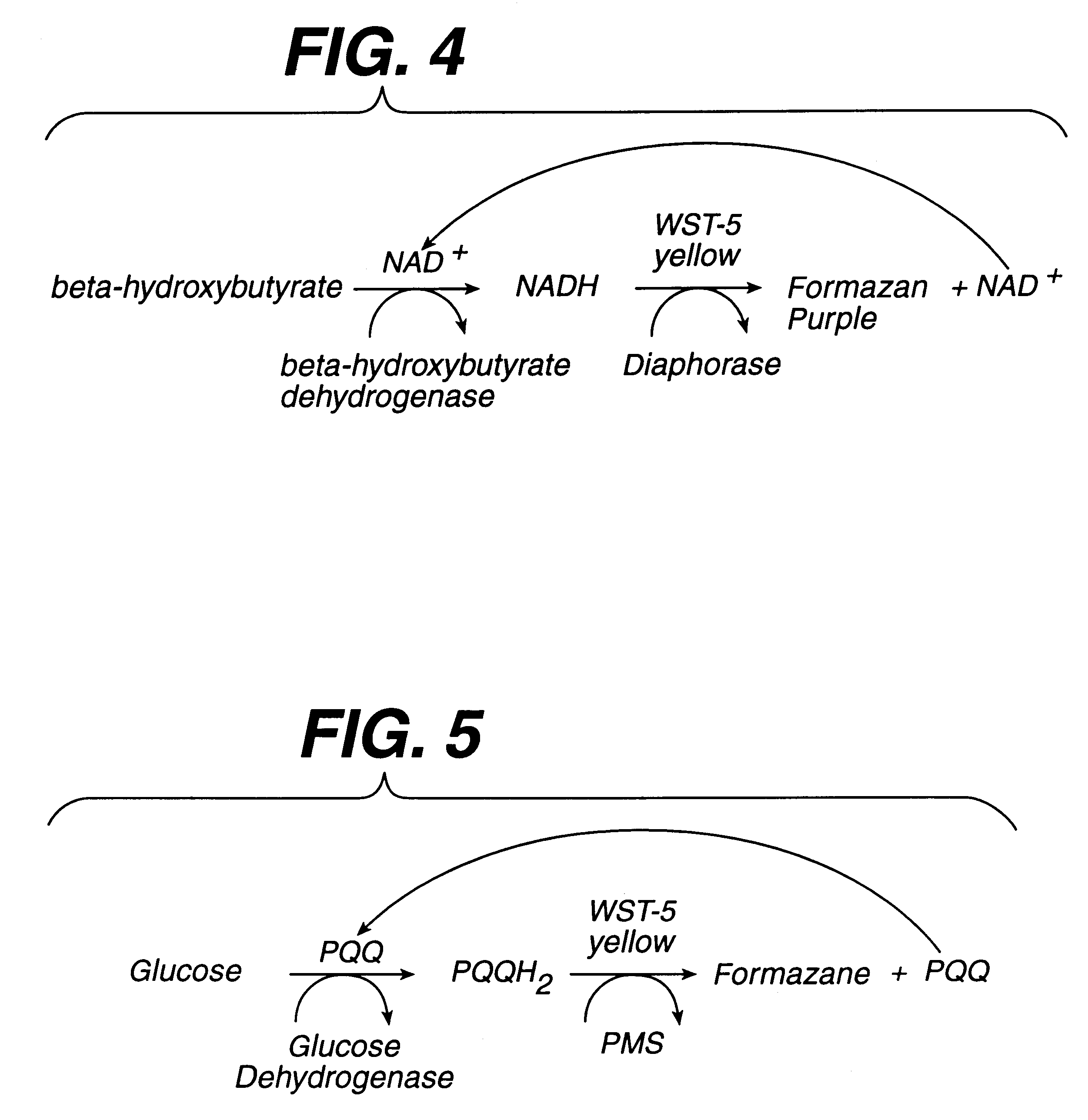

Diagnostics based on tetrazolium compounds

InactiveUS6200773B1Bioreactor/fermenter combinationsOrganic chemistryPyrrolo-Quinoline QuinoneDiaphorase

A reagent is suitable for measuring the concentration of an analyte in a hemoglobin-containing biological fluid, such as whole blood. The reagent comprises dehydrogenase enzyme that has specificity for the analyte, NAD, an NAD derivative, pyrrolo-quinoline quinone (PQQ), or a PQQ derivative, a tetrazolium dye precursor, a diaphorase enzyme or an analog thereof, and a nitrite salt. The reagent causes dye formation that is a measure of the analyte concentration. The nitrite salt suppresses interfering dye formation caused non-enzymatically by the hemoglobin. Preferably, the reagent is used in a dry strip for measuring ketone bodies, such as beta-hydroxybutyrate.

Owner:LIFESCAN IP HLDG LLC

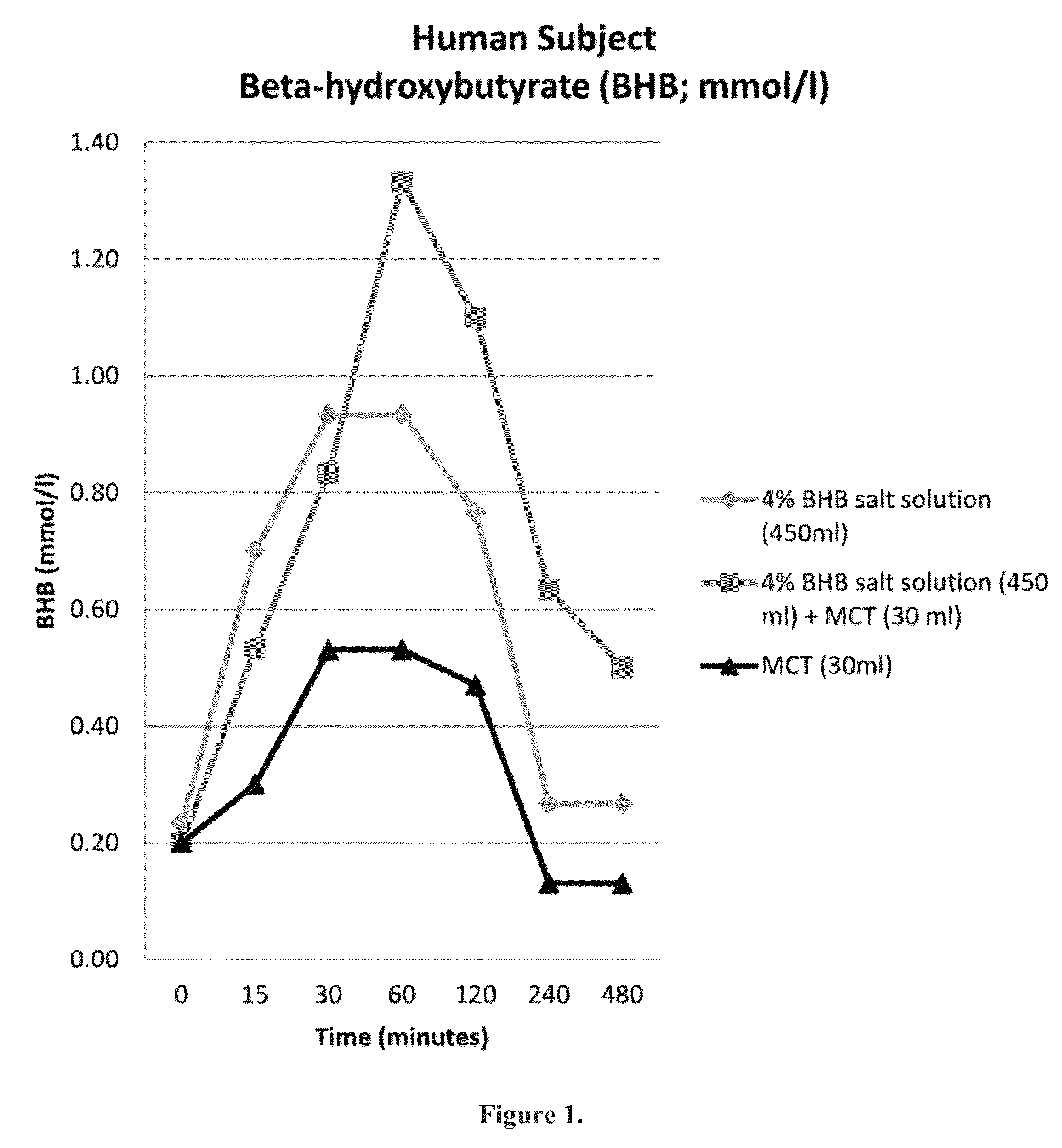

Compositions and methods for producing elevated and sustained ketosis

ActiveUS9138420B2Rapid and sustained elevationImprove the level ofHydroxy compound active ingredientsMetabolism disorderSignificant elevationKetogenic diet

