Degradable ternary poly-beta-hydroxy butyrate and its prepn.

A hydroxybutyrate and blend technology, applied in the field of plastic processing and molding, can solve the problems of easy re-brittleness, high price, complicated process, etc., and achieve the effects of obvious sustainable development, wide application range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

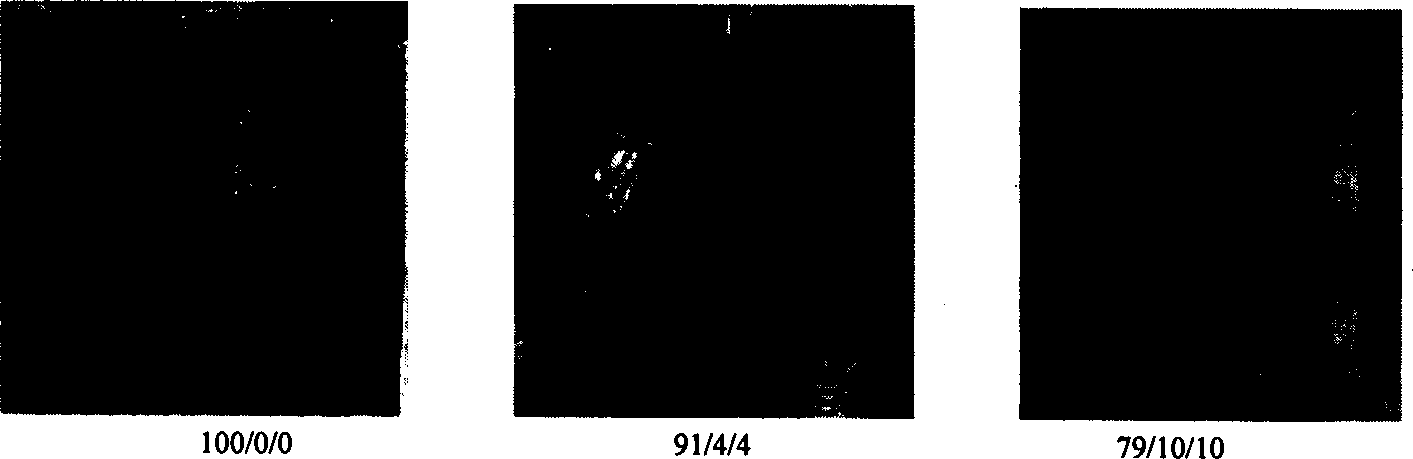

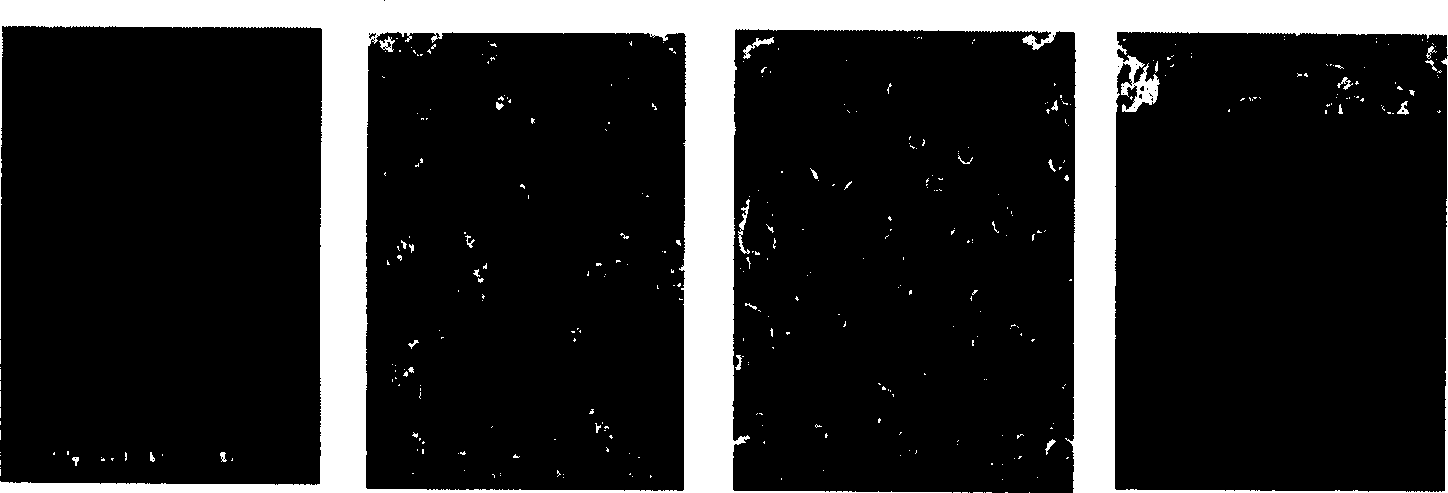

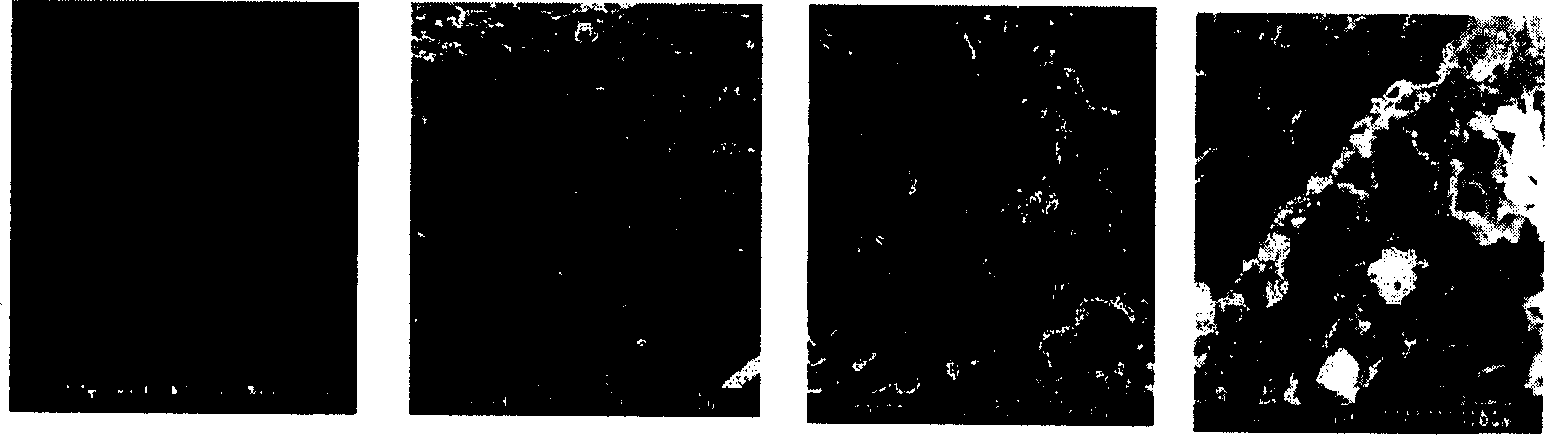

[0012] The specific embodiment 1, PHB / PEO / CAB ternary blend composition ratio (percentage by weight) 91 grams of poly(β-hydroxybutyrate), 4 grams of polyethylene oxide, 4 grams of cellulose acetate butyrate, auxiliary agent (nucleating agent, plasticizer, etc.) 1 g. 2. PHB / PEO / CAB ternary blend composition ratio (percentage by weight) 79 grams of poly(β-hydroxybutyrate), 10 grams of polyethylene oxide, 10 grams of cellulose acetate butyrate, auxiliary agent (nucleating agent, plasticizer, etc.) 1 g. 3. PHB / PEO / CAB ternary blend composition ratio (percentage by weight) 70 grams of poly(β-hydroxybutyrate), 10 grams of polyethylene oxide, 19 grams of cellulose acetate butyrate, auxiliary agent (nucleating agent, plasticizer, etc.) 1 g. 4. PHB / PEO / CAB ternary blend composition ratio (percentage by weight) 70 grams of poly(β-hydroxybutyrate), 19 grams of polyethylene oxide, 10 grams of cellulose acetate butyrate, auxiliary agent (nucleating agent, plastici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com