Amino acid compound leaf fertilizer and preparation method thereof

An amino acid and foliar fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of low element utilization rate, unstable effect, low effective content, etc., and achieve good fruit quality, increased resistance, and effective results. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

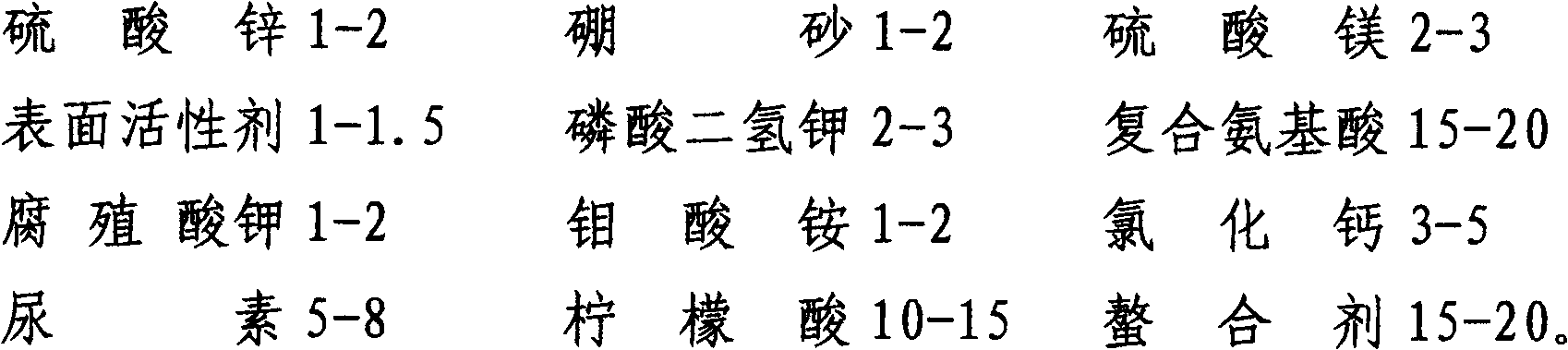

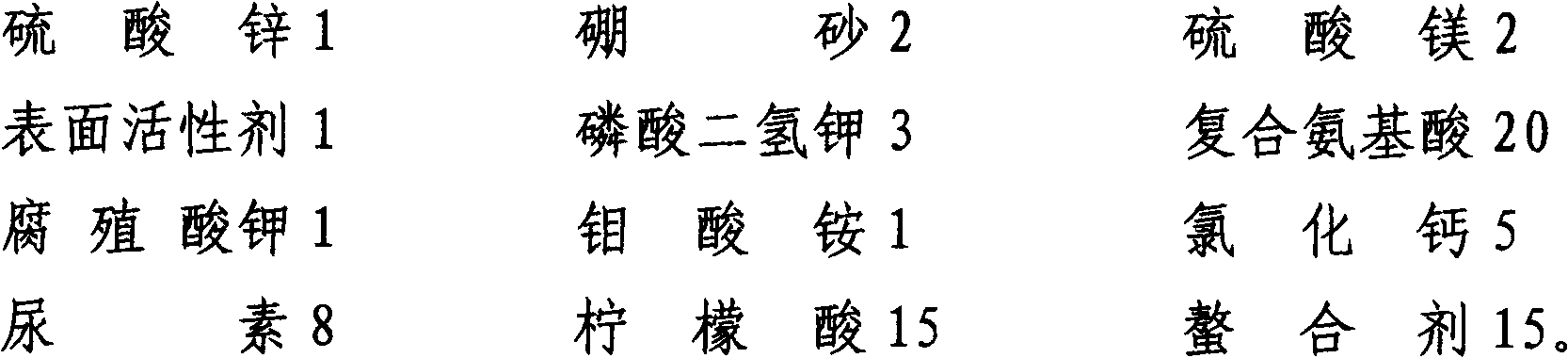

Embodiment 1

[0028] (1), weigh 1 part of zinc sulfate, 2 parts of borax, 2 parts of magnesium sulfate, 1 part of surfactant, 3 parts of potassium dihydrogen phosphate, and compound amino acid (this example uses the amino acid extracted from soybean protein) according to the weight ratio. , can also adopt other amino acids; hereinafter the same) 20 parts, 1 part of potassium humate, 1 part of ammonium molybdate, 5 parts of calcium chloride, 8 parts of urea, 15 parts of citric acid, 15 parts of chelating agent, spare;