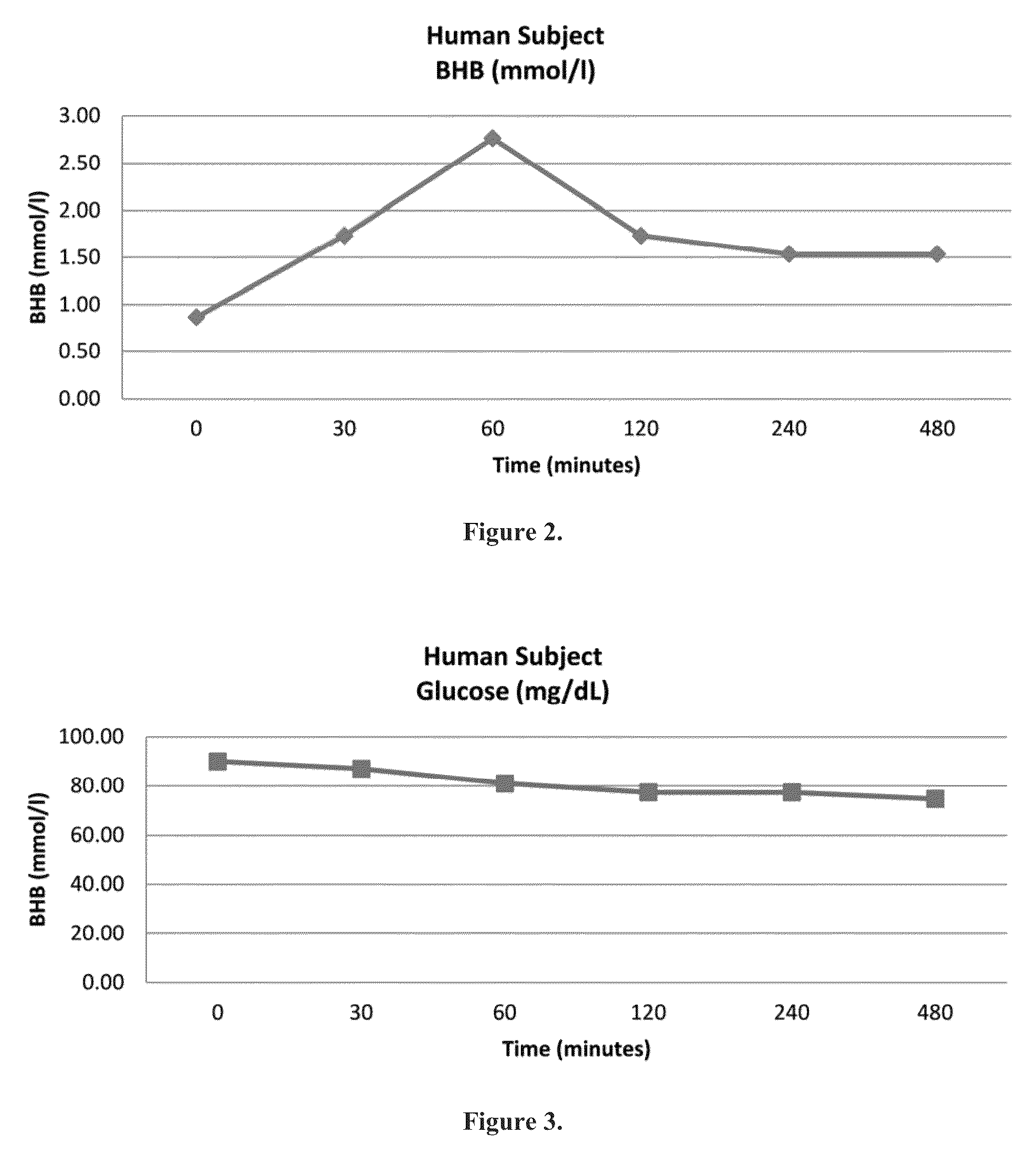

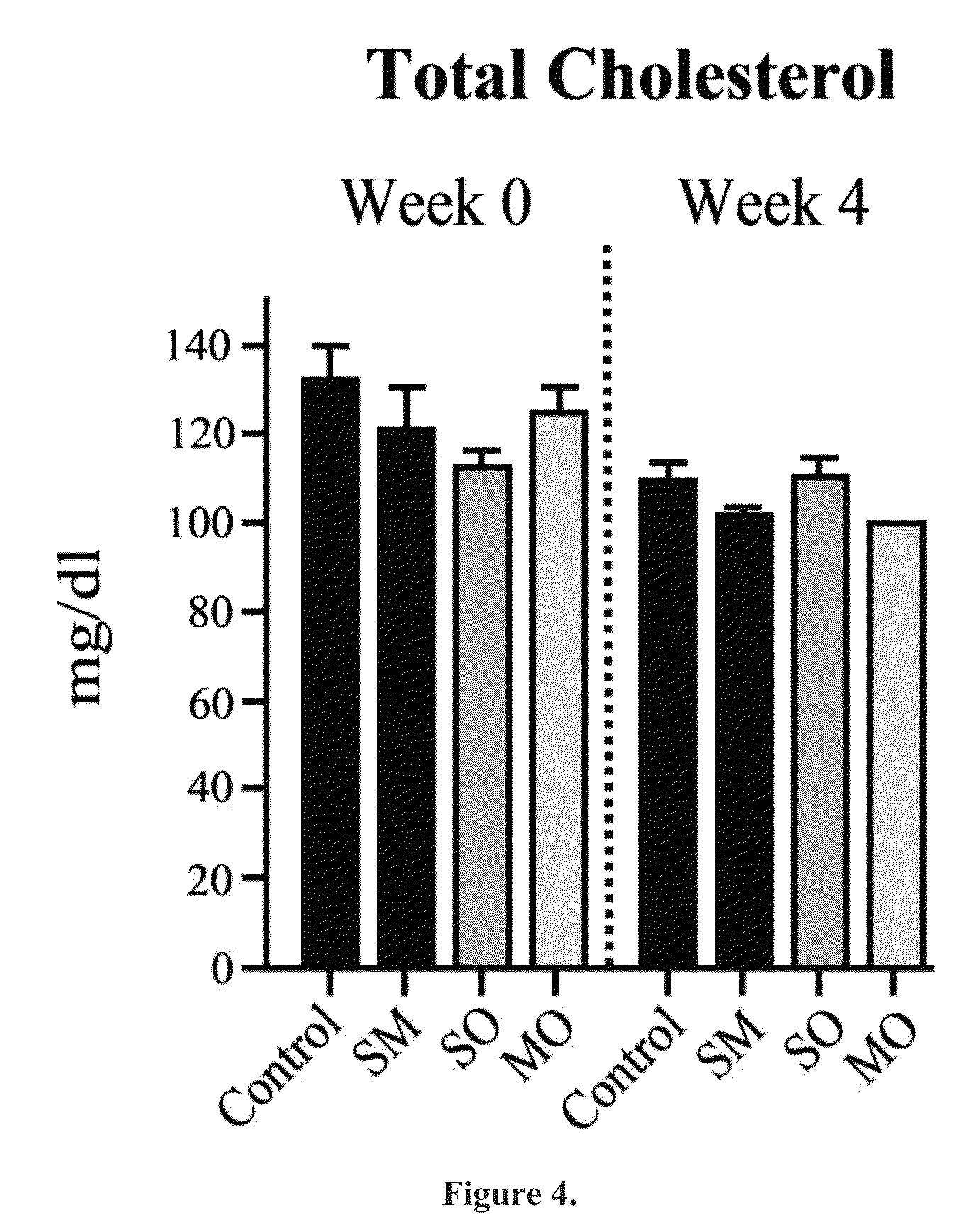

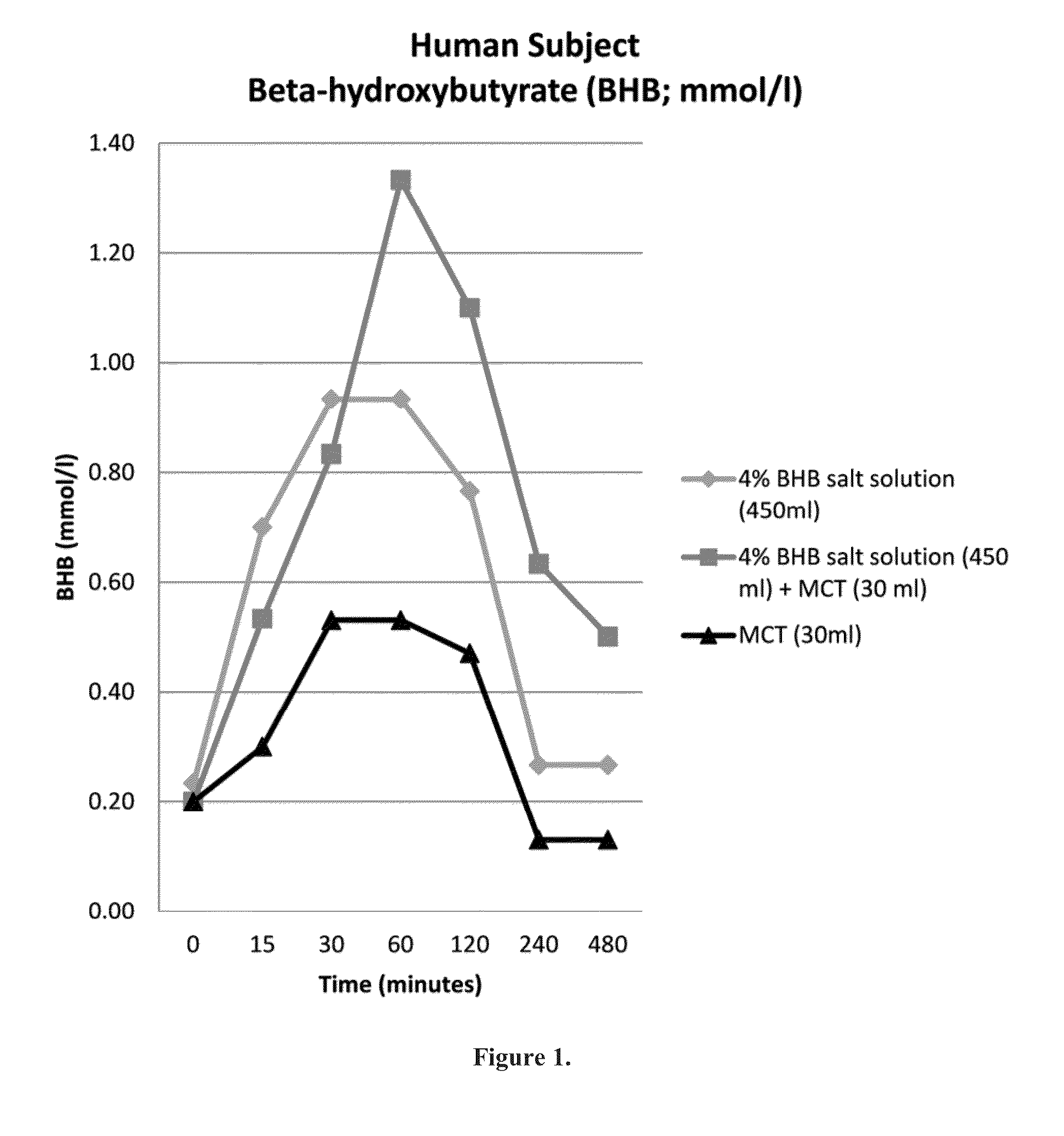

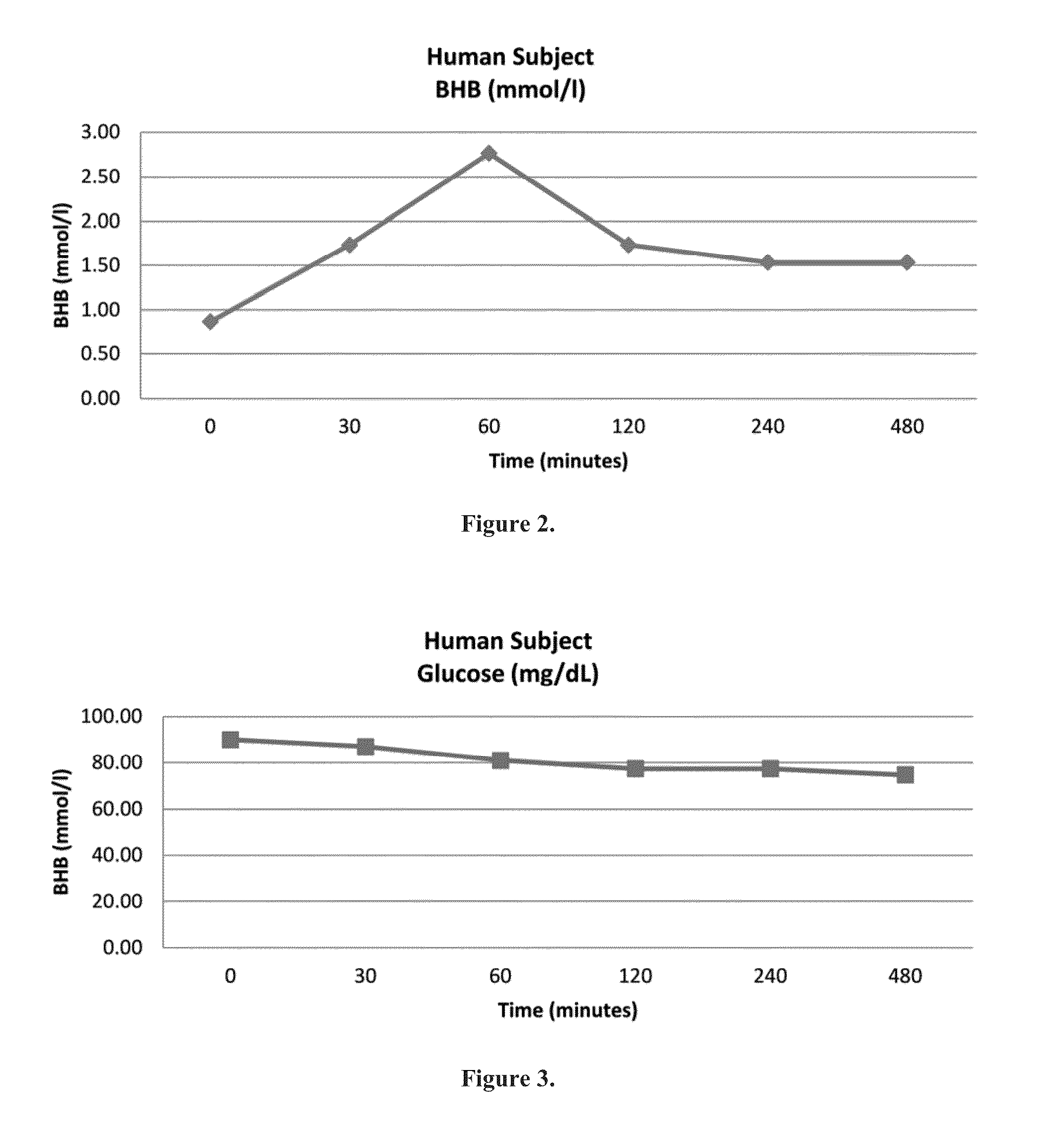

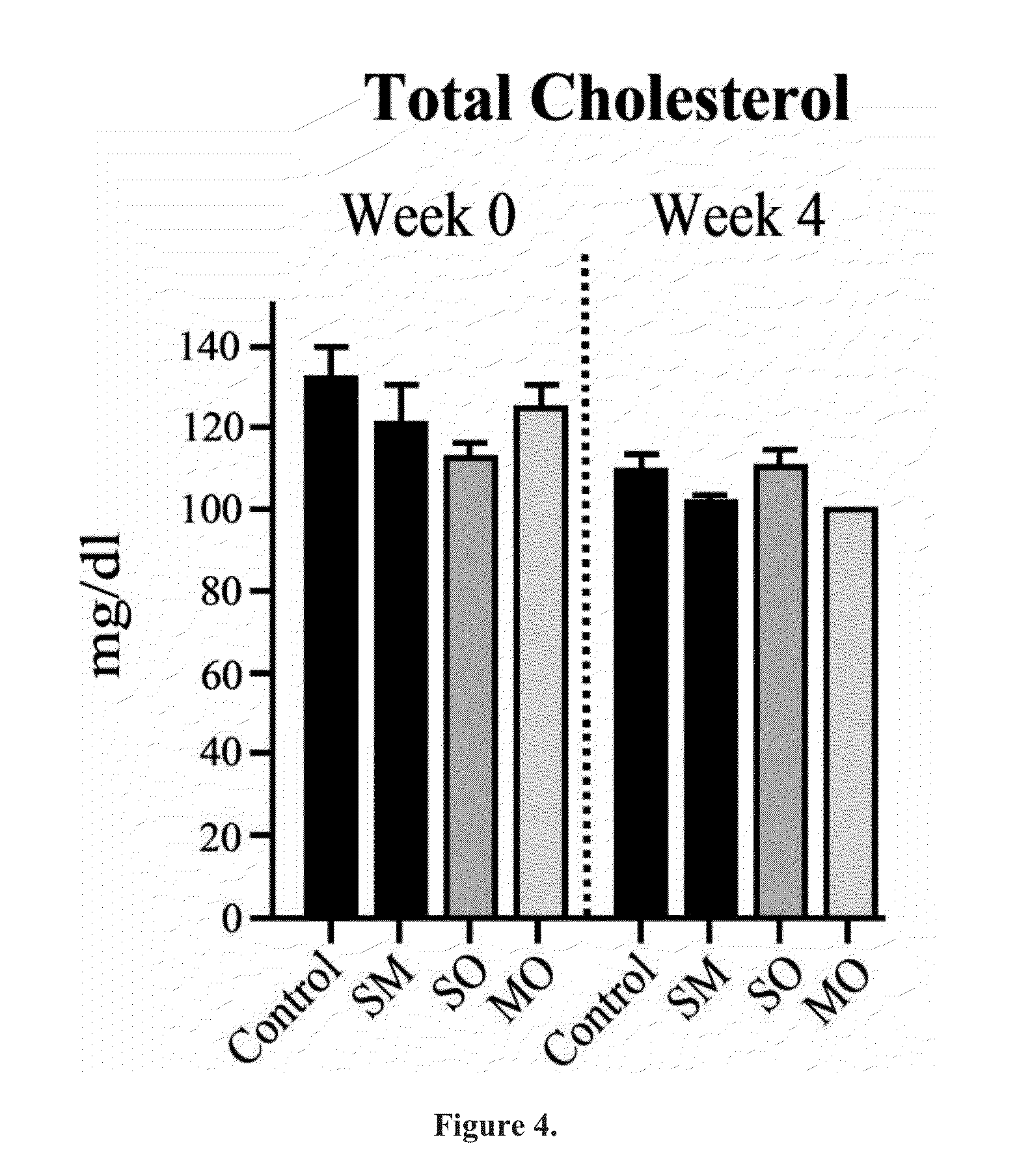

Beta-hydroxybutyrate mineral salts in combination with medium chain fatty acids or an ester thereof such as medium chain triglycerides were used to induce ketosis, achieving blood ketone levels of (2-7 mmol / L), with or without dietary restriction. The combination results in substantial improvements in metabolic biomarkers related to insulin resistance, diabetes, weight loss, and physical performance in a short period of time. Further, use of these supplements to achieve ketosis yields a significant elevation of blood ketones and reduction of blood glucose levels. Use of these substances does not adversely affect lipid profiles. By initiating rapid ketosis and accelerating the rate of ketoadaptation, this invention is useful for the avoidance of glucose withdrawal symptoms commonly experienced by individuals initiating a ketogenic diet, and minimizes the loss of lean body mass during dietary restriction.

Owner:UNIV OF SOUTH FLORIDA

Compositions and methods for producing elevated and sustained ketosis

ActiveUS20140350105A1Rapid and sustained elevationImprove metabolic healthBiocideHydroxy compound active ingredientsKetoneSignificant elevation

Beta-hydroxybutyrate mineral salts in combination with medium chain fatty acids or an ester thereof such as medium chain triglycerides were used to induce ketosis, achieving blood ketone levels of (2-7 mmol / L), with or without dietary restriction. The combination results in substantial improvements in metabolic biomarkers related to insulin resistance, diabetes, weight loss, and physical performance in a short period of time. Further, use of these supplements to achieve ketosis yields a significant elevation of blood ketones and reduction of blood glucose levels. Use of these substances does not adversely affect lipid profiles. By initiating rapid ketosis and accelerating the rate of ketoadaptation, this invention is useful for the avoidance of glucose withdrawal symptoms commonly experienced by individuals initiating a ketogenic diet, and minimizes the loss of lean body mass during dietary restriction.

