Degradable food packaging film material and preparation technology thereof

A technology for food packaging film and preparation process, applied in sustainable packaging industry, sustainable manufacturing/processing, packaging, etc., can solve the problems of poor compatibility and poor mechanical properties of biomass film materials, and achieve uniform mechanical properties , Improve compatibility and ensure the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The preparation process of the degradable food packaging film material is as follows: the raw materials are put into a screw extruder to extrude and pelletize, and then put into a biaxial stretch film blowing machine to prepare a film;

[0064] The screw extruder is provided with two feed ports, the first feed port is located at the beginning of the feed section of the extrusion screw, and the second feed port is located at 5 / 6 of the feed section of the extrusion screw.

[0065] (1) The processing characteristics of the extrusion section are as follows:

[0066] 1) All raw materials are divided into two parts, which are fed in different feed ports;

[0067] The first part of the materials includes:

[0068] 75% polybutylene succinate, 65% carboxy-terminated polylactic acid, 72% carboxymethyl chitosan, 52% melt enhancer, all six-arm polyethylene glycol carboxyl , Antioxidant;

[0069] The material is fully dried and mixed evenly at high speed before feeding;

[0070...

specific Embodiment 2

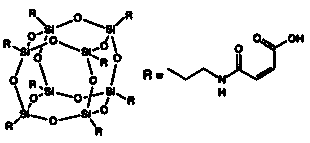

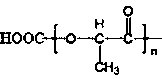

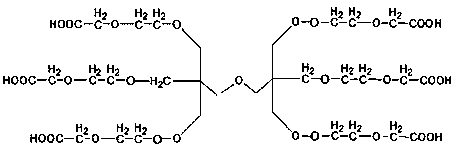

[0081] A degradable food packaging film material and its preparation process, the material is polybutylene succinate, lactic acid, carboxyl-terminated polylactic acid, six-arm polyethylene glycol carboxyl, carboxymethyl chitosan, eight-arm maleic anhydride Cage polysilsesquioxane, melt reinforcing agent, antioxidant, and stannous chloride are prepared as raw materials through reactive extrusion and then biaxially stretched to form a film. The ratio of each raw material component by mass is as follows:

[0082] Polybutylene succinate 15 parts

[0083] Lactic acid 25.5 parts

[0084] Carboxy-terminated polylactic acid 8.5 parts

[0085] Six-arm polyethylene glycol carboxyl 4.5 parts

[0086] Carboxymethyl chitosan 10.5 parts

[0087] Eight-arm maleic anhydride cage polysilsesquioxane 2.2 parts

[0088] Tin protochloride 0.1 parts

[0089] Melt enhancer 4.5 parts

[0090] Antioxidant 1.2 parts.

[0091] The molecular weight of the polybutylene succinate is between 200000-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal stretch temperature | aaaaa | aaaaa |

| Transverse stretch temperature | aaaaa | aaaaa |

| Longitudinal stretch temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com