Macropore high-capacity agarose gel media preparing method

An agarose gel, high-capacity technology, used in chemical instruments and methods, measuring devices, material separation, etc., can solve the problems of difficult pore size control, medium performance and use effects, and complex preparation processes, achieving simple equipment and raw materials. Inexpensive, biocompatible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

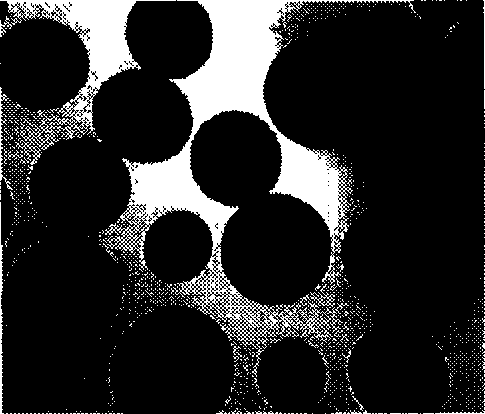

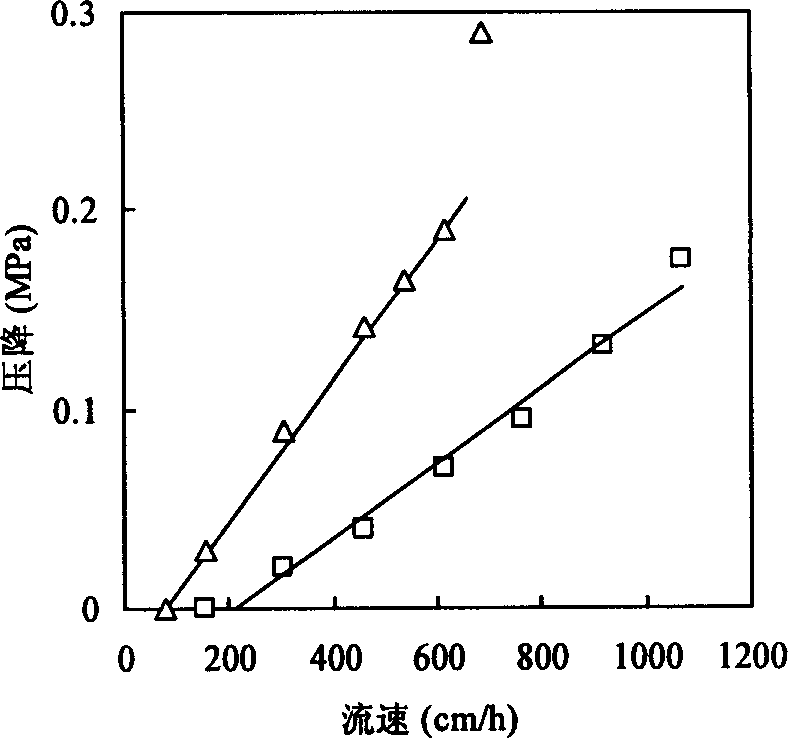

[0020]At 90°C, 4.5 g of the processed calcium carbonate particles with a particle size of 2.67 μm and a distribution of 0.86 to 4.58 m were uniformly dispersed in 50 mL of 60 g / L agarose solution by rapid stirring. Then quickly pour the suspension into 300mL organic phase containing 30g / L Span80, and control the stirring speed at 1200rpm at 90°C; after reacting for 30min, quickly cool down to 20°C, and continue to The solidification reaction was carried out for 40 minutes; water twice its volume was added to the above reaction system, and an agarose gel medium wrapped with calcium carbonate particles was obtained by natural sedimentation. The collected microspheres were washed repeatedly with acetone and distilled water successively to remove the residual organic phase. Take 50mL of washed microspheres and mix them with an equal volume of 1mol / L sodium hydroxide solution, then add 500mg of sodium borohydride to make the concentration of sodium borohydride in the suspension 5g / ...

Embodiment 2

[0022] At 85° C., 6 g of processed calcium carbonate particles with a particle size of 2.67 μm and a distribution of 0.86 to 4.58 μm were uniformly dispersed in 50 mL of 60 g / L agarose solution by rapid stirring. Then quickly pour the suspension into 300mL organic phase containing 30g / L Span80, and react for 15min at a wrapping temperature of 85°C and a stirring speed of 1300rpm; rapidly cool down to 15°C, and solidify while maintaining a constant stirring speed React for 30 minutes; add twice the volume of water to the above system, and obtain an agarose gel medium wrapped with calcium carbonate particles through natural sedimentation. The collected microspheres were washed repeatedly with acetone and distilled water until the organic phase was completely removed. Take 50mL of washed microspheres and mix them with an equal volume of 1mol / L sodium hydroxide solution, then add 400mg of sodium borohydride to make the concentration of sodium borohydride in the suspension 4g / L. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com