Owner:UNIV OF SOUTH FLORIDA

System for optimizing the production performance of a milk producing animal herd

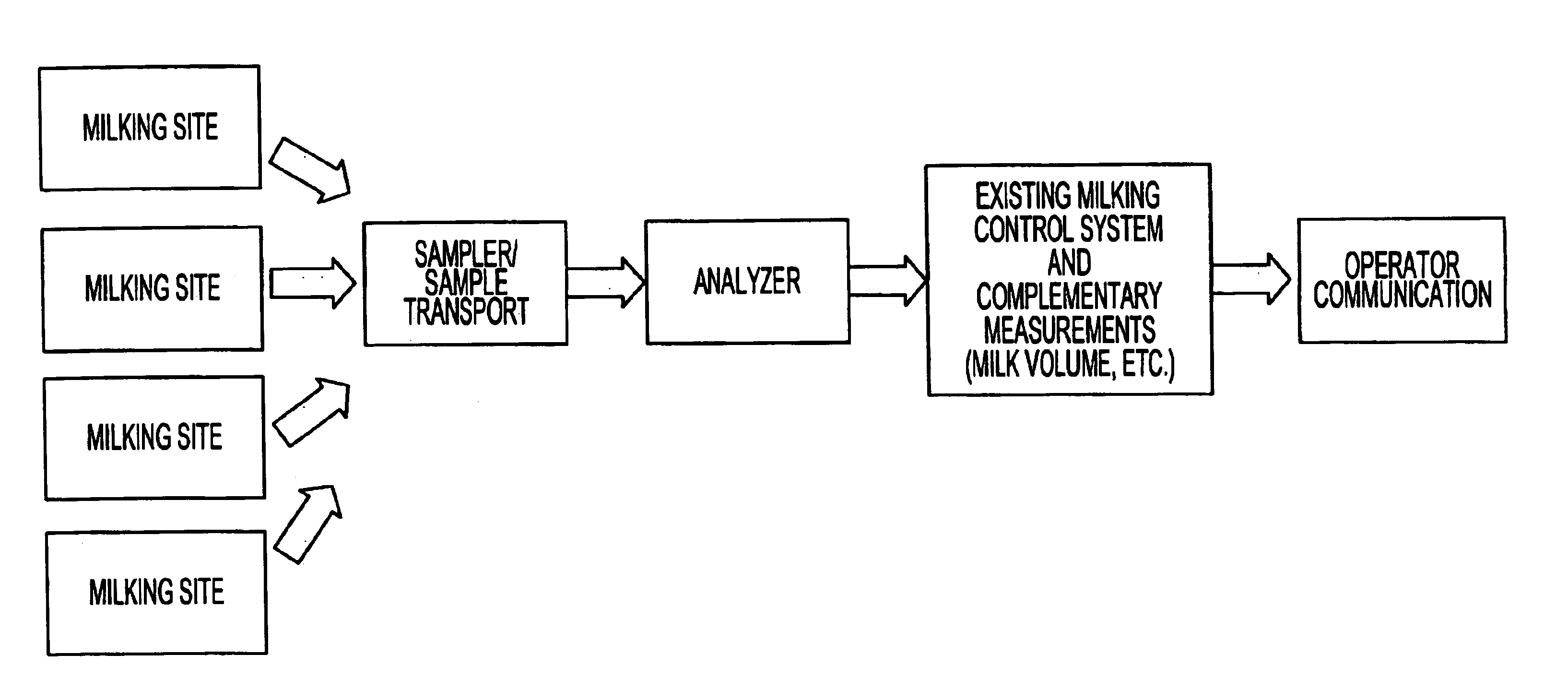

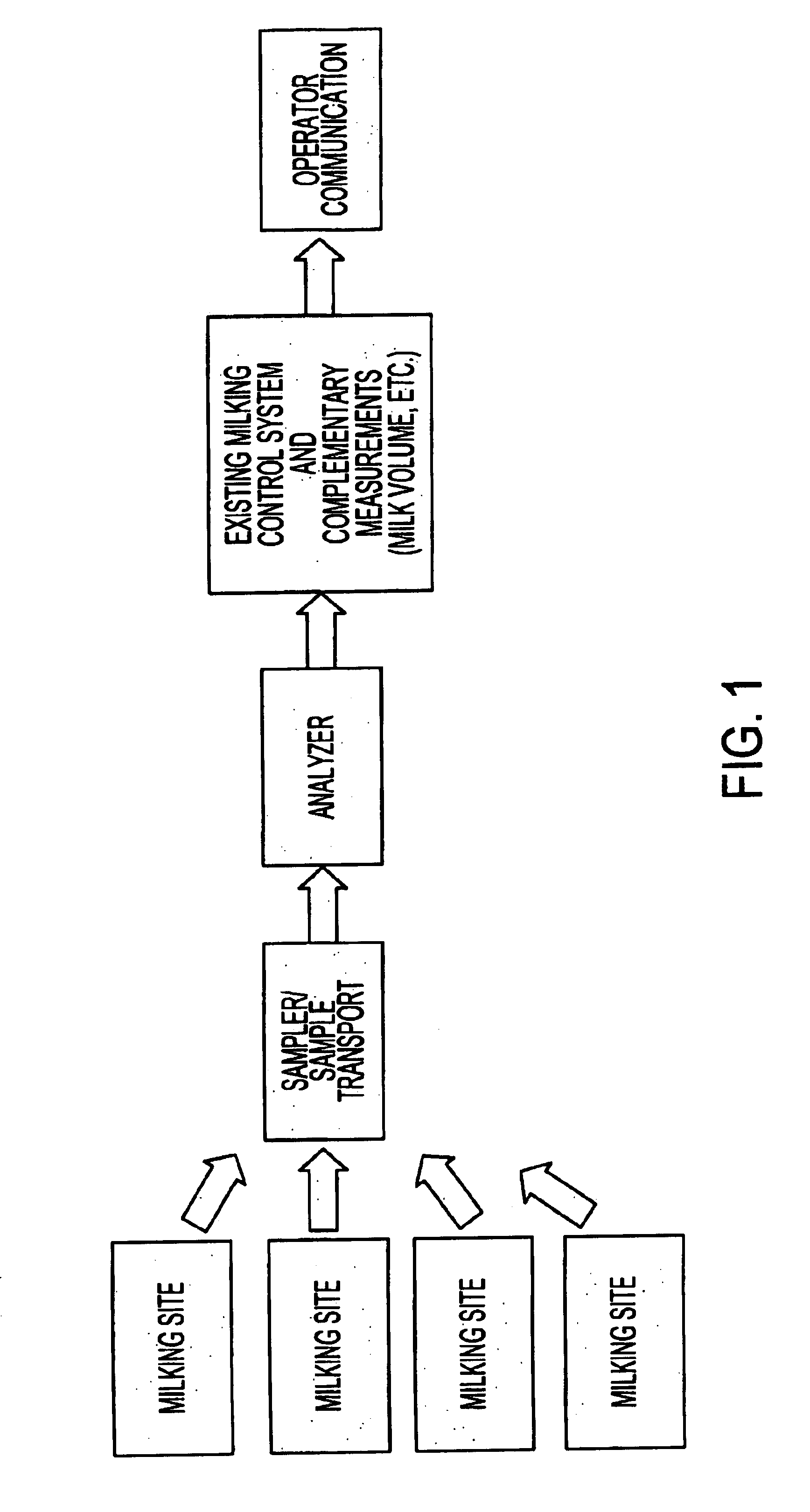

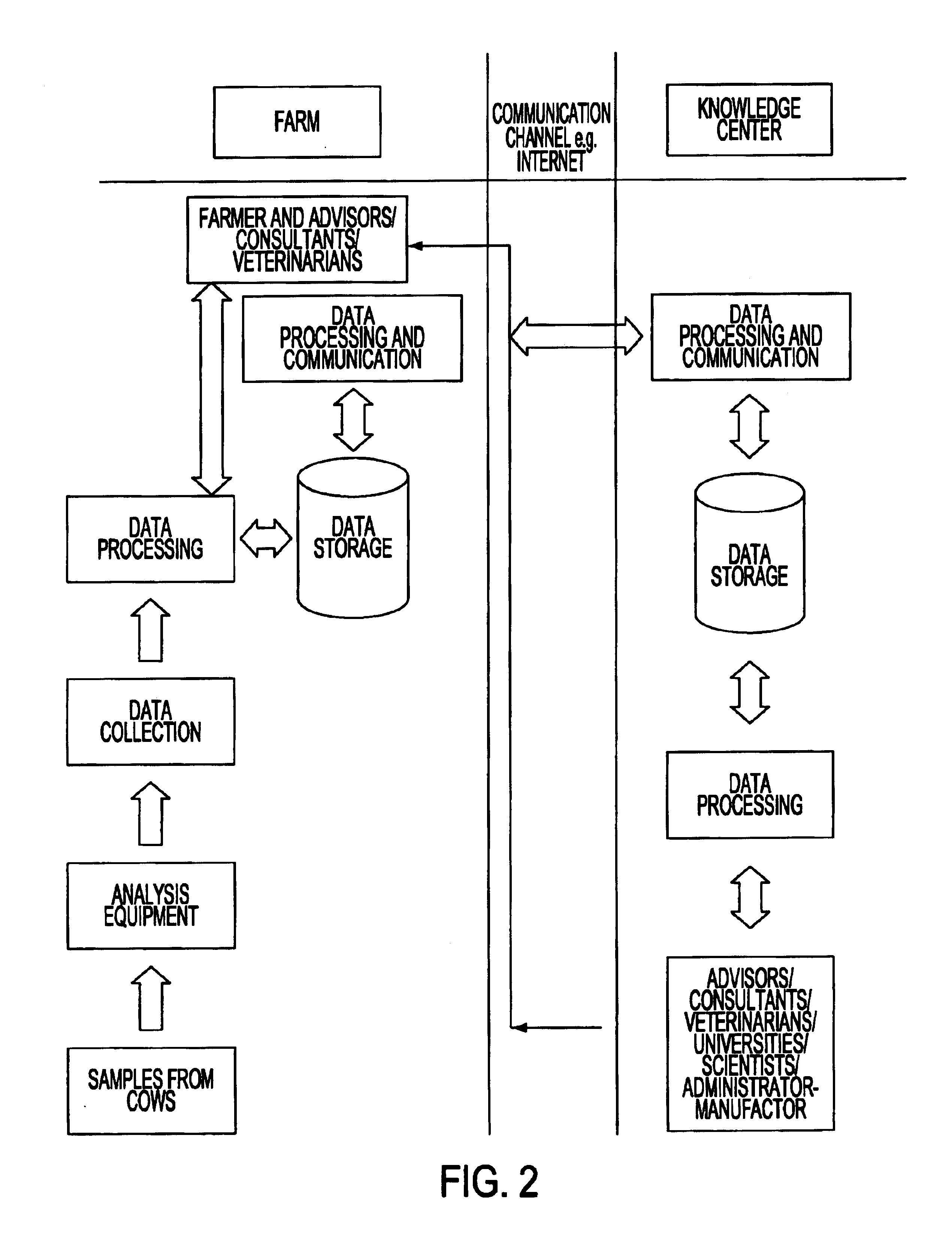

InactiveUS6814025B2Increase productivityIncrease profitabilitySamplingCathetersLactate dehydrogenaseAgricultural science

Owner:LATTEC

Mixed salt compositions for producing elevated and sustained ketosis

ActiveUS20170258745A1Improved metabolic healthLimiting, preventing, or improving an electrolyte imbalancePowder deliveryDispersion deliveryPotassiumExcipient

Ketogenic compositions including a beta-hydroxybutyrate (BHB) mixed salt are formulated to induce or sustain ketosis in a subject to which the ketogenic compositions are administered. The BHB mixed salt is formulated to provide a biologically balanced set of cationic electrolytes, and is formulated to avoid detrimental health effects associated with imbalanced electrolyte ratios. A ketogenic composition includes BHB salts of at least sodium, potassium, calcium, and magnesium. The BHB salts may also include at least other component such as a BHB compound containing other cations, such as transition metal cations (e.g., zinc or iron), a BHB-amino acid salts, medium chain fatty acid source, vitamin D3, flavorant, or other excipient.

Owner:AXCESS GLOBAL SCI LLC

Method for preparing composite board capable of simultaneously slowly releasing nitrogen and adsorbing/biologically degrading petroleum hydrocarbons

InactiveCN102976499AImprove processing efficiencyCause secondary pollutionWater contaminantsBiological water/sewage treatmentEcological environmentPolyethylene glycol

The invention discloses a method for preparing a composite board capable of simultaneously slowly releasing nitrogen and adsorbing / biologically degrading petroleum hydrocarbons. The method comprising the steps of weighing urea aqueous solution and formaldehyde aqueous solution in the proportion of 6.5:1 and regulating the pH value of the urea aqueous solution to 7.2-7.4; adding formaldehyde into the urea aqueous solution, stirring, regulating the pH value to 3.2-3.4 and adding deionized water to obtain a mixed solution M1; mixing poly(beta-hydroxybutyrate) and chloroform solution of polyethylene glycol in the proportion of 5:1; dropwise adding the M1 into the mixed chloroform solution in the proportion of 1:4; spraying distilled water into a container filled with liquid nitrogen to manufacture ice ball particles, screening, and putting in a mould to compact; pouring the mixed solution into the mould, carrying out freezing shaping and obtaining a composite board after demoulding and freezing; and culturing the composite board in a petroleum hydrocarbon degrading bacteria solution for 24h, drying in the air and obtaining the composite board capable of simultaneously slowly releasing nitrogen and adsorbing / biologically degrading petroleum hydrocarbons. The method disclosed by the invention has the advantages that the manufacturing process is simple; and the obtained composite board is high in petroleum hydrocarbon pollutant treating efficiency and incapable of causing secondary pollution and damage to the water ecological environment.