[0029] (2) Add 5 parts of calcium chloride, 1 part of zinc sulfate, 2 parts of borax and 2 parts of magnesium sulfate into 22 parts of water successively, stir and dissolve, and adjust the pH value to neutral with dilute sulfuric acid solution to make the solution clear and transparent , made into nutrient solution, for later use;

[0030] (3), with 15 parts of standby chelating agents, 15 parts of citric acid, 20 parts of compound amino acids, add 22 parts of water, stir and...

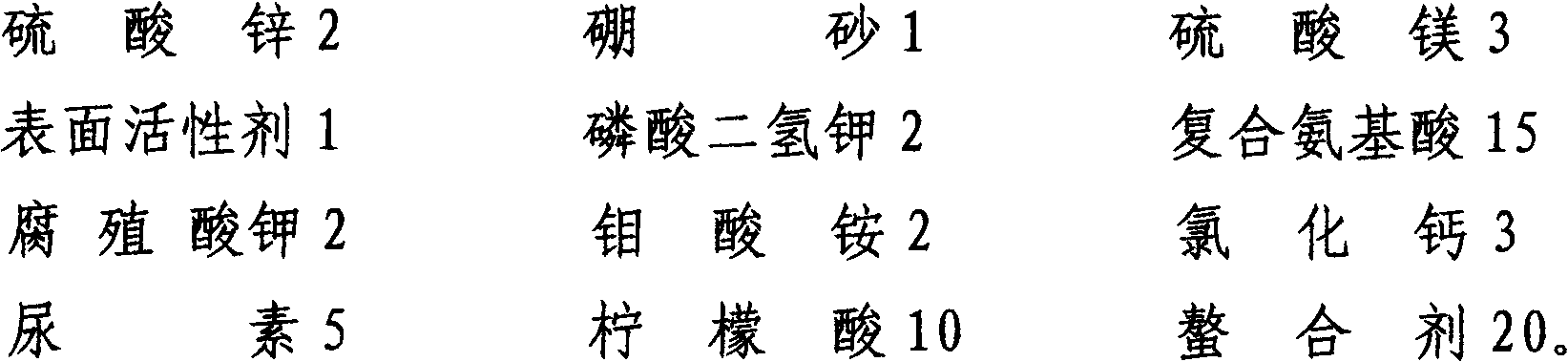

Embodiment 2

[0042] (1), take by weight 2 parts of zinc sulfate, 1 part of borax, 3 parts of magnesium sulfate, 1 part of surfactant, 2 parts of potassium dihydrogen phosphate, 15 parts of compound amino acids, 2 parts of potassium humate, 2 parts of ammonium molybdate, 3 parts of calcium chloride, 5 parts of urea, 10 parts of citric acid, 20 parts of chelating agent, spare;

[0043] Its preparation method and use method etc. are the same as embodiment one.

Embodiment 3

[0045] (1), take by weight 1 part of zinc sulfate, 1 part of borax, 2 parts of magnesium sulfate, 1.5 parts of surfactant, 2 parts of potassium dihydrogen phosphate, 18 parts of compound amino acids, 2 parts of potassium humate, 1 part of ammonium molybdate, 4 parts of calcium chloride, 6 parts of urea, 12 parts of citric acid, 18 parts of chelating agent, spare;

[0046] Its preparation method and use method etc. are the same as embodiment one.

[0047] The amino acid compound foliar fertilizer of the invention can be widely used as crops such as tobacco, citrus, vegetables, melons and fruits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com