Preparing method for modified poly(beta-hydroxybutyrate) composite

A technology of hydroxybutyrate and composite materials, which is applied in the field of polymer modification and degradable plastics, which can solve the problems of restricting the use of PHB, low melt strength, and restricting the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

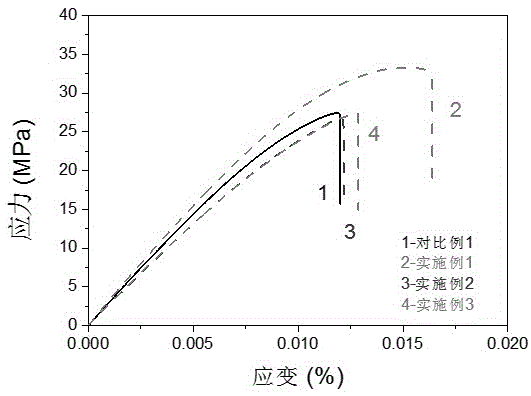

Examples

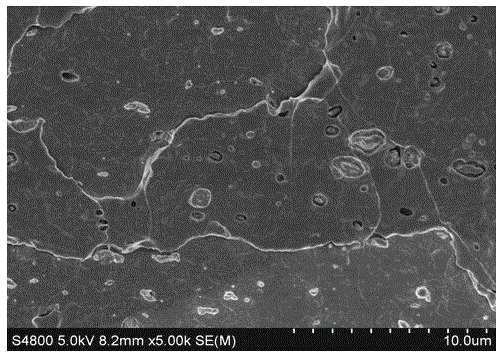

Embodiment 1

[0020] 1. First place ethyl cellulose (EC) and poly(β-hydroxybutyrate) (PHB) in a vacuum drying oven, dry at 60°C for 24 hours, cool to room temperature, and make the mass ratio 1:99 The EC and PHB were placed in an internal mixer, the temperature of the internal mixer was controlled at 180 °C, the rotor speed was 90 rpm, and after melt blending for 5 minutes, the poly(β-hydroxybutyrate) modified by ethyl cellulose was obtained. composite material.

[0021] 2. Use a micro-injection molding machine to inject the output into standard dumbbell-shaped (32mm×4mm×2mm) and standard rectangular (80mm×10mm×4mm) specimens for testing tensile and impact properties. The injection process is: barrel temperature 180°C, mold temperature 30°C, injection pressure 600bar, holding pressure 500bar.

Embodiment 2

[0023] 1. First place EC and PHB in a vacuum drying oven, dry at 60°C for 24 hours, cool to room temperature, put EC and PHB with a mass ratio of 5:95 in an internal mixer, and control the temperature of the internal mixer to 180° C., the rotor speed was 90 rpm, and after melt blending for 5 minutes, a composite material of ethyl cellulose-modified poly(β-hydroxybutyrate) was obtained.

[0024] 2. Use a micro-injection molding machine to inject the output into standard dumbbell-shaped (32mm×4mm×2mm) and standard rectangular (80mm×10mm×4mm) specimens for testing tensile and impact properties. The injection process is: barrel temperature 180°C, mold temperature 30°C, injection pressure 600bar, holding pressure 500bar.

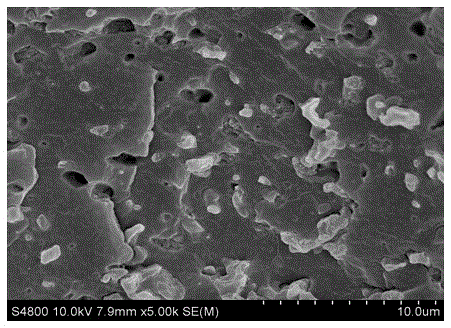

Embodiment 3

[0026] 1. First place EC and PHB in a vacuum drying oven, dry at 60°C for 24 hours, cool to room temperature, put EC and PHB with a mass ratio of 20:80 in an internal mixer, and control the temperature of the internal mixer to 180° C., the rotor speed was 90 rpm, and after melt blending for 5 minutes, a composite material of ethyl cellulose-modified poly(β-hydroxybutyrate) was obtained.

[0027] 2. Use a micro-injection molding machine to inject the output into standard dumbbell-shaped (32mm×4mm×2mm) and standard rectangular (80mm×10mm×4mm) specimens for testing tensile and impact properties. The injection process is: barrel temperature 180°C, mold temperature 30°C, injection pressure 600bar, holding pressure 500bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com