High-selectivity decarbonization absorbent adopting physical method

A high-selectivity, absorbent technology, used in chemical gas separation and purification, coal combustion, and petroleum fields, can solve problems such as unreported, lower combustion calorific value, slow combustion speed, etc., to achieve good separation effect and improve selectivity. , the effect of improving the absorption and mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

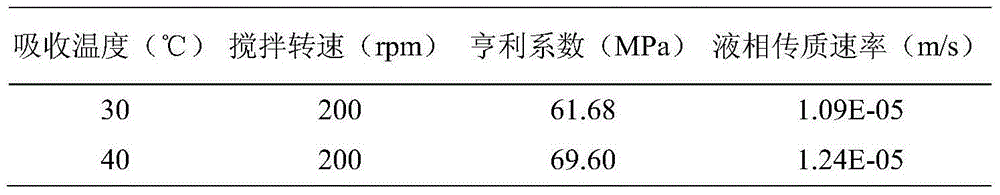

Embodiment 1

[0017] a) add 20g containing 75wt% [bmim] [BF 4 ], vacuumize both the gas buffer tank and the absorption tank, control the temperature of the water bath to 30°C and 40°C respectively, control the stirring rate to 200rpm, close the valve between the absorption tank and the gas buffer tank, and keep the absorption tank in vacuum. Pour a certain amount of methane gas into the gas buffer tank to make the pressure reach 1MPa, and preheat for 1 hour. After the preheating is over, open the valve between the absorber and the gas buffer tank and then close it quickly. After closing the valve, record the pressure drop change of the absorber continuously for 10 minutes, and record the final pressure after the pressure in the absorber is balanced.

[0018] b) The Henry coefficient of methane gas in the absorbent is calculated according to the thermodynamic model, and the liquid phase mass transfer coefficient of methane gas in the absorbent is calculated according to the kinetic model. T...

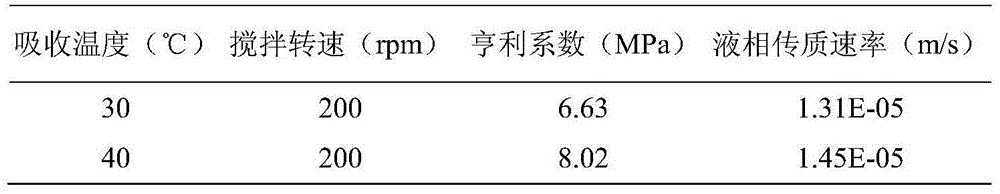

Embodiment 2

[0022] a) Add 20g of absorbent containing 75wt% [bmim][DCA] to the absorption kettle, vacuum the gas buffer tank and the absorption kettle, control the temperature of the water bath at 30°C, 40°C, control the stirring rate at 200rpm, close the absorption kettle and the gas The valve between the buffer tanks keeps the absorber in vacuum, injects a certain amount of carbon dioxide gas into the gas buffer tank to make the pressure reach 1MPa, and preheats for 1 hour. After the preheating is over, open the valve between the absorber and the gas buffer tank and then close it quickly. After closing the valve, record the pressure drop change of the absorber continuously for 10 minutes, and record the final pressure after the pressure in the absorber is balanced.

[0023] b) The Henry coefficient of carbon dioxide gas in the absorbent is calculated according to the thermodynamic model, and the liquid-phase mass transfer coefficient of carbon dioxide gas in the absorbent is calculated a...

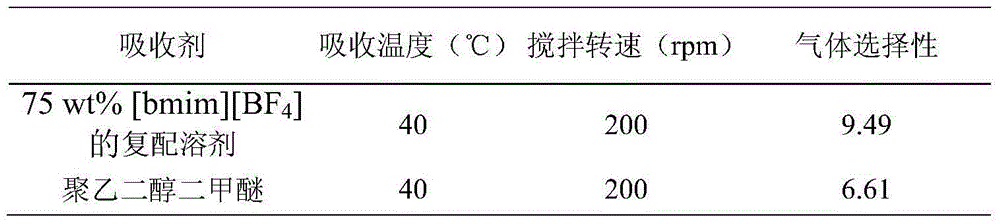

Embodiment 3

[0027] a) At a temperature of 40°C and a rotational speed of 200rpm, add 20g of 75wt% [bmim][BF 4 ] of the absorbent, and measure the gas selectivity of the absorbent to separate methane and carbon dioxide under the proportioning.

[0028] b) Adding 20 g of polyethylene glycol dimethyl ether into the absorption tank respectively as a blank experiment to measure the gas selectivity of the polyethylene glycol dimethyl ether for separating methane and carbon dioxide. The comparative test results are shown in the following table (Table 3):

[0029] Table 3 The comparison of compound solvent and polyethylene glycol dimethyl ether gas selectivity

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com