Owner:BEIJING NORMAL UNIVERSITY

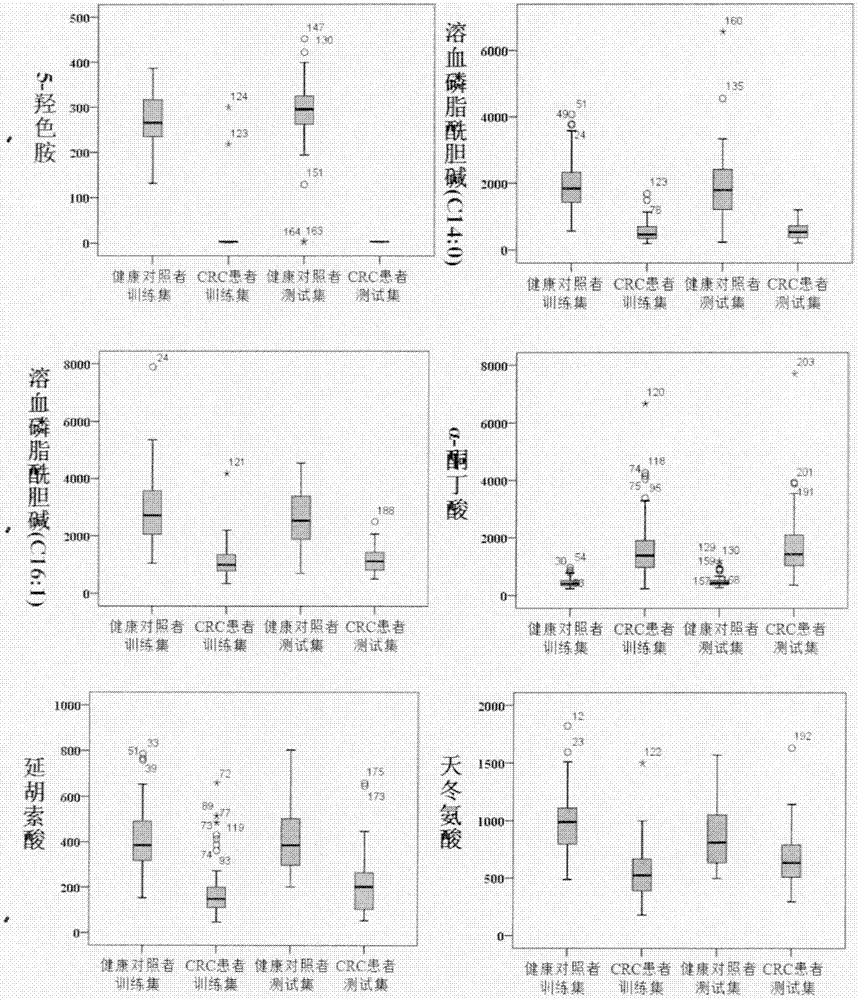

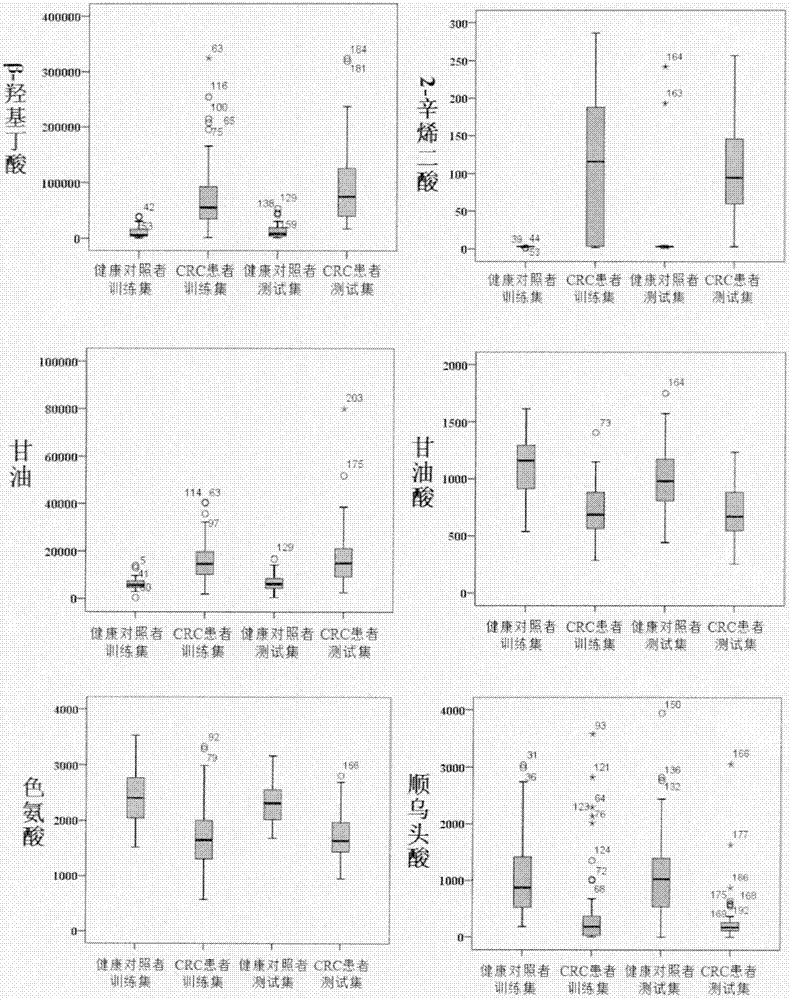

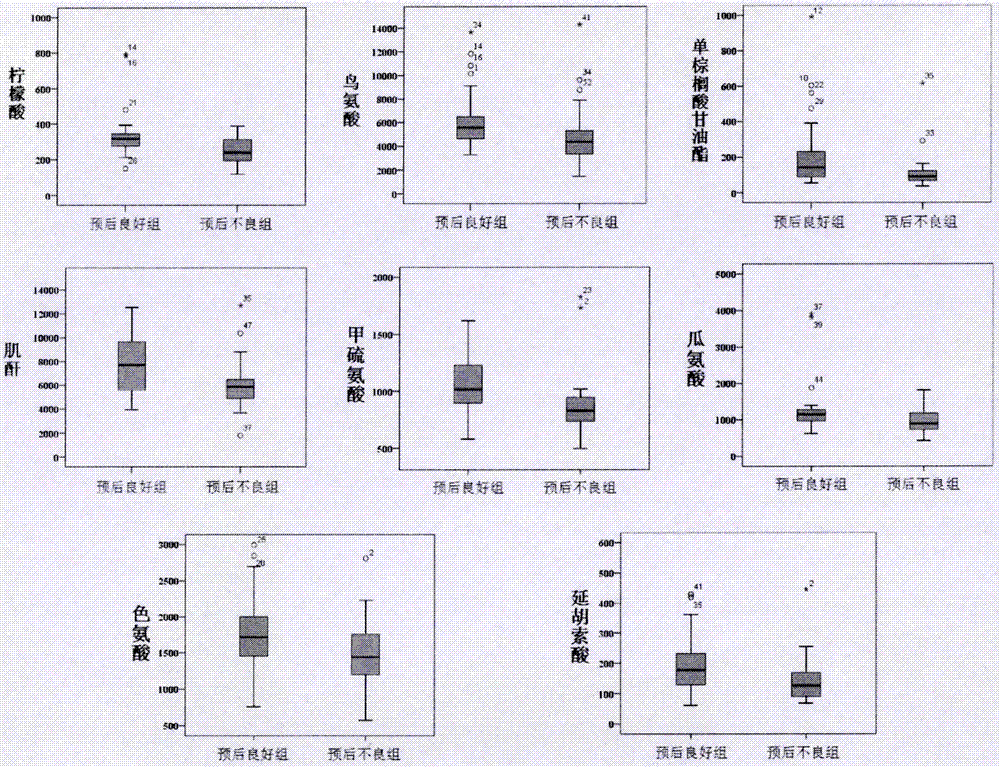

Molecular marker with auxiliary functions of early diagnosis and prognosis monitoring on colorectal cancer, and application thereof

Owner:SHENZHEN UNIV

Mixed salt compositions for producing elevated and sustained ketosis

ActiveUS20190167613A1Limiting, preventing, or improving an electrolyte imbalanceImprove balancePowder deliveryDispersion deliveryPotassiumExcipient

Ketogenic compositions including a beta-hydroxybutyrate (BHB) mixed salt are formulated to induce or sustain ketosis in a subject to which the ketogenic compositions are administered. The BHB mixed salt is formulated to provide a biologically balanced set of cationic electrolytes, and is formulated to avoid detrimental health effects associated with imbalanced electrolyte ratios. A ketogenic composition includes BHB salts of at least sodium, potassium, calcium, and magnesium. The BHB salts may also include at least other component such as a BHB compound containing other cations, such as transition metal cations (e.g., zinc or iron), a BHB-amino acid salts, medium chain fatty acid source, vitamin D3, flavorant, or other excipient.

Owner:AXCESS GLOBAL SCI LLC

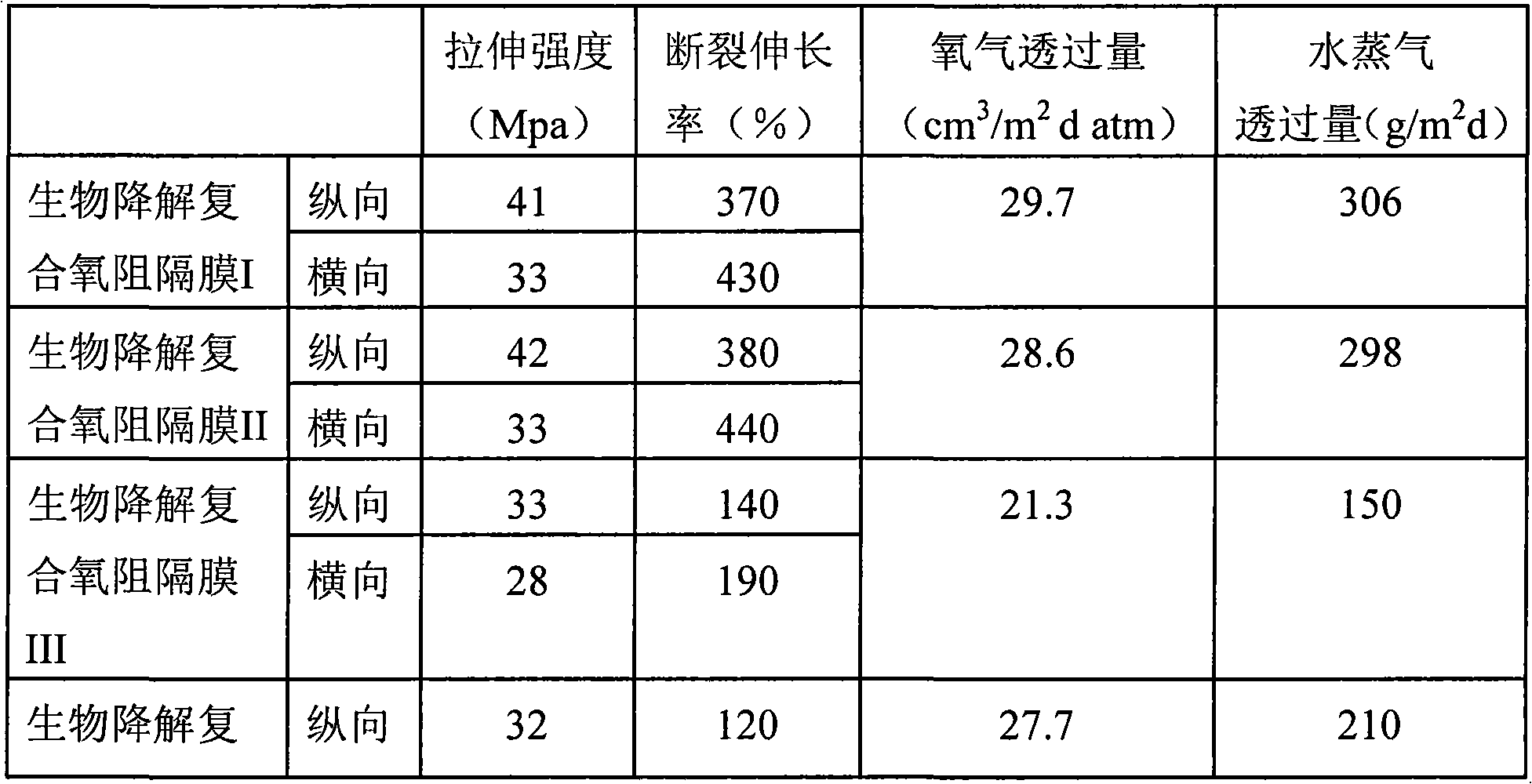

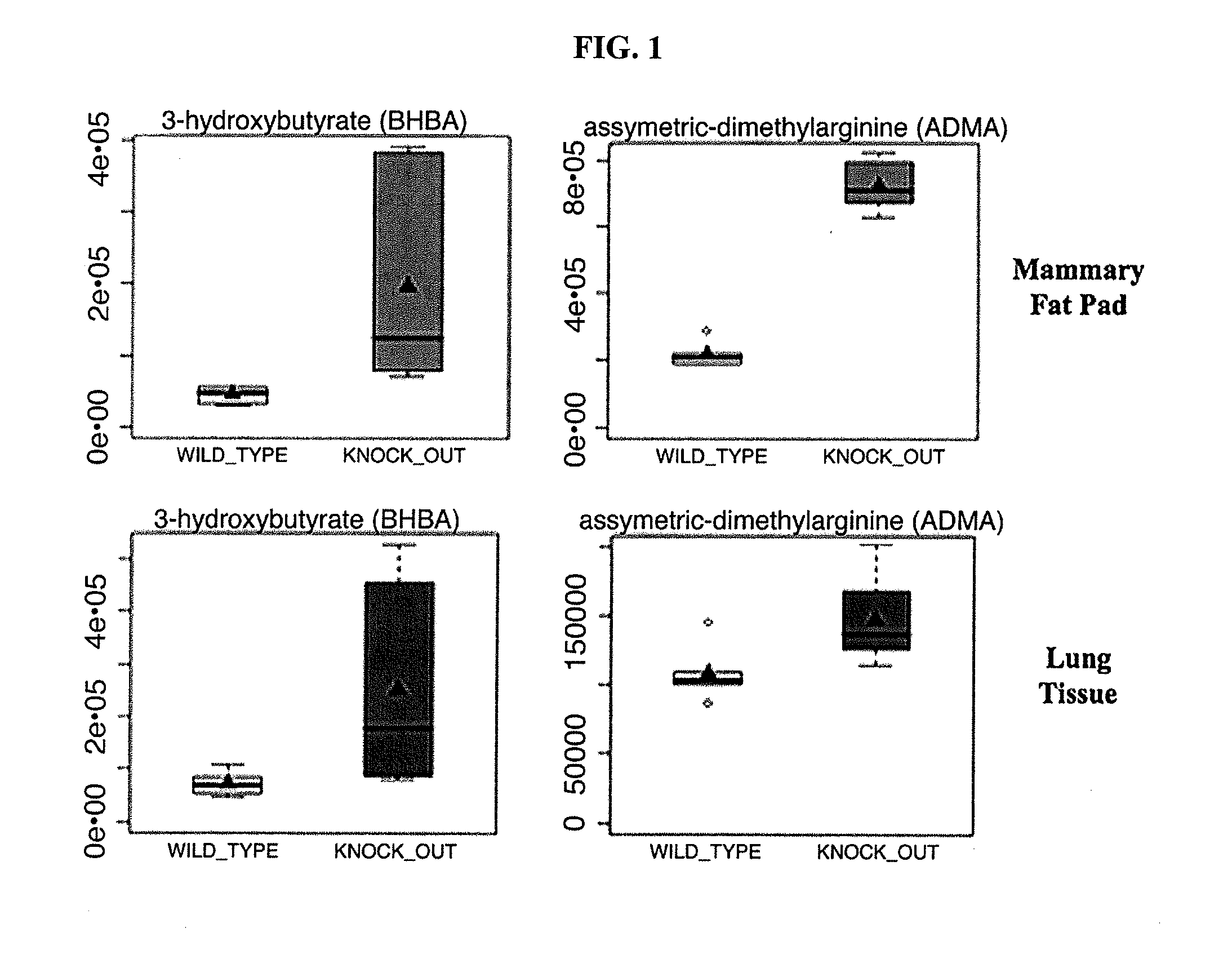

Biodegradable composite oxygen-barrier film and use thereof

ActiveCN102007001AExtended shelf lifeExtend your lifeFlexible coversWrappersEngineeringPoly(butylene succinate)

The invention discloses a biodegradable composite oxygen-barrier film and its preparation method and use. The biodegradable composite oxygen-barrier film is composed of at least two support layers and barrier layer which is located in each of the two support layers. Said support layer is selected from at least one of the following materials: polylactic acid, polybutylene succinate, polycaprolactone, poly(butylene adipate-co-terephthalate), poly(beta-hydroxybutyrate) and poly(beta-hydroxybutyrate-co-hydroxyvalerate); said barrier layers located in each of the two support layers are same or different, and the barrier layer is selected from poly(1,2-propylene carbonate) and nano-montmorillonite modified poly(1,2-propylene carbonate). The biodegradable composite oxygen-barrier film can be used as food or medicine package, and it will help to prolong shelf-life of food and medicine and the like; it can also prevent white-pollution.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Mixed salt compositions for maintaining or restoring electrolyte balance while producing elevated and sustained ketosis

ActiveUS10292952B2Limiting, preventing, or improving an electrolyte imbalanceImprove balanceMetabolism disorderEster active ingredientsPotassiumKetone

Ketogenic compositions including a beta-hydroxybutyrate (BHB) mixed salt are formulated to induce or sustain ketosis in a subject to which the ketogenic compositions are administered. The BHB mixed salt is formulated to provide a biologically balanced set of cationic electrolytes, and is formulated to avoid detrimental health effects associated with imbalanced electrolyte ratios. A ketogenic composition includes BHB salts of at least sodium, potassium, calcium, and magnesium. The BHB salts may also include at least other component such as a BHB compound containing other cations, such as transition metal cations (e.g., zinc or iron), a BHB-amino acid salts, medium chain fatty acid source, vitamin D3, flavorant, or other excipient.

Owner:AXCESS GLOBAL SCI LLC

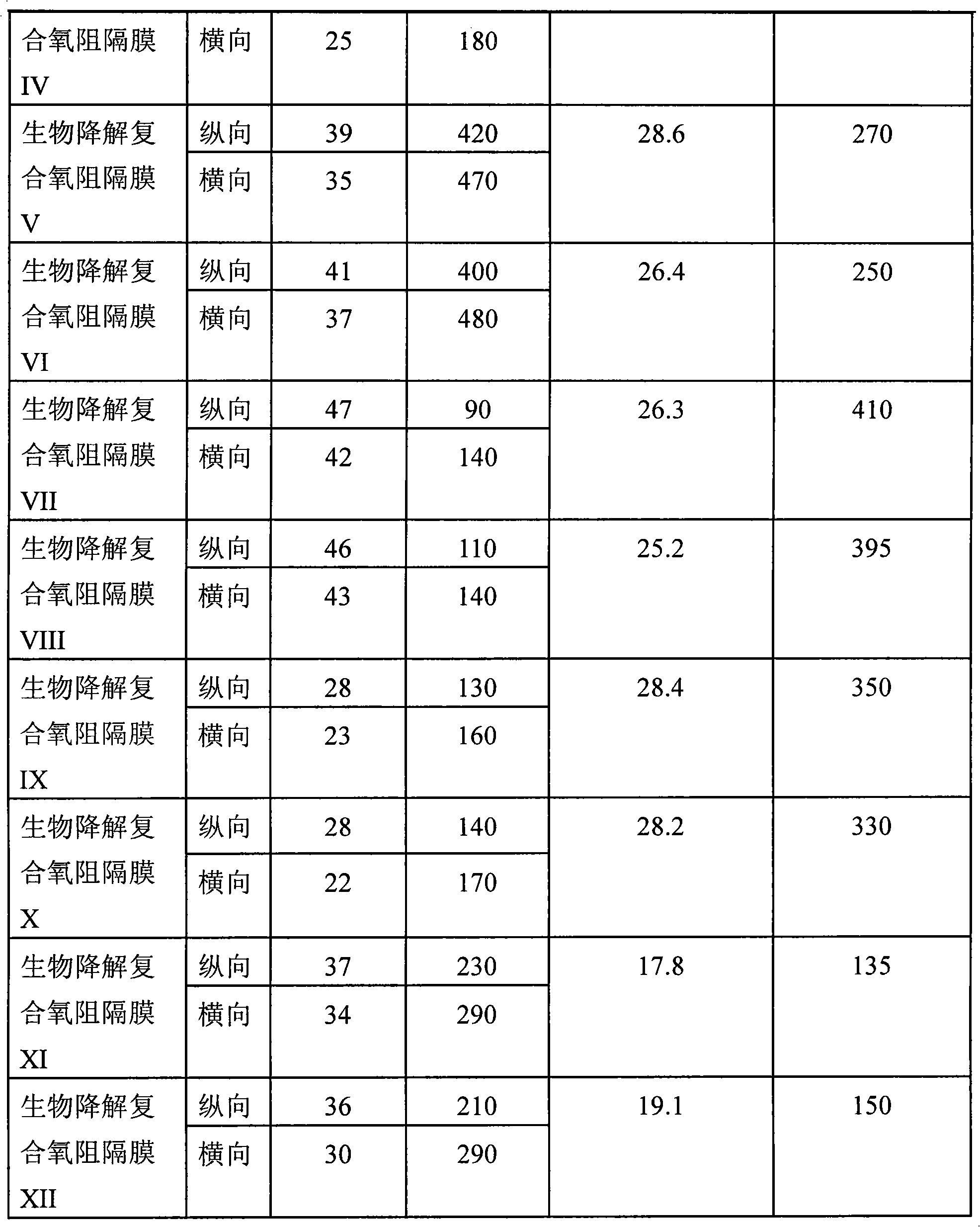

Prognosis and treatment of breast cancer

Methods of prognosis and monitoring of breast cancer include determining the level of one or more of the markers comprising asymmetric dimethyl arginine (ADMA), beta-hydroxybutyrate (BHB) and microRNA-31 (miR-31) in patient samples. An increased level is correlated with poor prognosis. Breast cancer is treated by administration of one or more inhibitors of ADMA and / or BHB.

