Method for preparing microcrystalline glass by using blast furnace slag

A technology for glass-ceramic and blast furnace slag, which is applied in the field of preparation of glass-ceramic materials, can solve the problems of low utilization rate of slag, high cost, complicated preparation process, etc., and achieve the effects of saving resources, reducing pollution and avoiding complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) The composition of the slag used is: SiO 2 33wt%, Al 2 o 3 is 13wt%, CaO is 38wt%, and MgO is 9wt%. The glass-ceramic raw material composition is 95wt% slag and 5wt% feldspar.

[0019] (2) The blast furnace slag raw material is ball milled for 48 hours, passed through a 200 mesh sieve and equipped with feldspar additive, and the fineness of the additive is 200 mesh;

[0020] (3) Ball milling and mixing for 10 hours to make a slurry, wherein the ratio of material, balls, and water is 1:1.5:1.5, dry the slurry at 60°C until the water content is ≤5%, add glycerin to granulate, and press to form under 20MPa;

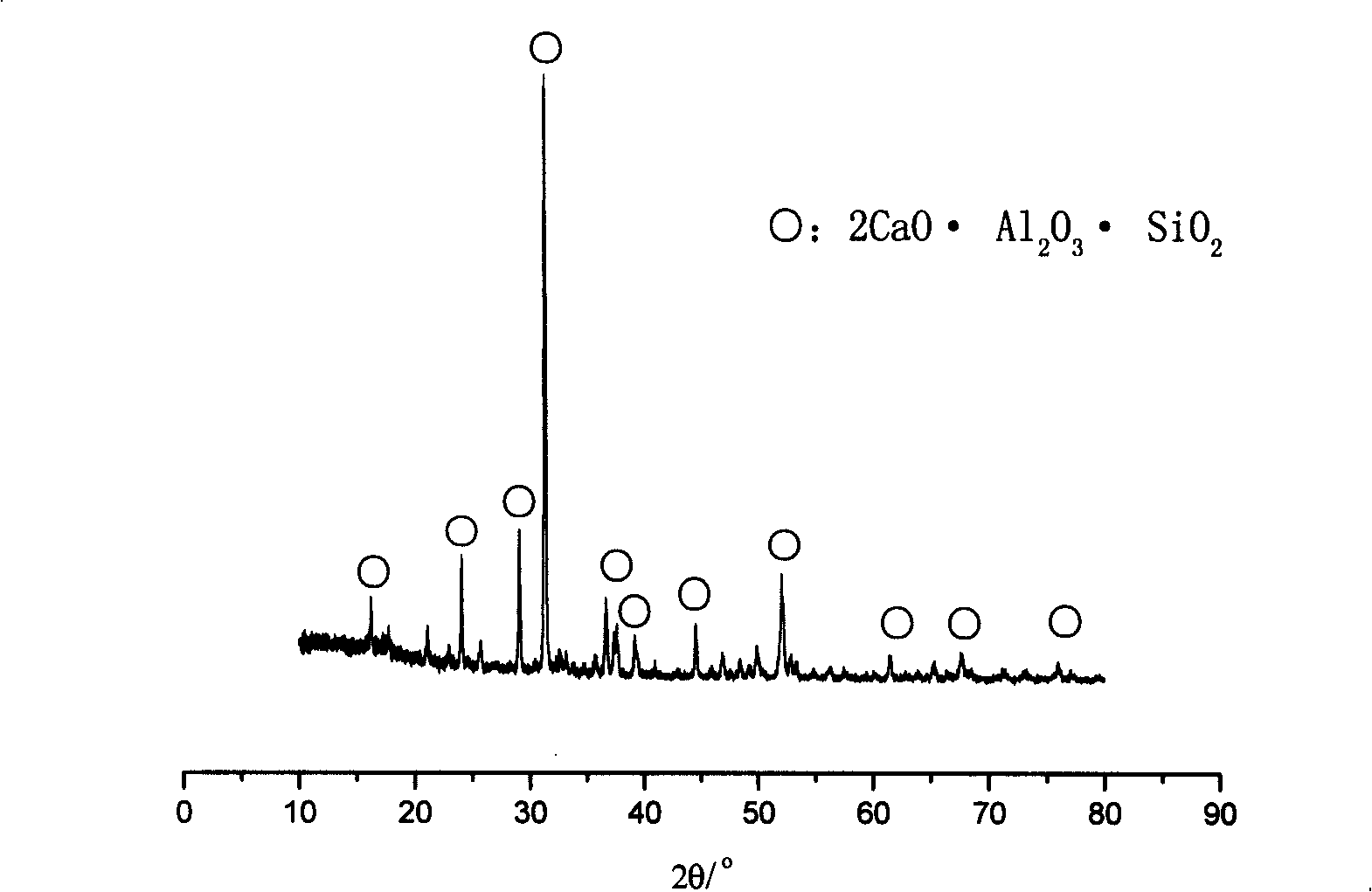

[0021] (4) Crystallize at 850°C for 2 hours, sinter at 1170°C for 1 hour, and the heating rate is 5°C / min. After polishing, the slag glass-ceramic is obtained, and the main crystal phase is calcium yellow feldspar (2CaO·Al 2 o 3 ·SiO2 2 ). The density of the prepared glass-ceramic is 2.67g / cm 3 , Vickers hardness is 4.65GPa, water absorption rate is 0.11%....

Embodiment 2

[0024] The raw material composition of glass-ceramic is 95wt% slag, 5wt% feldspar. The pre-process conditions are as in Example 1, the ratio of material, balls and water is 1.5:2:1.5 when the ball mill is mixed to prepare the slurry, and the slurry is dried at 80°C until the water content is ≤4%, and then 3% by weight of water is added to granulate , Tablet crystallization and sintering parameters are compression molding at 30MPa, crystallization at 950°C for 1 hour, sintering at 1150°C for 2 hours, and a heating rate of 2°C / min. After polishing, the slag glass-ceramic with calcium feldspar as the main crystal phase is obtained. The density of glass-ceramic is 2.75g / cm 3 , Vickers hardness is 5.15GPa, water absorption rate is 0.20%.

Embodiment 3

[0026] The raw material composition of glass-ceramic is 92wt% slag, 3wt% zircon and 5wt% feldspar. The pre-process conditions are as in Example 1, the ratio of material, balls, and water is 2:1:1 when the ball mill is mixed to prepare the slurry, and the slurry is dried at 90°C until the moisture content is ≤3%, and then water with a weight ratio of 5% is added to granulate , Tablet crystallization and sintering parameters are compression molding at 40MPa, crystallization at 900°C for 1 hour, sintering at 1200°C for 1.5 hours, and a heating rate of 10°C / min. After polishing, the slag glass-ceramic with calcium feldspar as the main crystal phase is obtained. The density of glass-ceramic is 2.78g / cm 3 , the Vickers hardness is 5.20GPa, and the water absorption rate is 0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com