Preparation method of metallic oxide/conducting polymer dually-modified sulfur composite anode material

A composite positive electrode material and conductive polymer technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as electrode structure damage, achieve the effects of improving wettability, broad application prospects, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

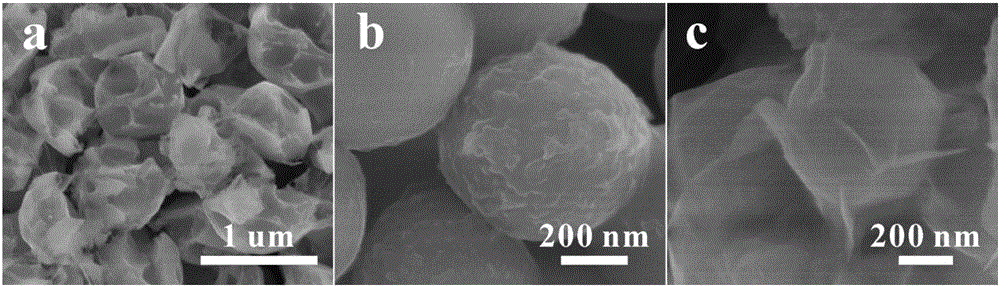

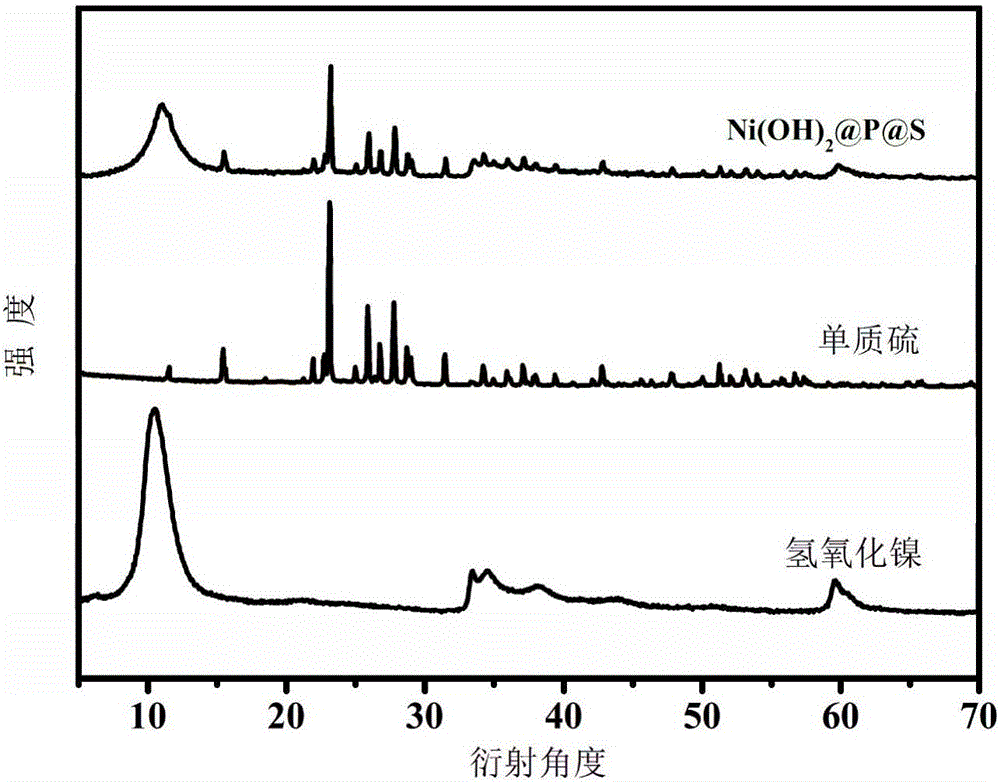

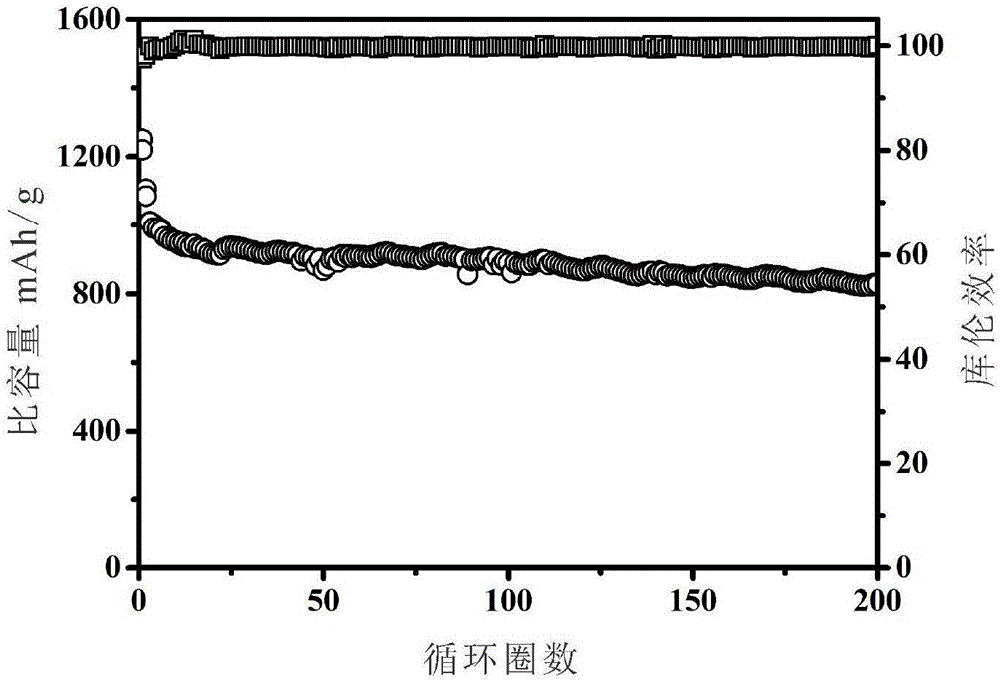

[0028]In the first step, first add 5g sodium thiosulfate pentahydrate, 0.1g polyvinylpyrrolidone and 7g hydrochloric acid (mass concentration is 37%, the same below) to 100mL deionized water, stir and mix at medium speed for 4 hours by an electromagnetic stirrer. After the reaction, the product was centrifuged and washed (8000 rpm) three times with deionized water and absolute ethanol, and the precipitate obtained by centrifugation was placed in a vacuum drying oven and dried at 60° C. for 36 hours to obtain hollow nano-sulfur particles. Gather spares.

[0029] In the second step, the hollow nano-sulfur particles obtained in the previous step were dispersed into 200 mL of deionized water, and ultrasonically dispersed for 30 minutes to form a uniform solution. Then, 0.122 g of aniline, 0.25 g of hydrochloric acid and 0.2 g of ammonium persulfate were sequentially added to the solution, and stirred and mixed at a medium speed by a magnetic stirrer for 12 hours. After the reacti...

Embodiment 2

