Sludge treatment method and application thereof

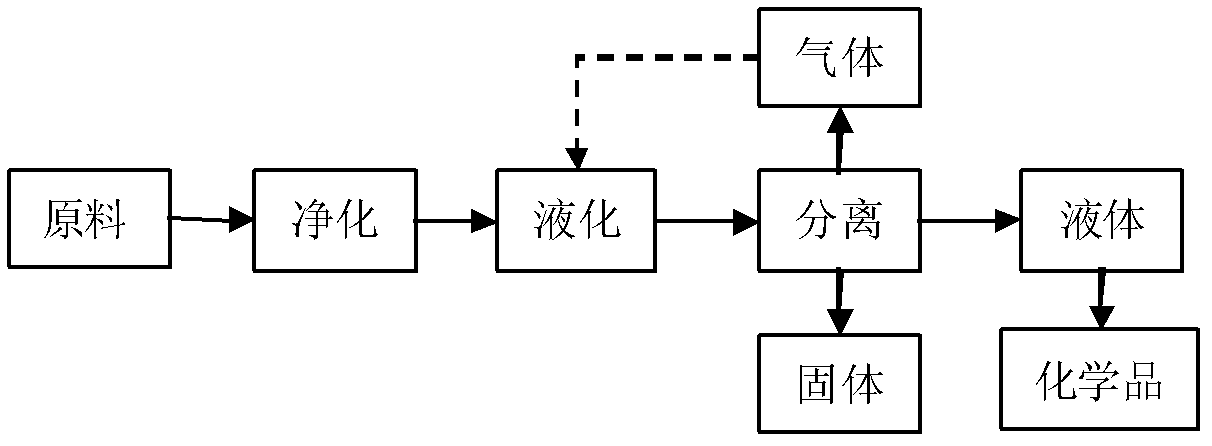

A sludge treatment and sludge technology, applied in the application field of sludge treatment, can solve the problems of low treatment capacity per unit time, long residence time, low utilization rate of organic matter, etc., to achieve resource utilization, improve mass transfer and The effect of heat transfer rate, reaction rate acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

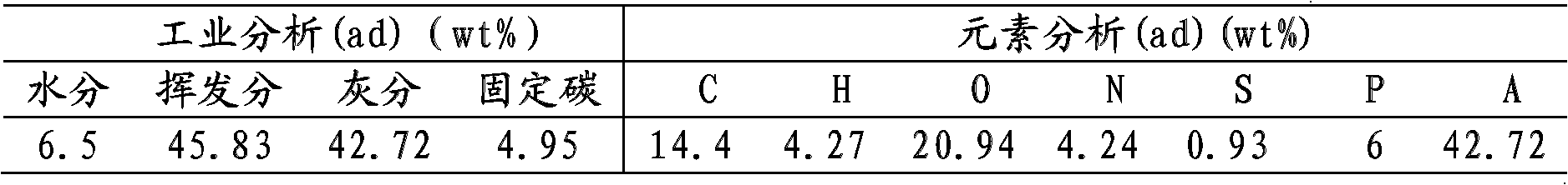

[0031] Sand was removed by gravity sedimentation, and the raw sludge from municipal sludge was purified to form a slurry with a sludge concentration of 15 wt%. Then the slurry was put into a reactor, and the reactor was controlled at a temperature of 350° C. and a reaction pressure of 17.0 MPa, and the sludge was reacted for 10 minutes under these conditions.

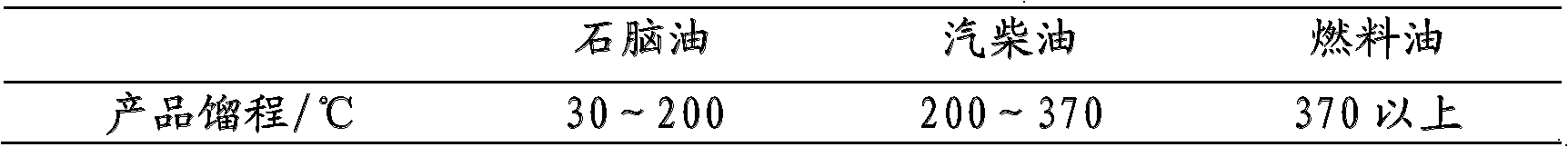

[0032] After the above reaction is finished, the reactant is taken out from the reactor, cooled, and then distilled to obtain a liquid product, which is an oil product. The liquid product is measured by an Agilent gas chromatography mass spectrometer. As a result, it is known that in this product, naphtha The content of gasoline and diesel oil is 52wt%, the content of gasoline and diesel oil is 28wt%, and the content of fuel oil is 20wt%, and the rest are various impurities. Table 3 shows the reaction conditions of this example together with the results obtained by the above measurements.

[0033] The distillation rang...

Embodiment 2~16

[0037] Examples 2-16 were carried out with the operation similar to that of Example 1, except that the reaction conditions were different. The specific reaction conditions and reaction results are shown in Table 3.1-3.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com