Sewage treatment formula and preparation method thereof

A sewage treatment and formulation technology, applied in water/sludge/sewage treatment, special treatment targets, chemical instruments and methods, etc., can solve problems such as long cleaning time, high volatility, and affecting production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

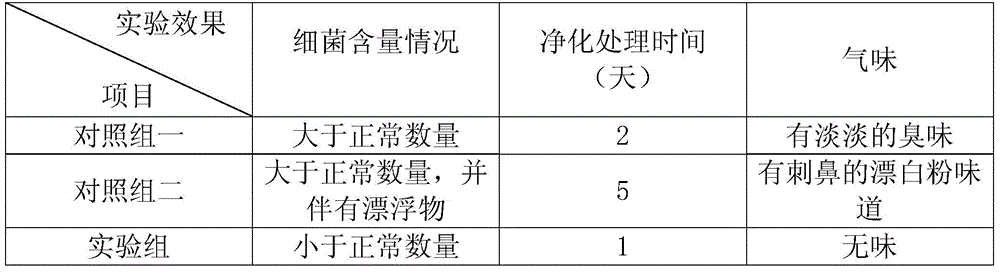

Examples

Embodiment 1

[0020] A sewage treatment formula made of the following materials in parts by weight: 85 parts of polyacrylamide, 30 parts of chlorine dioxide, 35 parts of sodium thiosulfate pentahydrate, 40 parts of dilute hydrochloric acid, and 50 parts of polyaluminum chloride 35 parts of inorganic polyphosphate, 20 parts of sodium hypochlorite, 100 parts of cohesive soil, 80 parts of talcum powder, 40 parts of activated carbon fiber, 45 parts of nano-magnetic powder, 20 parts of polyvinyl alcohol, 10 parts of triethylenediamine and magnesium silicate 30 servings.

[0021] A preparation method for sewage treatment formula, comprising the following steps:

[0022] 1) Take 100 parts of cohesive soil and 80 parts of talcum powder, dry and grind to pulverize, filter it through a 50-mesh sieve, and prepare the mixed powder for subsequent use;

[0023] 2) Add 40 parts of dilute hydrochloric acid to the mixed powder prepared in step 1), and after making it uniform, pile it up for 10 hours to obt...

Embodiment 2

[0031] A sewage treatment formula made of the following materials in parts by weight: 55 parts of polyacrylamide, 30 parts of chlorine dioxide, 35 parts of sodium thiosulfate pentahydrate, 40 parts of dilute hydrochloric acid, and 50 parts of polyaluminum chloride 35 parts of inorganic polyphosphate, 20 parts of sodium hypochlorite, 100 parts of cohesive soil, 80 parts of talcum powder, 40 parts of activated carbon fiber, 45 parts of nano-magnetic powder, 20 parts of polyvinyl alcohol, 10 parts of triethylenediamine and magnesium silicate 30 servings.

[0032] A preparation method for sewage treatment formula, comprising the following steps:

[0033] 1) Take 120 parts of cohesive soil and 110 parts of talc powder after drying and grind to pulverize, filter it through a 50-mesh sieve, and prepare the mixed powder for subsequent use;

[0034] 2) Add 60 parts of dilute hydrochloric acid to the mixed powder prepared in step 1), and after it is uniform, pile it up for 10 hours to ...

Embodiment 3

[0042] A sewage treatment formula made of the following materials in parts by weight: 70 parts of polyacrylamide, 42 parts of chlorine dioxide, 50 parts of sodium thiosulfate pentahydrate, 50 parts of dilute hydrochloric acid, and 65 parts of polyaluminum chloride 45 parts of inorganic polyphosphate, 37 parts of sodium hypochlorite, 110 parts of cohesive soil, 95 parts of talcum powder, 50 parts of activated carbon fiber, 55 parts of nano magnetic powder, 30 parts of polyvinyl alcohol, 20 parts of triethylenediamine and magnesium silicate 45 servings.

[0043] A preparation method for sewage treatment formula, comprising the following steps:

[0044] 1) Take 110 parts of cohesive soil and 95 parts of talc powder after drying and grind to pulverize, filter it through a 50-mesh sieve, and prepare the mixed powder for subsequent use;

[0045] 2) Add 50 parts of dilute hydrochloric acid to the mixed powder prepared in step 1), and after making it uniform, pile it up for 10 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com