Liver-protecting and alcoholism-relieving product using Saccharomyces cerevisiae as main material

A technology of Saccharomyces cerevisiae, the main raw material, applied in the field of liver protection and hangover products, which can solve the problems of poor uniformity of effective content, failure to achieve liver protection and hangover effects, and low content of B vitamins and glutathione

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

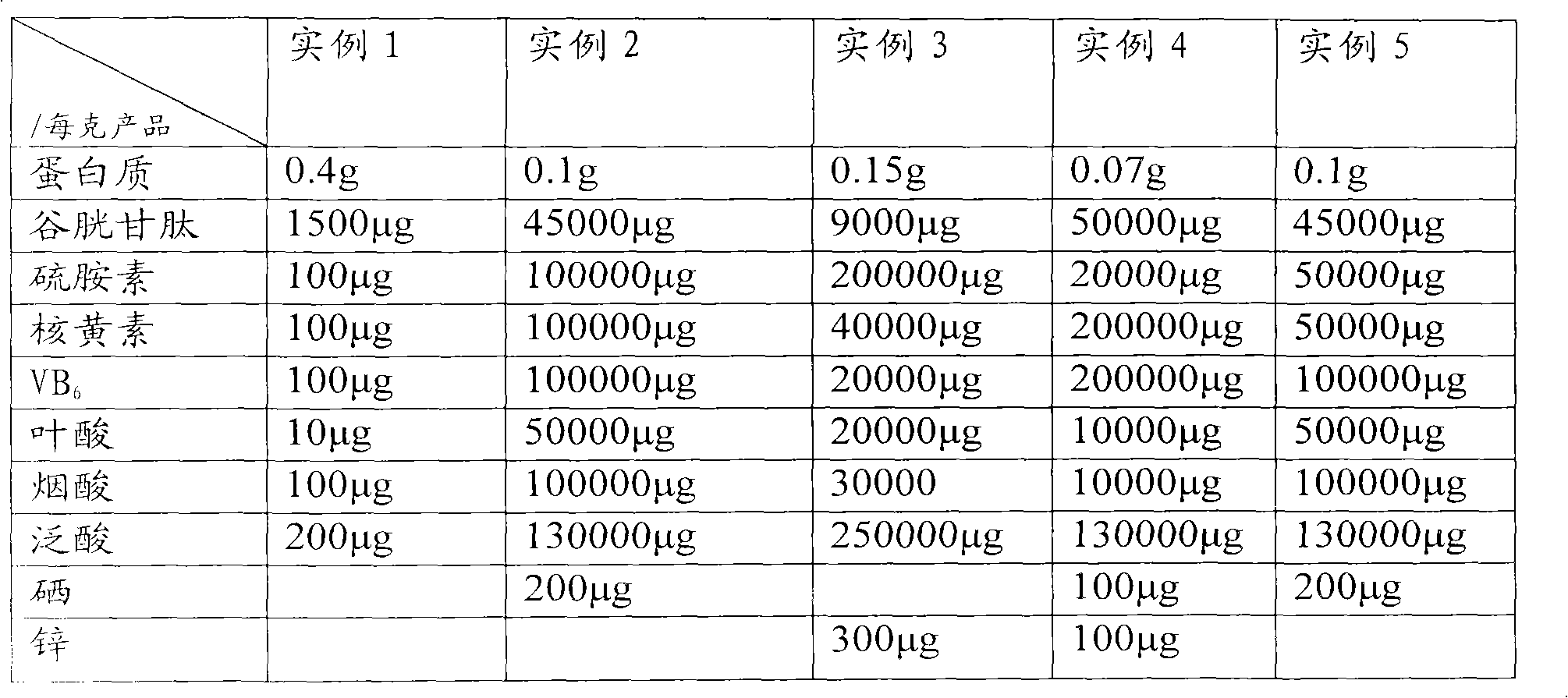

example 1

[0019] Materials used: baker's yeast (belonging to the genus Saccharomyces cerevisiae), starch

[0020] Preparation process: Mix the screened baker's yeast and starch according to the mass ratio of 80:20, and prepare an emulsion containing 20% dry matter with water; fully stir to obtain a uniform emulsion; the steam pressure in the heating drum is Under the pressure of 0.5-0.65MPa, the emulsion is dried into a snowflake-like substance or pulverized into a powder in a drum; the obtained snowflake-like or powdery substance is divided into polyethylene bottles.

[0021] All the above steps are carried out in the 300,000-level GMP (drug manufacturing quality standard) workshop to ensure the hygiene and safety of the product.

example 2

[0023] Materials used: 20% baker's yeast, 5% glutathione, 10% thiamine, 10% riboflavin, 10% VB 6 , 10% nicotinamide, 15% calcium pantothenate, 5% folic acid, 10% selenium-enriched yeast (2000ppm selenium) and 5% starch, and the above percentages are all percentages by mass.

[0024] making process:

[0025] 1) Pulverization: pulverize the material of the above formula with a pulverizer, and then pass the obtained powder through an 80-mesh sieve;

[0026] 2) Mixing: fully mix the obtained powder evenly;

[0027] 3) Filling and packaging: Fill the mixed powder into capsules, 0.1-0.5g per capsule;

[0028] Each step is carried out in a 300,000-level GMP workshop to ensure product hygiene and safety.

example 3

[0030] Materials used: 30% brewer's yeast (belonging to Saccharomyces cerevisiae), 1% glutathione, 20% thiamine, 4% riboflavin, 2% VB 6 , 3% nicotinamide, 28% calcium pantothenate, 2% folic acid and 10% zinc-rich yeast (3000ppm zinc), the above percentages are mass percentages.

[0031] making process:

[0032] 1) Mix the various materials evenly according to the above-mentioned formula quantity, and pass through a 100-mesh sieve after pulverizing with a pulverizer;

[0033] 2) Dosing: use water as a solvent to make a suspension solution from the obtained powder;

[0034] 3) filling the obtained solution in a glass bottle container, and autoclaving at 121°C;

[0035] Each step is carried out in a 300,000-level GMP workshop to ensure product hygiene and safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com