Owner:THOMAS JEFFERSON UNIV

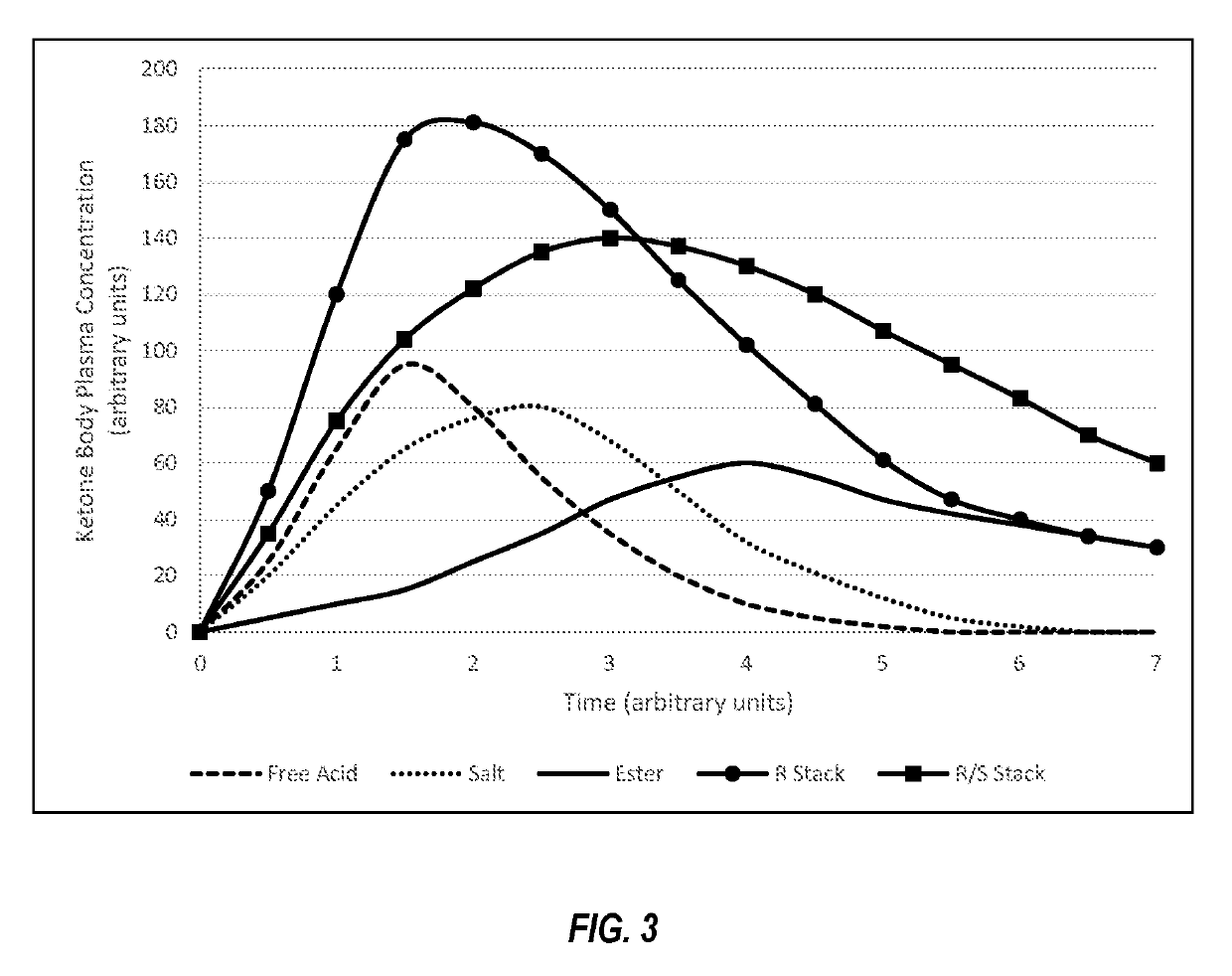

Non-racemic beta-hydroxybutyrate compounds and compositions enriched with the s-enantiomer and methods of use

ActiveUS20190183820A1Few or no effectsImprove the level ofPowder deliveryMetabolism disorderPhysiologyKetosis

Ketogenic compositions including a non-racemic mixture of beta-hydroxybutyrate (BHB) enriched with the S-enantiomer are formulated to control ketone body levels in a subject. The non-racemic mixture of BHB is enriched with the S-enantiomer to modulate the effect of ketone bodies in the subject and control the rate at which ketosis is achieved. In some aspects a composition for controlling ketone body level in a subject contains a dietetically or pharmaceutically acceptable carrier and a non-racemic mixture of S-beta-hydroxybutyrate and R-beta-hydroxybutyrate, wherein the non-racemic mixture contains from about 52% to 99% by enantiomeric equivalents of S-beta-hydroxybutyrate enantiomer and from about 48% to about 1% by enantiomeric equivalents of R-beta-hydroxybutyrate enantiomer.

Owner:AXCESS GLOBAL SCI LLC

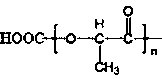

Synthesis of degradable poly-beta-oxybate

The method for synthesizing completely-degradable plastics poly beta-hydroxybutyrate includes the folloiwng steps: adopting acetaldehyde as raw material to prepare beta-hydroxybutanal; oxidizing it to prepare beta-hydroxybutyric acid; esterifying it to prepare ethyl beta-hydroxybutyrate and polymerizing it to prepare poly beta-hydroxybutyrate. It is characterized by that preparation of beta-hydroxybutanal adopts benzene as solvent, sodium hydroxide as catalyst, its reaction temp. is 1-15 deg.C and the organic acid is used as neutralizing reagent, the preparation of beta-hydroxybutyric acid adopts ethyl acetate as solvent, cobalt acetate as catalyst, its reaction temp. is 40-100 deg.c and reaction pressure is 0.3-1.5 MPa, the preparation of ethyl ebeta-hydroxybutyrate adopts cresulsulfonicacid as catalyst and ethyl alcohol as solvent and polymerization preparation of beta-hydroxybutyrate uses isopropyl titanate as catalyst.

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI +1

Degradable food packaging film material and preparation technology thereof

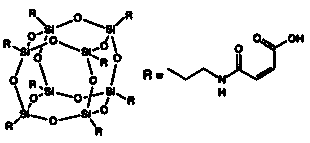

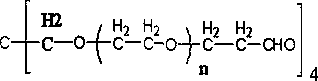

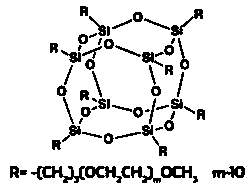

ActiveCN110387112AHigh tear strengthGuaranteed uniformityFlexible coversWrappersPolyesterPolyethylene glycol

The invention provides a degradable food packaging film material and a preparation technology thereof, and relates to a high-strength-and-ductility fully-degradable biopolyester composite and a preparation technology thereof. The degradable food packaging film material is characterized by being prepared by taking aliphatic polycarbonate, lactic acid, poly(beta-hydroxybutyrate-co-beta-hydroxyvalerate), 4-arm-polyethylene glycol propionaldehyde, chitosan, 8-arm polyethylene glycol polyhedral oligomeric silsesquioxane, stannous octoate, stannous chloride, a melt reinforcing agent and an antioxidant as raw materials in a reaction extrusion mode. The biomass composite is simple in processing technology, has excellent strength and ductility, can be fully degraded, and can be suitable for packaging and industrial fields requiring high strength and ductility.

Owner:浙江多赢新材料科技有限公司

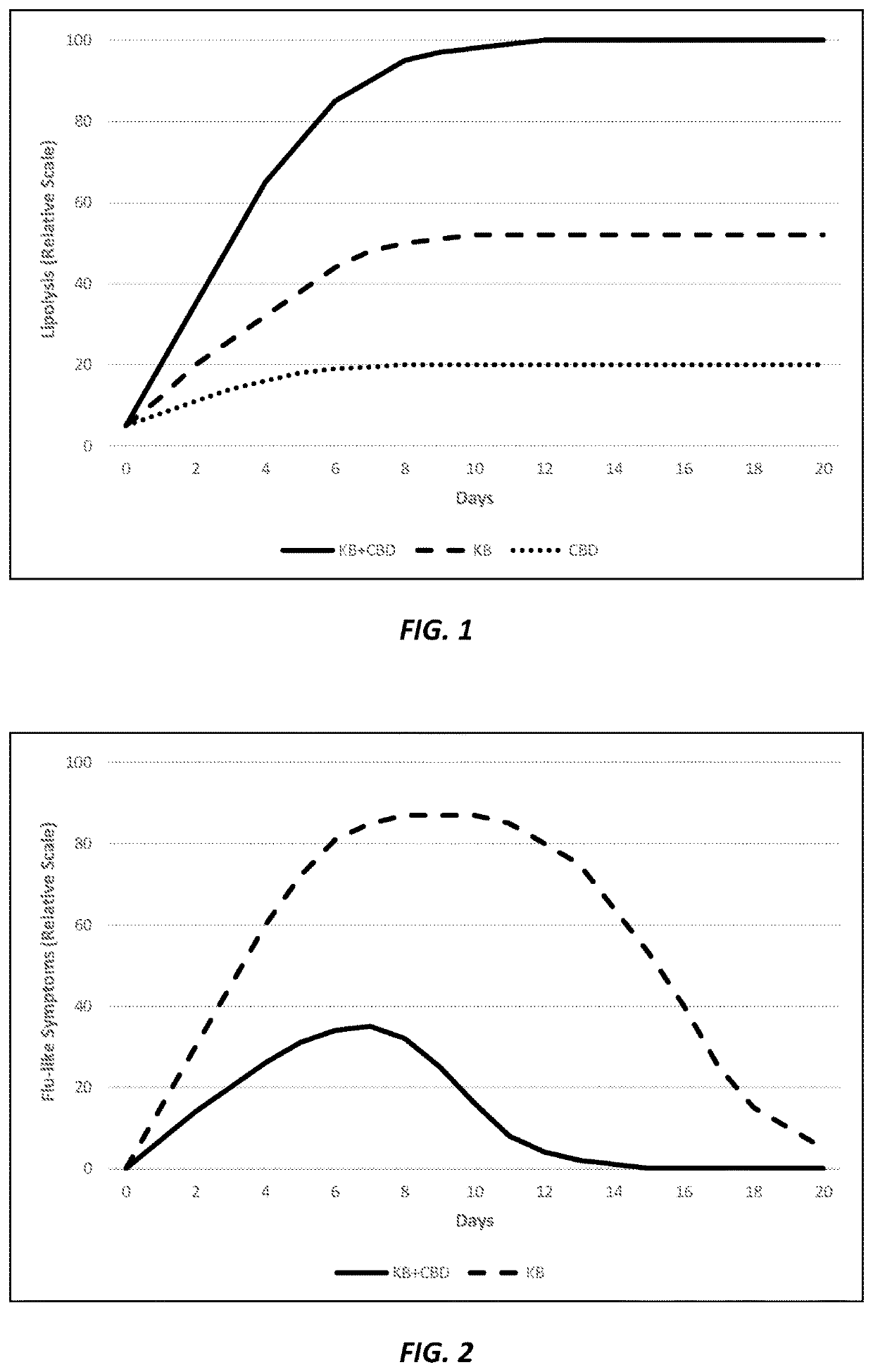

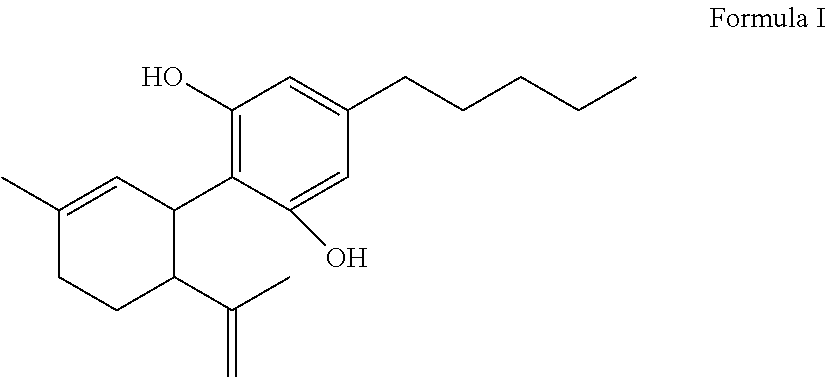

Compositions and methods for delivering cannabidiol and ketone bodies

ActiveUS10512615B1Shorten the durationReduce severityHydroxy compound active ingredientsPharmaceutical non-active ingredientsAcetoacetatesMammal

Disclosed herein are “ketonnabidiol” compositions including a combination of: (1) cannabidiol (CBD) and / or cannabidiolic acid (CBDA); (2) a ketone body component such as beta-hydroxybutyrate (BHB) and / or acetoacetate; and (3) a dietetically or pharmaceutically acceptable carrier. Also disclosed herein are methods of using such ketonnabidiol compositions for producing desired physiological effects, such as fat loss, in a mammal. The ketonnabidiol compositions beneficially enhance fat loss through ketosis while also reducing the duration and / or severity of unpleasant “keto flu” symptoms typically associated with ketosis.

