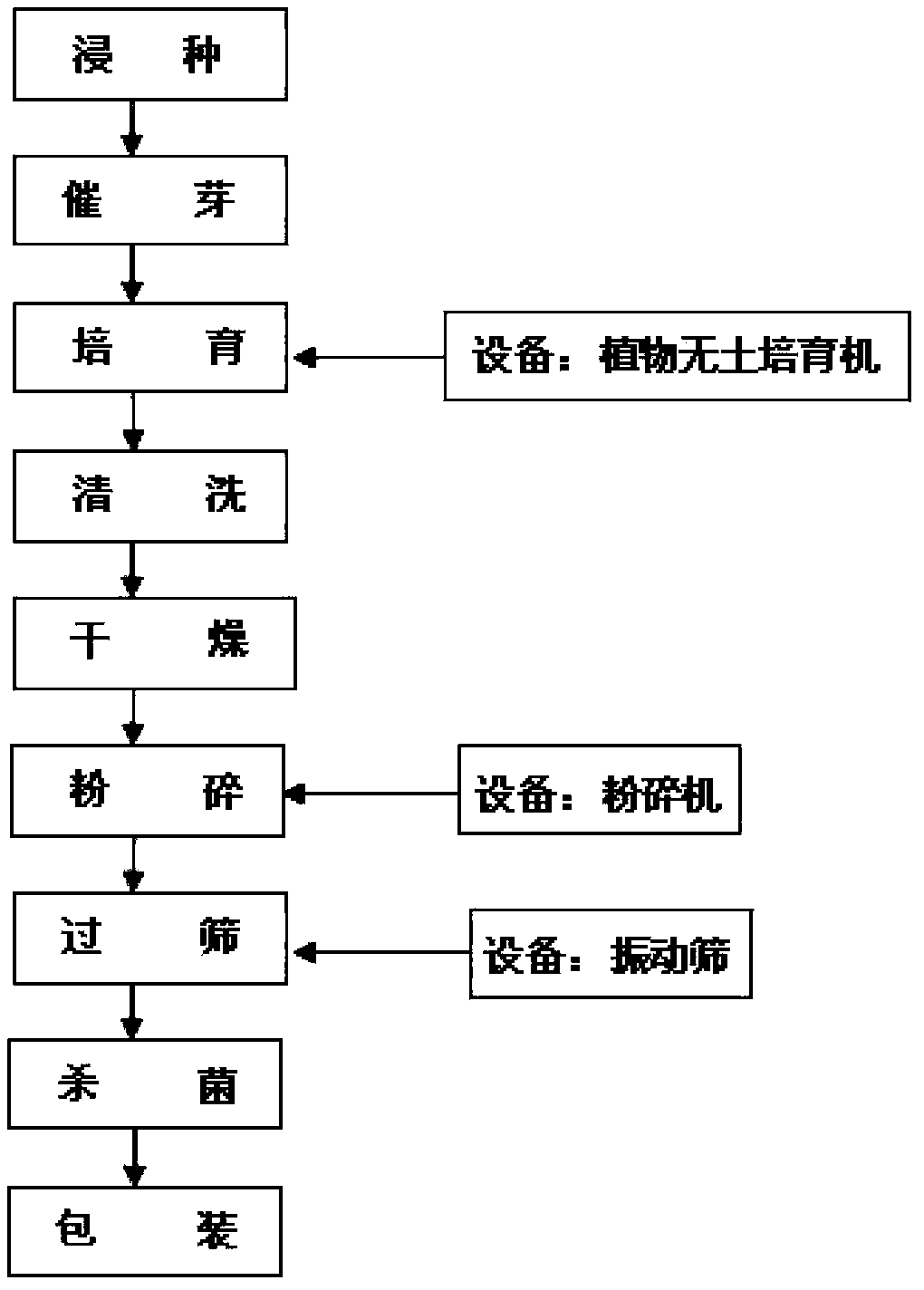

Processing technology of selenium enriched malt powder and soilless cultivation machine for plant

The technology of selenium-enriched malt powder and processing technology is applied in the field of machinery and equipment, and can solve the problems of low selenium content in selenium-enriched malt, failing to meet the demand of selenium element, affecting plant productivity and the like, and achieving the effect of increasing selenium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] (1) Seed soaking: put 500 kg of wheat into the pool and wash it twice, soak it in potassium permanganate water prepared with a weight ratio of 1:1000 between potassium permanganate and water for 10 minutes, and then soak it in nutrient solution. The composition of the liquid is: 100000 parts of tap water, the parts by weight of various raw materials are: 0.01 part of zinc sulfate, 0.2 part of gibberellin, 10 parts of magnesium sulfate, 50 parts of calcium sulfate, 0.01 part of ferrous sulfate, potassium dihydrogen sulfate 10 parts, 0.1 part of sodium selenite, the water temperature is 15°C, the pH is 5, the time is 15 hours, and the room temperature is 18°C.

