Production method of sodium thiosulfate pentahydrate

A technology of sodium thiosulfate pentahydrate and its production method, applied in the directions of thiosulfate/dithionite/polythionate, chemical instruments and methods, alkali metal sulfite/sulfite, etc., capable of Solve the problems of many elements in the slag, high difficulty in producing qualified products, and complex components, so as to achieve the effects of reducing production costs, high production efficiency, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

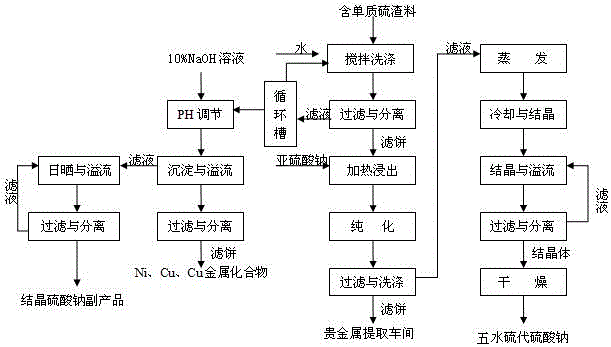

Method used

Image

Examples

Embodiment 1

[0024] Slag containing elemental sulfur: S 66.25%, Na 2 SO4 12%, Ag 50.9g / t, Au 46.38g / t, Pd 23.46g / t, Pt31.82g / t. Put the slag material containing elemental sulfur in a beaker with a stirring device, add water to the beaker, the amount of water added is 10 times that of the slag material containing elemental sulfur on a dry basis, after stirring for 30 minutes, filter and separate to obtain the main components: For filter cake A and filtrate A of elemental sulfur, continue to add sodium sulfite and water into the beaker containing filter cake A, the amount of sodium sulfite added is 1.15 times of the theoretical calculation amount, and the amount of water added is 17 times the weight of the slag material containing elemental sulfur , put the mixed solution beaker in a water bath, heat and stir the sodium sulfite and elemental sulfur at 80°C for 3.5 hours, and detect that the pH of the solution is 7-8 and the solution is colorless and transparent. After solid-liquid separation...

Embodiment 2

[0026] The composition of the slag material containing elemental sulfur is the same as in Example 1. Put the slag material containing elemental sulfur in a beaker with a stirring device, add water to the beaker, the amount of water added is 10 times that of the slag material containing elemental sulfur on a dry basis, after stirring for 30 minutes, filter and separate to obtain the main components: Filter cake A and filtrate A of elemental sulfur slag material, continue to add sodium sulfite and water in the beaker that filter cake A is housed, the addition of sodium sulfite is 1.2 times of theoretically calculated amount, and the addition of water is 1 / 2 of the weight of elemental sulfur slag material. 20 times, put the mixed solution beaker in a water bath, heat and stir at 80°C for 3.5 hours, detect that the pH of the solution is > 8 and the solution is white and translucent, continue to add elemental sulfur-containing slag, and adjust the pH of the solution 7-8 and the sol...

Embodiment 3

[0028] The composition of the slag material containing elemental sulfur is the same as in Example 1. Put the slag material containing elemental sulfur in a beaker with a stirring device, add water to the beaker, the amount of water added is 10 times that of the slag material containing elemental sulfur on a dry basis, after stirring for 30 minutes, filter and separate to obtain the main components: For filter cake A and filtrate A of elemental sulfur, continue to add sodium sulfite and water into the beaker containing filter cake A, the amount of sodium sulfite added is 1.1 times of the theoretical calculation amount, and the amount of water added is 15 times the weight of the slag material containing elemental sulfur , put the mixed solution beaker in a water bath, heat and stir for leaching at 80°C for 3.5 hours, detect that the pH of the solution is <7 and the solution is light yellow and transparent, continue to add sodium sulfite to adjust the pH of the solution to 7-8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com