Owner:AXCESS GLOBAL SCI LLC

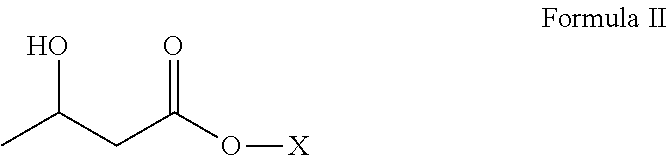

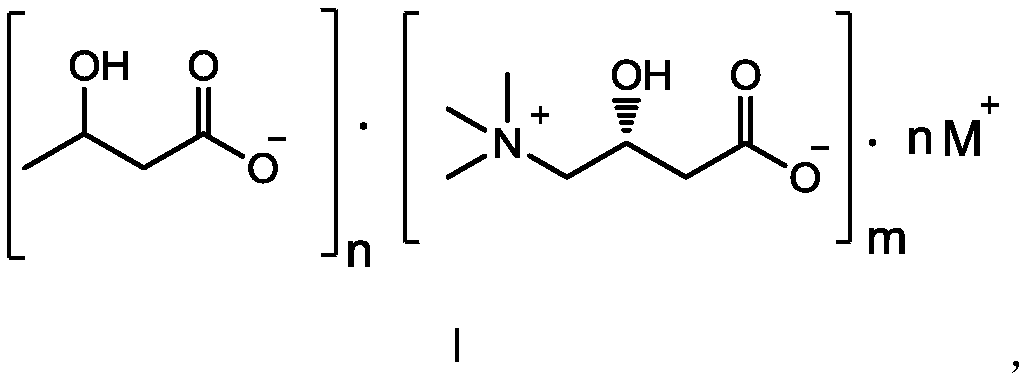

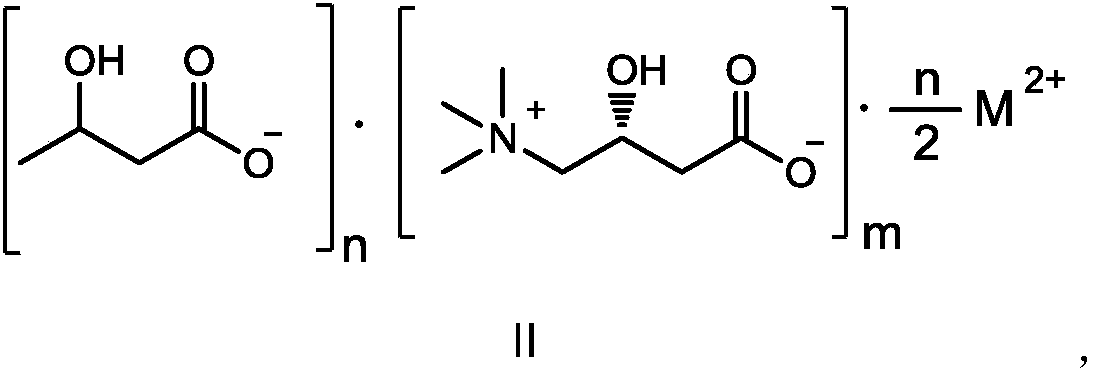

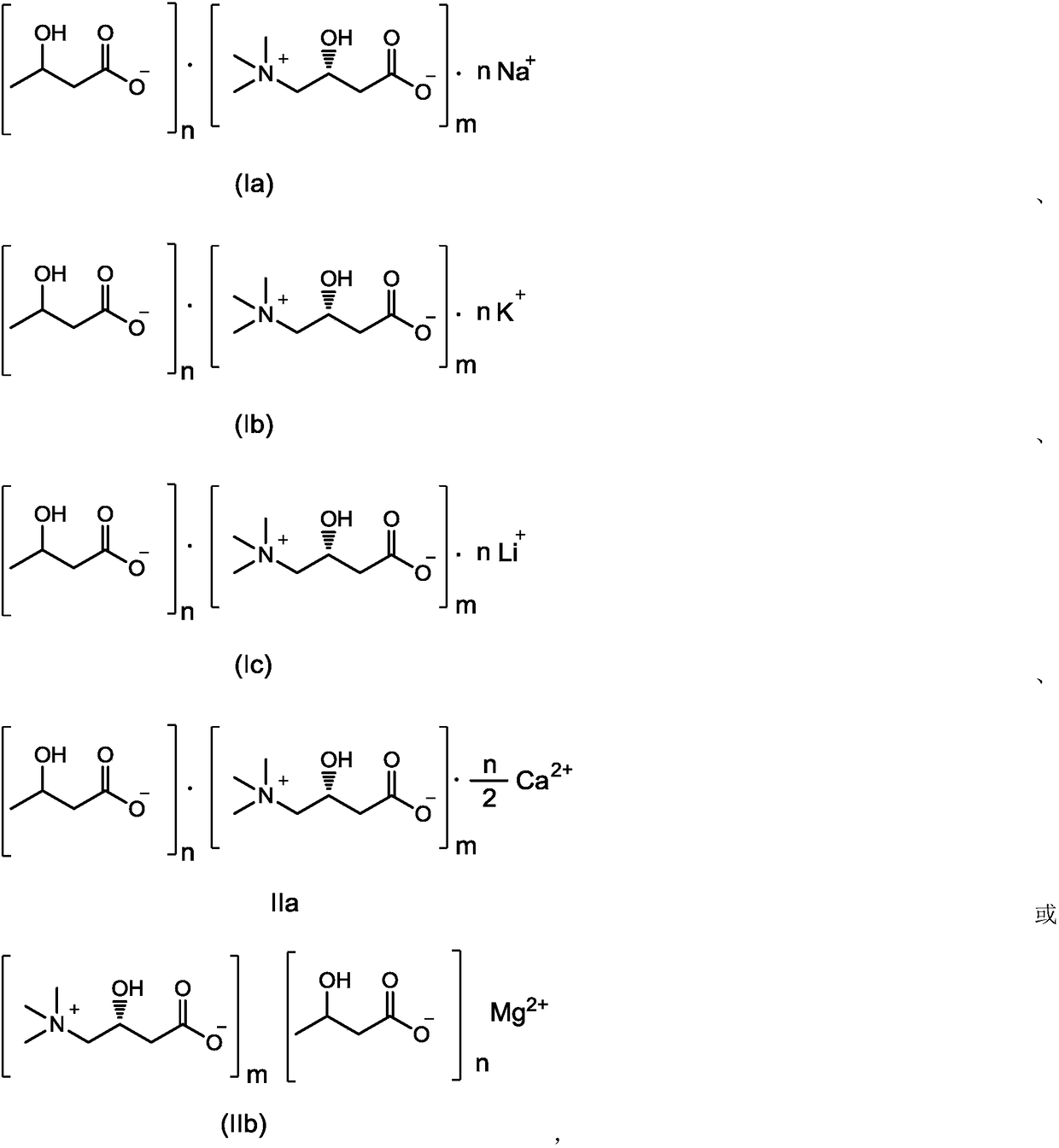

Composition containing L-carnitine and beta-hydroxybutyric acid compounds

PendingCN109394745AObvious advantagesQuick buildMetabolism disorderAntinoxious agentsBeta-Hydroxybutyric acidBioavailability

The invention provides a composition containing L-carnitine and a beta-hydroxybutyric acid compound, and specifically provides a composition containing the L-carnitine and at least one beta-hydroxybutyric acid compound. The beta-hydroxybutyric acid compound comprises beta-hydroxybutyrate, a beta-hydroxybutyric acid precursor or a combination thereof; and preferably, the L-carnitine and beta-hydroxybutyric acid amino acid exist in the composition in a form of intramolecular salt. The invention furthermore provides a preparation method of the L-carnitine-beta-hydroxybutyrate. The composition provided by the invention is high in stability, high in bioavailability and significant in weight loss effect and ketogenic effect; and the preparation method provided by the invention is easy and convenient to operate.

Owner:BRIGHTGENE BIO MEDICAL TECH (SUZHOU) CO LTD

Degradable ternary poly-beta-hydroxy butyrate and its prepn.

The present invention is characterized by that 70-92% of poly(beta-hydroxybutyrate), 4-20% of polyethylene glycol oxide, 3.5-20% of cellulose ester and 0.5-2% of adjuvant are uniformly mixed, placed into mould with 60-90 deg.C, then placed in an oil press, and the mould is heated to 160-195 deg.C to make hot-press formation, its pressure is 7-12 MPa, and the time is 20-40 min., then and mould is cooled to below 60 deg.C and demoulded so as to obtain the invented poly(beta-hydroxybutyrate) three-component blend. The melting temp. of said three-component blend is reduced, its toughness is improved and its complete degradability is also retained.

Owner:TIANJIN UNIV

Poly epsilon-caprolactone/poly (beta-hydroxybutyrate-valerate) blend membrane and preparation method thereof

The invention discloses a poly epsilon-caprolactone / poly (beta-hydroxybutyrate-valerate) blend membrane and a preparation method thereof, and belongs to the field of biodegradable materials. The blend membrane is a membrane produced by irradiation modification by an electron beam produced by gamma rays or an electron accelerator, the irradiation dose is 2-70 kGy, the membrane thickness is 20 to 200 microns, and taking the total membrane mass as 100%, the PCL (polycaprolactone) content is 20-80%, and the PHBV (poly hydroxyl butyrate valerate) content is 20-80%. The preparation method is as follows: respectively dissolving PCL and PHBV in solvents to obtain a solution 1 and a solution 2; (2) mixing the solution 1 and the 2 solution to obtain a mixed solution3; (3) casting a glass plate with the mixed solution3 to make the thickness uniform, forming a membrane by solvent evaporation, and obtaining a blend membrane by vacuum drying to a constant weight; and (4) performing irradiation on the blend membrane. According to the blend membrane, mechanical properties of the PCL and the PHBV are complemented, the brittleness of the PHBV is improved, the degradation performance is adjustable, and the method is simple in process and less in environmental pollution.

Owner:BEIJING RADIATION APPL RES CENT

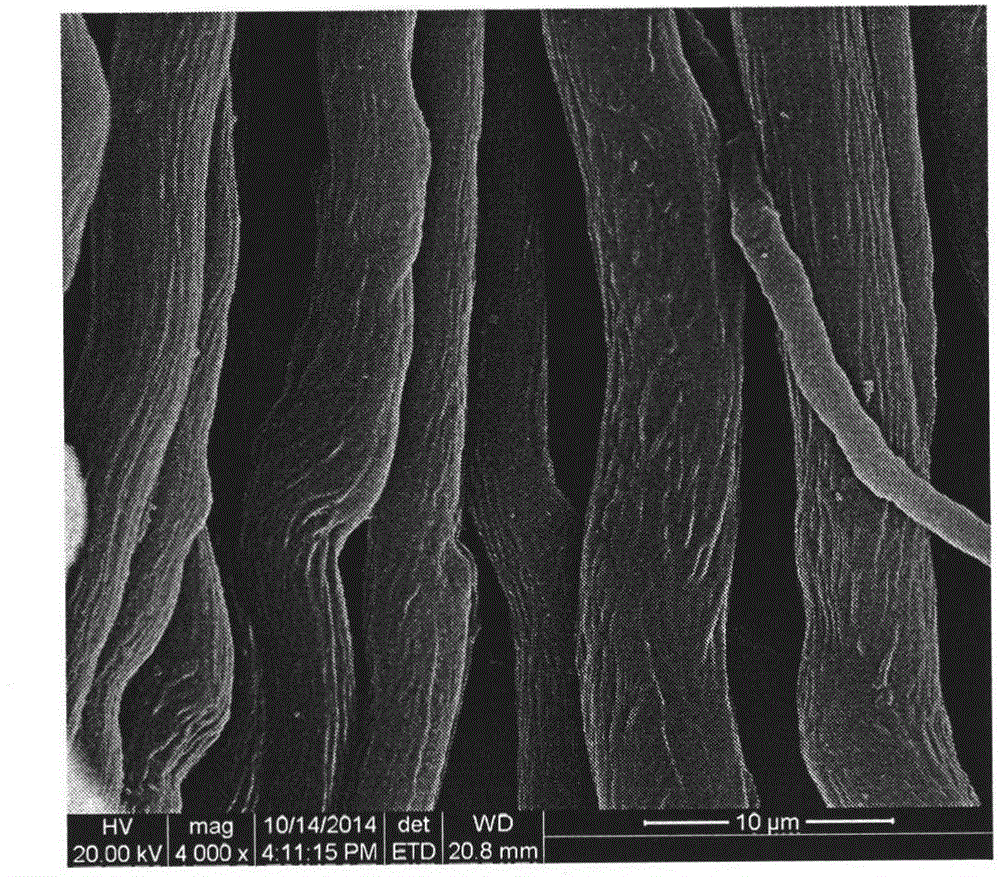

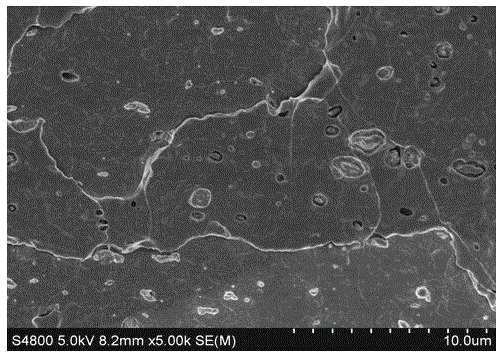

Method for preparing silicon-containing micron-fiber-toughened PHBV composite material

The invention discloses a method for preparing a silicon-containing micron-fiber-toughened PHBV composite material and belongs to the field of natural polymer material-toughened biodegradable plastics. The method comprises the following steps of dispersing a silicon-containing raw material in an aqueous sodium of sodium hydroxide with mass fraction of 10-35%, holding the temperature in a temperature range of 20-40 DEG C for 4-8 hours, diluting, filtering, adding 1-5% of a dispersant, carrying out low-pressure crushing by a homogenizing apparatus at a homogenizing pressure of 100-200bar, cycling for 6-15 times, separating and carrying out vacuum drying treatment to obtain silicon-containing micron-fiber; carrying out melt blending on silicon-containing micron-fiber, poly(beta-hydroxybutyrate-beta-hydroxyvalerate) (PHBV) at a mass ratio of (1:10)-(1:25), carrying out extrusion molding and granulating to prepare the silicon-containing micron-fiber-toughened PHBV composite material. By the method, when PHBV is toughened by virtue of the plant fiber in the prior art, the problems that the plant fiber needs to be prepared into nanoscale, a large amount of chemicals and power are consumed and the process is complex can be solved. According to the method for preparing the composite material, the agricultural residues can be utilized and thus the environment friendliness is achieved.

Owner:NANJING FORESTRY UNIV

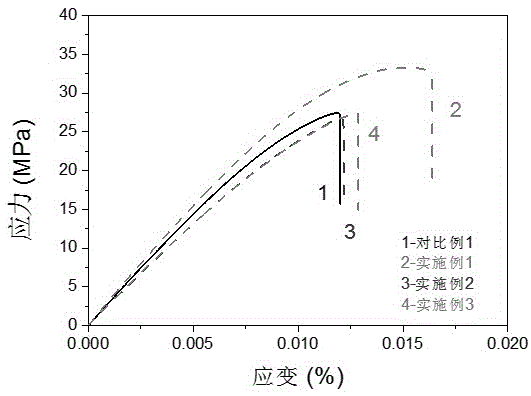

High-strength high-toughness fully-degradable bio-polyester composite material and preparation process thereof

ActiveCN110358280AIn situ polymerizationHomogeneous composite structureAntioxidantPolyethylene glycol

The invention relates to a high-strength high-toughness fully-degradable bio-polyester composite material and a preparation process thereof. The bio-polyester composite material is characterized by being prepared from aliphatic polycarbonate, lactic acid, poly(beta-hydroxybutyrate-co-beta hydroxyvalerate), four-arm polyethylene glycol propionaldehyde, chitosan and eight-arm polyethylene glycolpolyhedral oligomeric silsesquioxane, stannous octoate, stannous chloride, a melt enhancer and an antioxidant through reactive extrusion. The biomass composite material is simple in processing technology,has excellent strength and toughness, can realize full degradation, and can be applied to packaging and industrial fields requiring high strength and toughness.

Owner:深圳市广宇环保科技有限公司

Synthesis of degradable poly-beta-oxybate

The method for synthesizing completely-degradable plastics poly beta-hydroxybutyrate includes the folloiwng steps: adopting acetaldehyde as raw material to prepare beta-hydroxybutanal; oxidizing it to prepare beta-hydroxybutyric acid; esterifying it to prepare ethyl beta-hydroxybutyrate and polymerizing it to prepare poly beta-hydroxybutyrate. It is characterized by that preparation of beta-hydroxybutanal adopts benzene as solvent, sodium hydroxide as catalyst, its reaction temp. is 1-15 deg.C and the organic acid is used as neutralizing reagent, the preparation of beta-hydroxybutyric acid adopts ethyl acetate as solvent, cobalt acetate as catalyst, its reaction temp. is 40-100 deg.c and reaction pressure is 0.3-1.5 MPa, the preparation of ethyl ebeta-hydroxybutyrate adopts cresulsulfonic acid as catalyst and ethyl alcohol as solvent and polymerization preparation of beta-hydroxybutyrate uses isopropyl titanate as catalyst.

