Combined process for preparing power generation co-production synthesis ammonia feed gas by using crude gas containing CH4

A combined process and ammonia synthesis technology, which is applied in the direction of catalytic treatment of combustible gas, solid contact hydrogen separation, chemical recovery, etc., can solve the problems of high consumption of raw material gas for ammonia synthesis and low conversion rate of methanol, etc., and achieve obvious environmental protection effect and smooth operation The effect of low cost and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

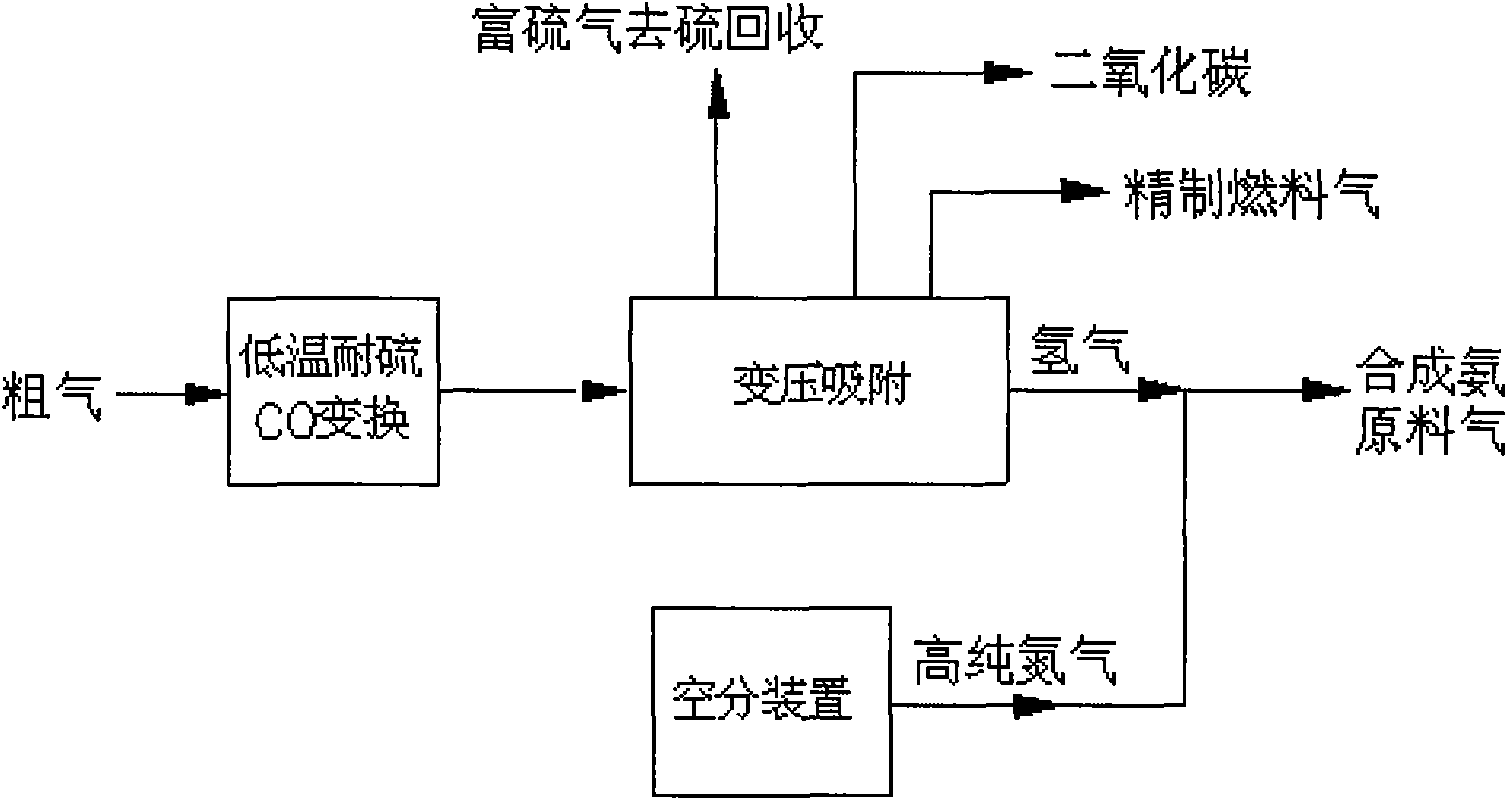

[0020] A combined process for producing raw material gas for power generation and co-production ammonia synthesis with methane-containing crude gas, the process flow is as follows figure 2 As shown, the process includes the following steps:

[0021] Contains CH 4 The crude gas composition is as follows: CO 2 : 20.5%, CO: 40%, H 2 : 25.3%, CH 4 : 7.5%, C n h m : 0.5%, H 2 S+COS: 1.3%, N 2 +Ar: 4.9%, control temperature 30℃, feed gas 75000Nm pressure 2.1Mpag 3 / h enters the low-temperature sulfur-resistant CO shift reaction to transform CO into hydrogen. The low-temperature sulfur-tolerant transformation process uses a sulfur-tolerant cobalt-molybdenum catalyst supported by regenerated spinel for transformation, and an organic sulfur conversion device is installed in the transformation section. The low-temperature sulfur-tolerant conversion is used to adjust the conversion rate of CO, and finally adjust the ratio of the gas volume of ammonia synthesis feed gas to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com