[0030] (2) Germination: take out the wheat from the soaking tank and place it on a plate for germination at a temperature of 15 degrees for 0.5 days.

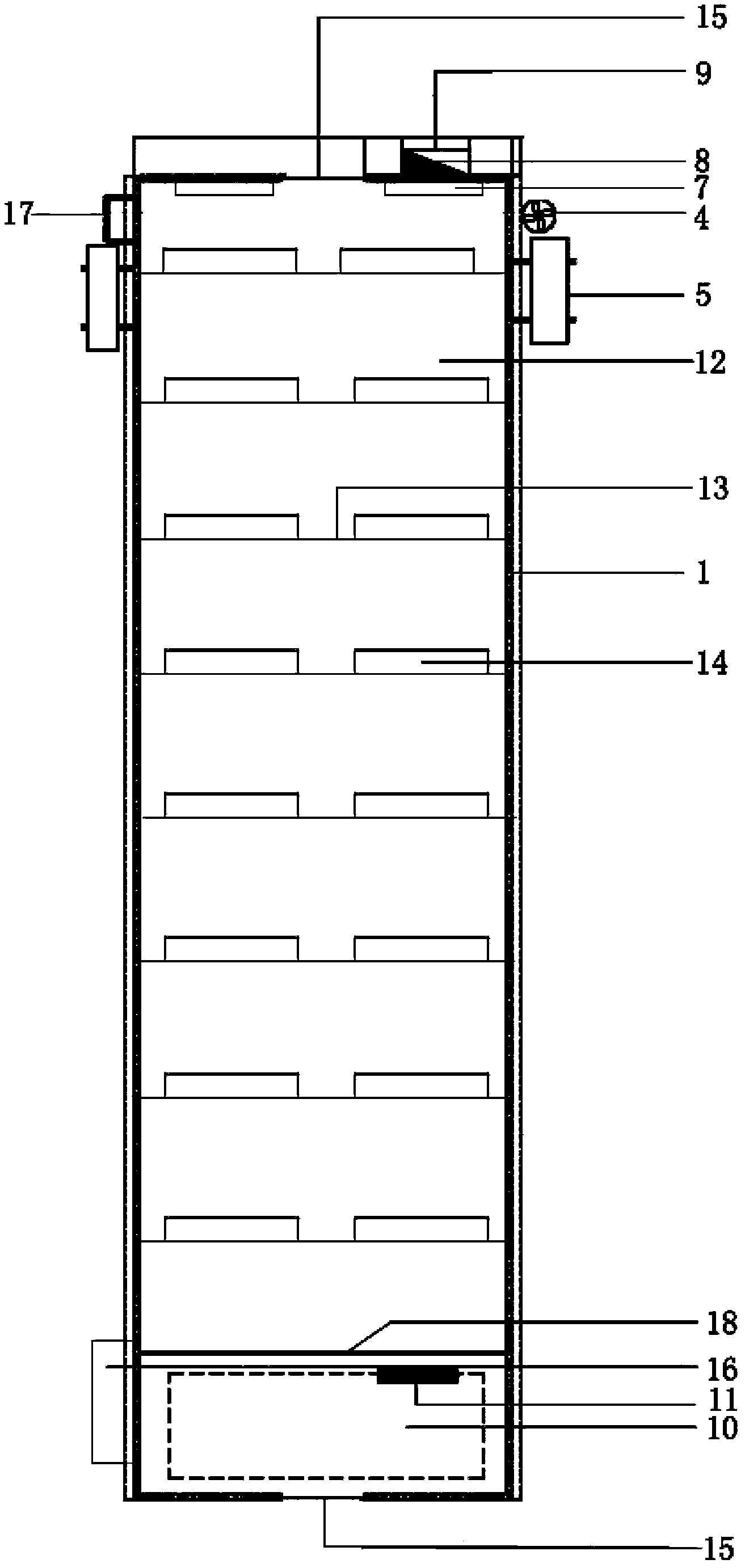

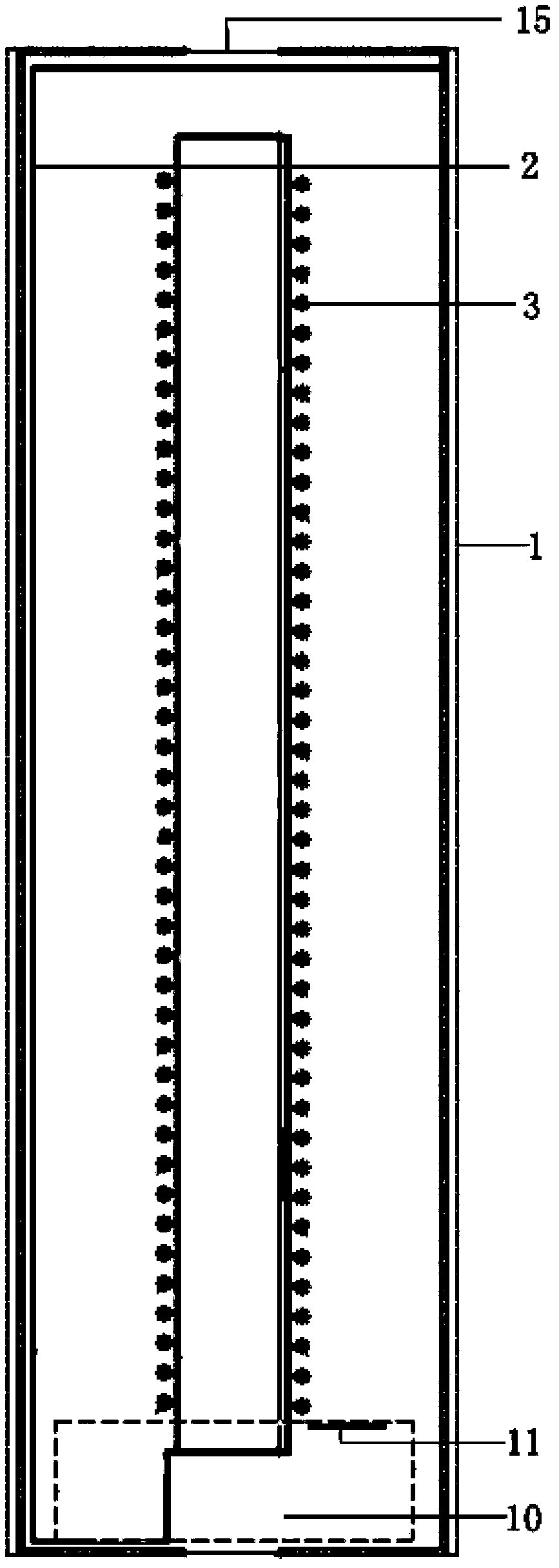

[0031] (3) Cultivation: After the germination is completed, the wheat is placed in a cultivation tray and placed in a plant soilless cultivation machine for cultiv...

example 2

[0040] (1) Seed soaking: Soak in potassium permanganate water prepared with a weight ratio of potassium permanganate and water at a ratio of 1:1000 for 10 minutes, and then soak in nutrient solution. The composition of nutrient solution is: 100,000 parts of tap water, various The parts by weight of raw materials are: 2 parts of zinc sulfate, 4 parts of gibberellin, 20 parts of magnesium sulfate, 60 parts of calcium sulfate, 4 parts of ferrous sulfate, 15 parts of potassium dihydrogen sulfate, 0.8 parts of sodium selenite, and the water temperature is 23°C , the pH is 6, the time is 19 hours, and the room temperature is 24°C.

[0041] (2) Germination: Take the wheat out of the soaking tank and place it on a plate for germination at 23°C for 1.5 days.

[0042] (3) Cultivation: After the germination is completed, the wheat is placed in a cultivation tray and placed in a plant soilless cultivation machine for cultivation at a temperature of 24°C and a humidity of 70% for 10 days. ...

example 3

[0051] (1) Seed soaking. Clean the pool and add clean water, put the wheat in the pool and wash it twice, soak it in potassium permanganate water prepared in the ratio of potassium permanganate and water according to the weight ratio of 1:1000 for 10 minutes, and then soak it in nutrient solution. The composition of the liquid is: 100000 parts of tap water, the parts by weight of various raw materials are: 5 parts of zinc sulfate, 10 parts of gibberellin, 30 parts of magnesium sulfate, 70 parts of calcium sulfate, 10 parts of ferrous sulfate, 20 parts of potassium dihydrogen sulfate 2 parts, 2 parts of sodium selenite, the water temperature is 30°C, the pH is 7, the time is 24 hours, and the room temperature is 30°C.

[0052](2) Germination: Take the wheat out of the soaking tank and place it on a plate for germination at 30°C for 3 days.

[0053] (3) Cultivation: After the germination is completed, the wheat is placed in a cultivation tray and placed in a plant soilless cult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com