[0033] In the first step, 5 g of sodium thiosulfate pentahydrate, 0.1 g of polyvinylpyrrolidone, and 3 g of hydrochloric acid were first added to 100 mL of deionized water, and stirred and mixed at a medium speed by an electromagnetic stirrer for 1 hour. After the reaction, the product was centrifuged and washed (5000 rpm) three times with deionized water and absolute ethanol, and the precipitate obtained by centrifugation was placed in a vacuum drying oven and dried at 40°C for 24 hours to obtain hollow nano-sulfur particles, collected spare.

[0034] In the second step, the hollow nano-sulfur particles obtained in the previous step were dispersed into 200 mL of deionized water, and ultrasonicated for 10 minutes to form a uniform solution. Then, 0.122 g of aniline, 0.08 g of hydrochloric acid and 0.2 g of ammonium persulfate were successively added to the solution, and stirred and mixed at a medium speed by a magnetic stirrer for 18 hours. After the reaction, the product was...

Embodiment 3

[0038] In the first step, 5 g of sodium thiosulfate pentahydrate, 0.1 g of polyvinylpyrrolidone, and 10 g of hydrochloric acid were first added to 100 mL of deionized water, and stirred and mixed at a medium speed by an electromagnetic stirrer for 8 hours. After the reaction, the product was centrifuged and washed (6000 rpm) three times with deionized water and absolute ethanol, and the precipitate obtained by centrifugation was placed in a vacuum drying oven and dried at 80°C for 12 hours to obtain hollow nano-sulfur particles, collected spare.

[0039] In the second step, the hollow nano-sulfur particles obtained in the previous step were dispersed into 200 mL of deionized water, and ultrasonicated for 60 minutes to form a uniform solution. Then, 0.122 g of aniline, 0.48 g of hydrochloric acid and 0.2 g of ammonium persulfate were successively added to the solution, and stirred and mixed at a medium speed by a magnetic stirrer for 6 hours. After the reaction, the product wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com