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI +1

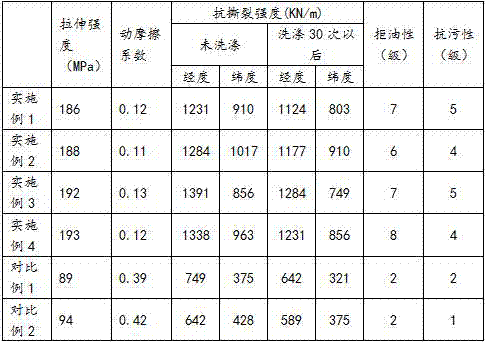

Antifouling and wear-resisting textile material and preparation method thereof

InactiveCN107326473AImprove wear resistanceAlso has anti-fouling propertiesConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsBeta-Hydroxybutyric acidBenzoyl peroxide

The invention discloses an antifouling and wear-resisting textile material and a preparation method thereof. The antifouling and wear-resisting textile material is prepared from the following raw materials in parts by weight: 10 to 25 parts of acrylonitrile fibers, 12 to 25 parts of carboxymethyl cellulose, 2 to 10 parts of nano-microcrystalline cellulose, 10 to 20 parts of bamboo charcoal fibers, 11 to 28 parts of diglycidyl ether, 3 to 5 parts of lauryl alcohol, 1 to 3 parts of bis-(phenyldimethyl siloxane)methylsilanol, 4 to 6 parts of beta-hydroxybutyrate, 1 to 3 parts of sodium thiosulfate pentahydrate, 8 to 14 parts of terephthaloyl chloride, 3 to 7 parts of fluorosilane, 1 to 4 parts of methyl L-pyroglutamate, 2 to 3 parts of benzoyl peroxide butyl acetate, 3 to 5 parts of 2,2'-(ethylenedioxy)dianiline, 1 to 2 parts of zinc diricinoleate, 1 to 2 parts of barium metaborate, 2 to 5 parts of an adhesive, 2 to 5 parts of a dispersant and 1 to 4 parts of a thermal stabilizer. The antifouling and wear-resisting textile material prepared by the preparation method has good wear-resisting performance and also has an antifouling property. Meanwhile, the invention further discloses the preparation method of the antifouling and wear-resisting textile material.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

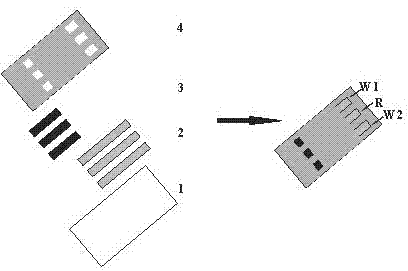

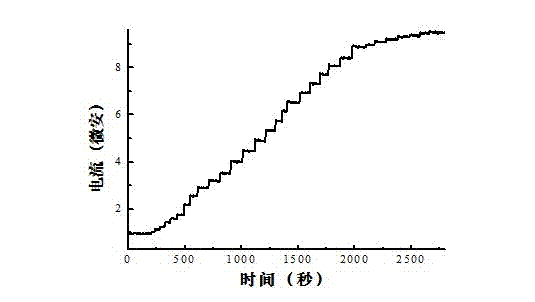

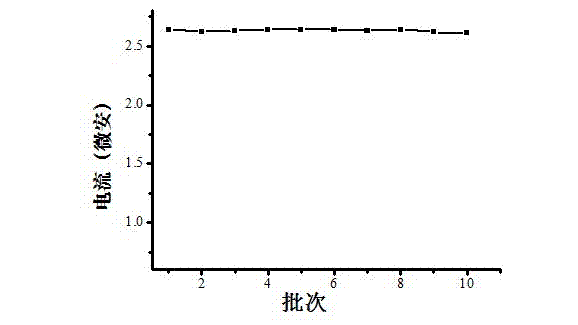

Preparation of silk-screen printing electrode for rapidly diagnosing diabetic ketoacidosis

InactiveCN102636539AQuick checkReal-time detectionMaterial analysis by electric/magnetic meansNitrocellulosePotassium ferricyanide

The invention relates to the field of rapidly diagnosing diabetic ketoacidosis. Electrochemical test paper is prepared by using a silk-screen printing process; and the content of beta-hydroxybutyrate in human blood is detected by current which is generated when beta-hydroxybutyrate is oxidized by an enzyme layer on the test paper, so as to judge whether the diabetic ketoacidosis exists or not. The enzyme layer is prepared from nitrocellulose, hydroxybutyrate dehydrogenase, glutaraldehyde, potassium ferricyanide, reduced coenzyme and chitosan. The preparation method of the enzyme layer comprises the following steps of: dissolving nitrocellulose, hydroxybutyrate dehydrogenase, potassium ferricyanide, reduced coenzyme and chitosan with a phosphoric buffered solution; then reacting with glutaraldehyde; dropwise adding a mixed solution on the test paper; and drying to finally obtain the enzyme layer of the electrochemical test paper for detecting the beta-hydroxybutyrate. The silk-screen printing electrode provided by the invention can be widely applied to rapid diagnosis of diabetic ketoacidosis.

Owner:湖南尔文水电建材有限公司

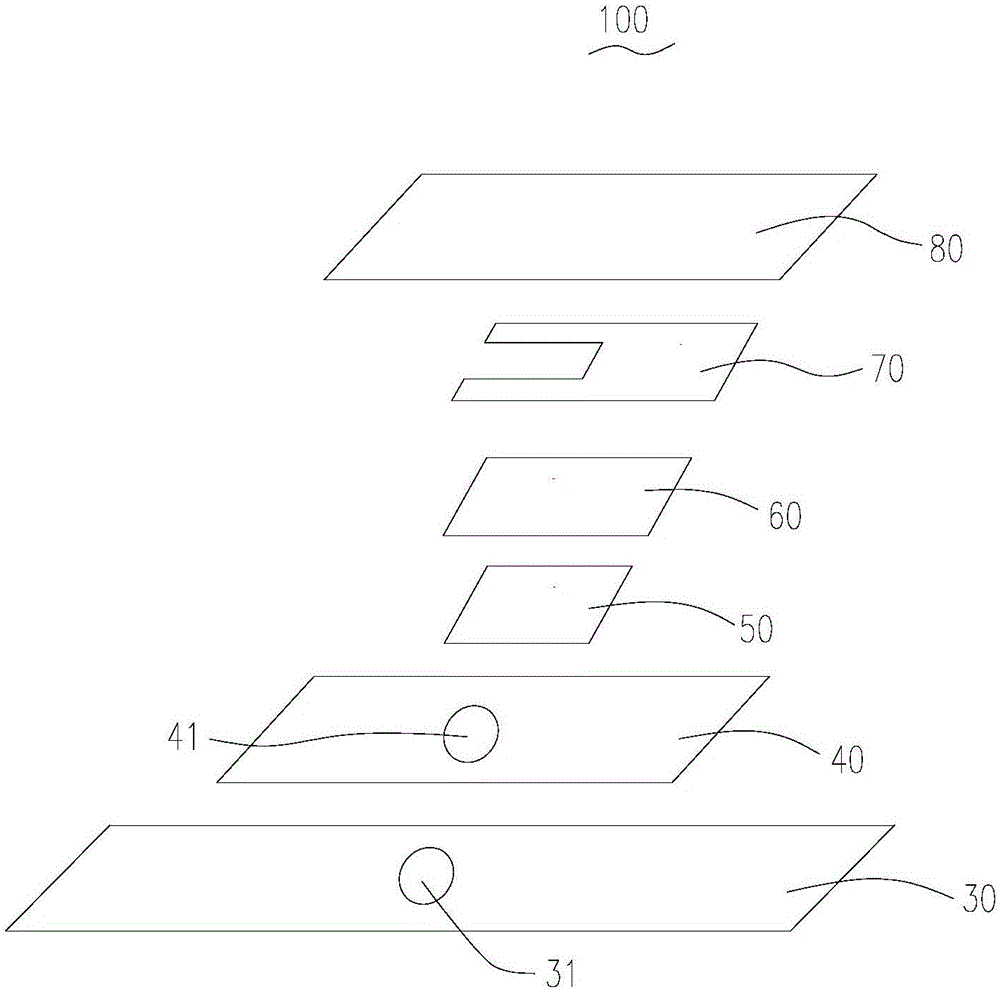

Detection reagent and test paper for beta-hydroxybutyrate

InactiveCN106706608AQuick checkAccurate detectionMaterial analysis by observing effect on chemical indicatorSiphonReaction layer

The invention discloses a detection reagent and test paper for beta-hydroxybutyrate. The detection reagent contains 3-5 KU / L of diaphorase, 9-13 KU / L of beta-hydroxybutyrate dehydrogenase, 1.2-2.5 KU / L of NAD and 0.6-1.0 KU / L of NBT. The detection reagent contains various specific enzymes for specific proportioning, thereby being capable of realizing rapid detection and more accurate detection. The test paper comprises a reaction base layer, a reaction layer, a blood filter layer and a hydrophilic layer which are stacked to form a siphon system, and rapid detection and more accurate detection are further guaranteed.

Owner:复星诊断科技(长沙)有限公司

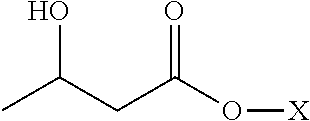

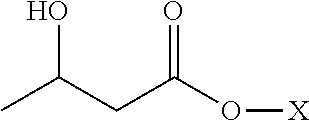

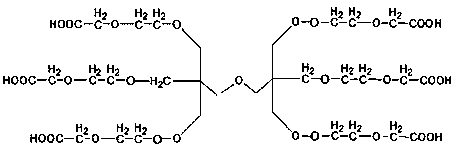

Medium chain fatty acid esters of beta-hydroxybutyrate and butanediol and compositions and methods for using same

ActiveUS20190359551A1Increase awarenessReduce expressionSenses disorderNervous disorderButanediolMedium chain fatty acid

Aspects of the present disclosure include fatty acid β-hydroxyester compounds (e.g., fatty acid esters of β-hydroxybutyrate), fatty acid esters of butanediol, and pharmaceutically acceptable salts thereof. Also provided are pharmaceutical compositions having one or more fatty acid β-hydroxyester compounds and / or one or more fatty acid esters of butanediol. Methods for treating a subject by administering one or more esters to the subject are also provided. Kits containing one or more of the subject esters are also described.

Owner:RGT UNIV OF CALIFORNIA +2

Food and drink composition for treating infantile autism and preparation method of composition

ActiveCN103876139AFast preparationEffective interventionHeavy metal active ingredientsNervous disorderInfantile autismVegetable oil

The invention discloses a food and drink composition. The food and drink composition is prepared from the following components based on specific content combination: edible vegetable oil, medium chain triglyceride, hydrolyzed small molecular protein powder, dietary fiber powder, nut meat, egg powder, polyols, sodium caseinate, mono and di-glycerin fatty acid ester, docosahexaenoic acid, arachidonic acid, taurine, phosphatidylcholine, phosphatidylserine, mineral substances, vitamins and the like, all components are interacted, the food and drink composition can promote metabolism in the body to produce acetoacetic acid, beta-hydroxybutyrate and acetone through dietary intervention to cause a series of biochemical influences on the brain under a condition of meeting primary nutrients requirement for the growth of autistic children, so as to achieve the effect of intervention treatment of infantile autism. The invention also discloses a preparation method and application of the food and drink composition.

Owner:广州友方生物科技有限公司

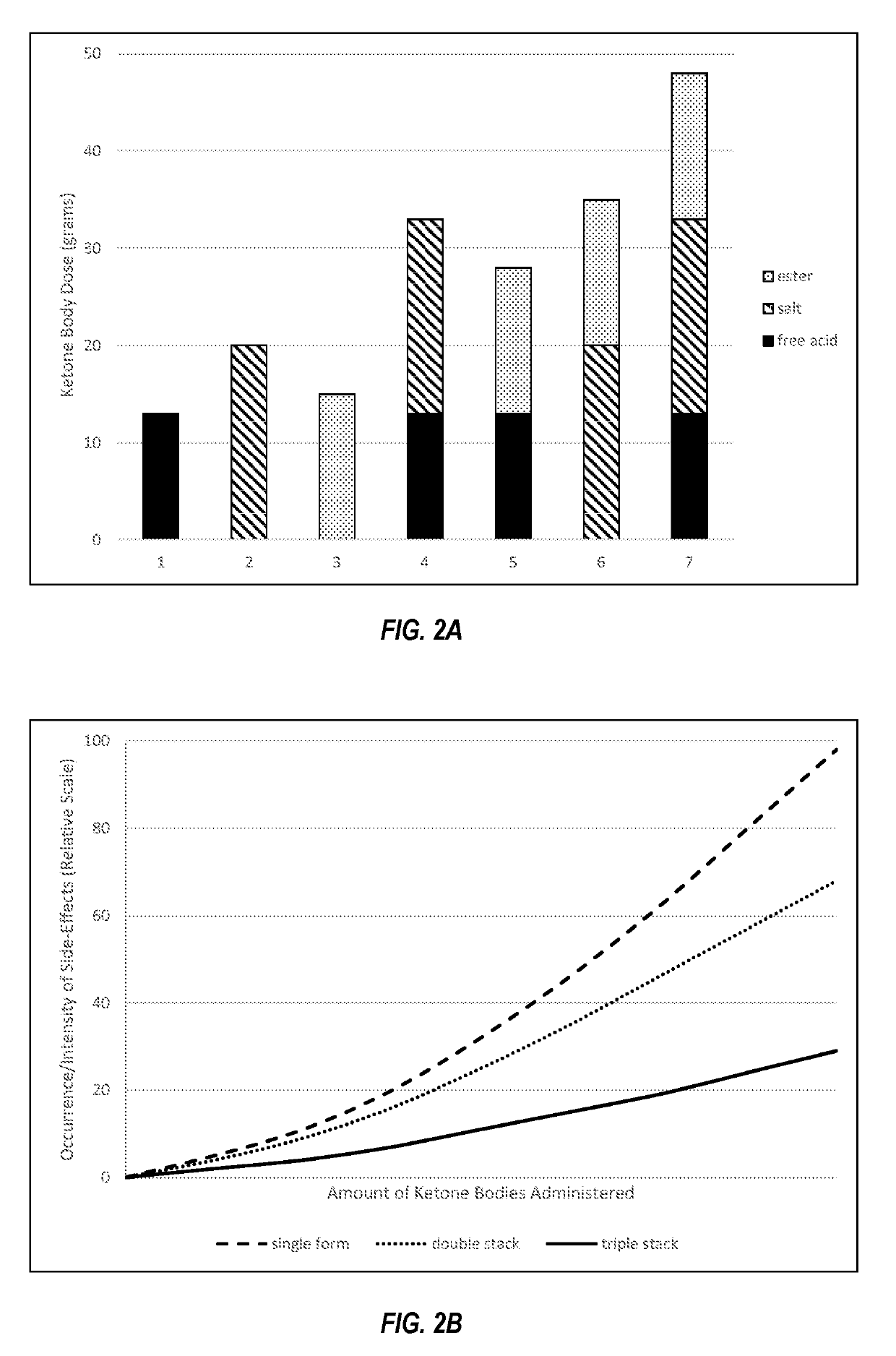

Compositions and methods for keto stacking with beta-hydroxybutyrate and acetoacetate

ActiveUS20190321309A1Promote and sustain ketosisLimit excess levelNervous disorderMetabolism disorderAcetoacetatesAcetic acid

Ketogenic compositions including beta-hydroxybutyrate (beta-hydroxybutyrate) and acetoacetate are formulated to induce, promote, or sustain ketosis in a mammal. The combined beta-hydroxybutyrate / acetoacetate compositions include an amount of acetoacetate that limits the reduction in available NAD+ in a subject without causing the formation of excess acetone in the bloodstream. In some aspects a composition for promoting and / or sustaining ketosis in a mammal contains a dietetically or pharmaceutically acceptable carrier and a beta-hydroxybutyrate / acetoacetate mixture of about 5% to about 45% acetoacetate by weight of the mixture and about 55% to about 95% beta-hydroxybutyrate by weight of the mixture.

Owner:AXCESS GLOBAL SCI LLC

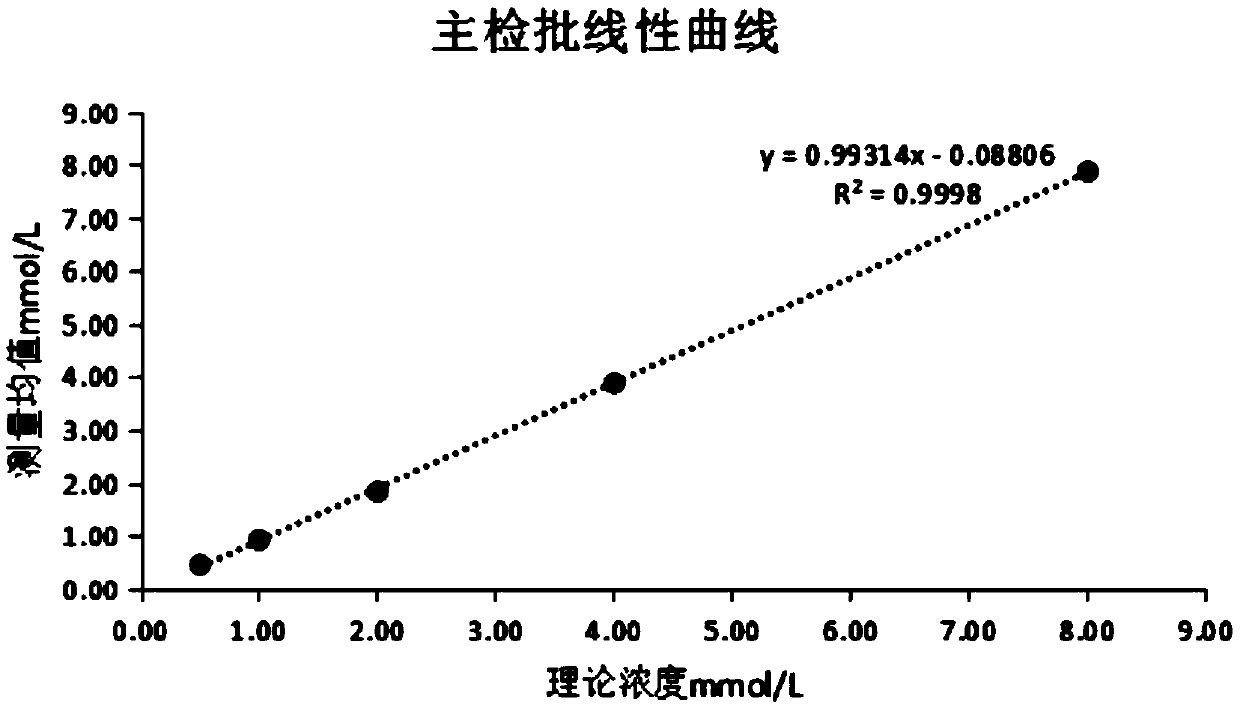

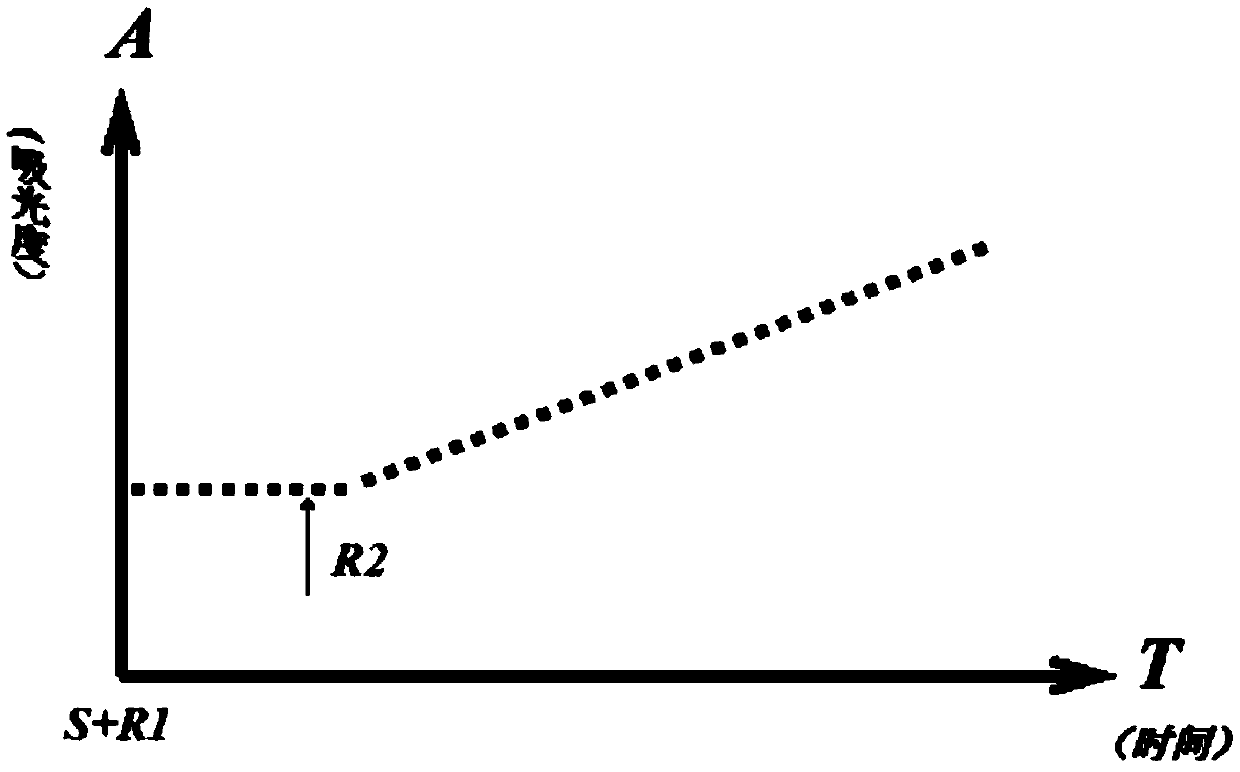

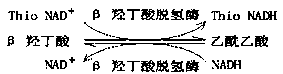

Determining method and determining kit for beta-hydroxybutyrate

InactiveCN105510255AHigh sensitivityLarge linear rangeColor/spectral properties measurementsAcetic acidLength wave

The invention relates to a cyclophorase determining method and a determining kit for beta-hydroxybutyrate. According to the method, beta-hydroxybutyrate is specifically oxidized by beta-hydroxybutyrate dehydrogenase and Thio-NAD<+>, and acetoacetic acid and Thio-NADH are produced; beta-hydroxybutyrate and NAD<+> are produced by acetoacetic acid in presence of beta-hydroxybutyrate dehydrogenase and NADH; reactions circulate, a large amount of Thio-NADH is produced, the content of beta-hydroxybutyrate can be calculated through determination of the absorbance increase amount rate of the produced Thio-NADH under the condition that the wavelength is 405 nm, the method has an amplification action on trace beta-hydroxybutyrate and has the advantages of high sensitivity, good stability, low cost and the like. The kit comprises NADH, beta-hydroxybutyrate dehydrogenase, Thio-NAD<+>, a buffer solution, a surfactant and a stabilizer. The method can be used for determining the content of beta-hydroxybutyrate through a biochemical analyzer.

Owner:江苏迈源生物科技有限公司

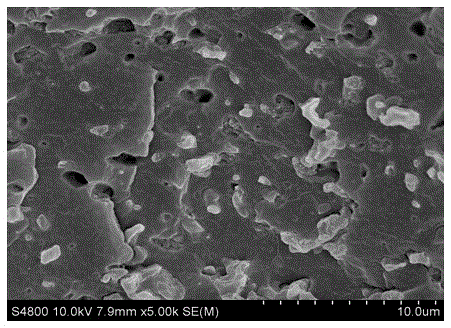

Preparing method for modified poly(beta-hydroxybutyrate) composite

The invention provides a preparing method for a modified poly(beta-hydroxybutyrate) composite and relates to the technical field of modification of poly(beta-hydroxybutyrate) and the technical field of degradable plastic.The preparing method comprises the steps that ethylene cellulose (EC) serves as a dispersing phase and is subjected to melt blending with poly(beta-hydroxybutyrate) (PHB) with a proper technology, EC is evenly dispersed in a biodegradable polyester PHB matrix, and a high-performance green polymer material is prepared.In a cellulose-based composite, EC influences the crystal habit and crystallization rate of the matrix polymer, even changes the compatibility and interfacial properties of incompatible blend systems and finally changes the ultimate performance of the matrix polymer, and thus the mechanical property, the crystallization degree and the crystal habit of the composite are controlled.

Owner:YANGZHOU UNIV

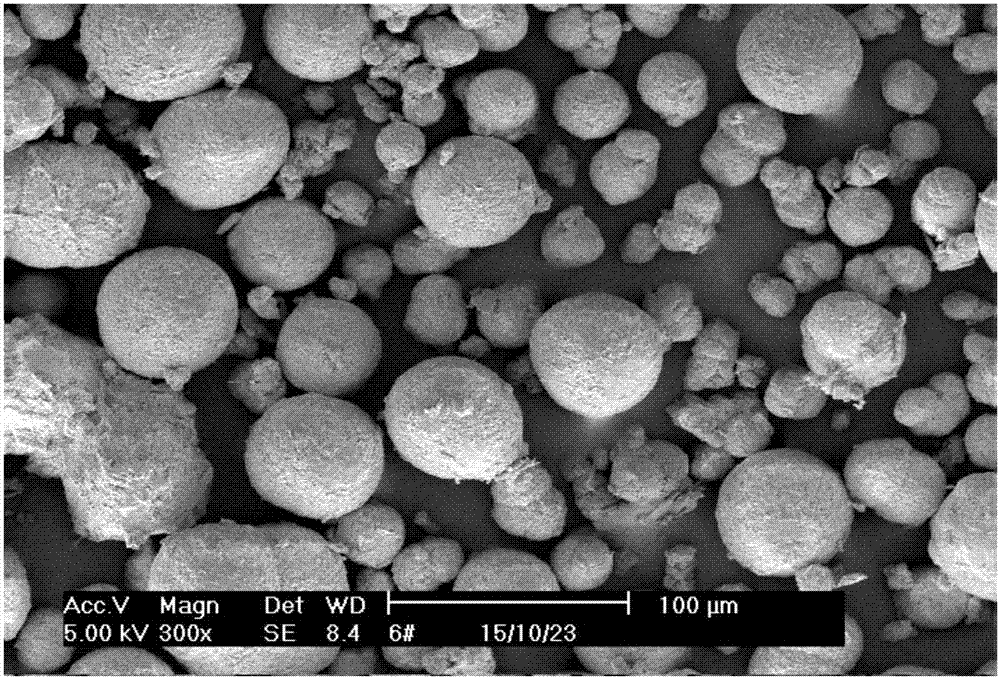

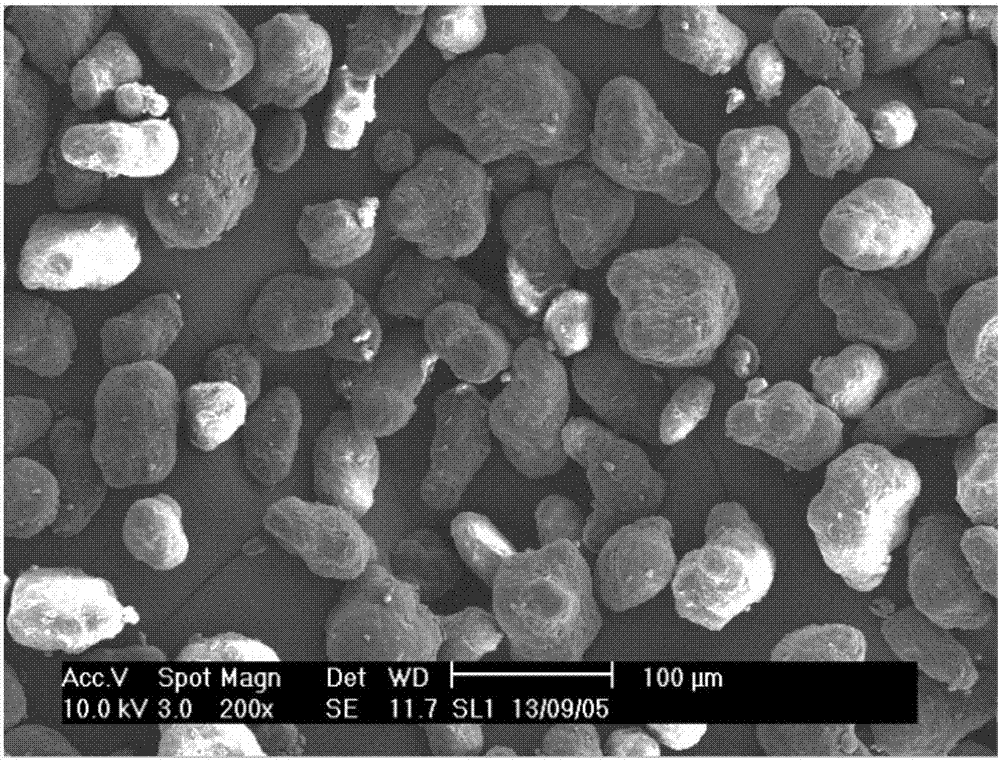

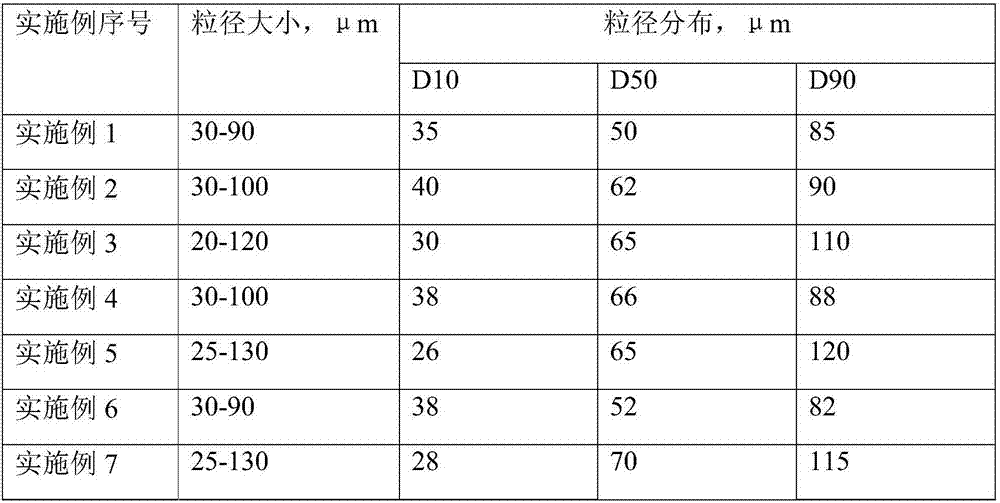

Beta-hydroxybutyrate and beta-hydroxyvalerate copolymer powder for selective laser sintering and preparation method thereof

The invention provides beta-hydroxybutyrate and beta-hydroxyvalerate copolymer powder for selective laser sintering and a preparation method thereof. According to the preparation method, a raw material of beta-hydroxybutyrate and beta-hydroxyvalerate resin powder having shape, property and the like especially suitable for selective laser sintering can be acquired by selecting proper solvent, especially specific temperature and pressure, and designing a proper heating and cooling mode.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com