Desulfurization and decarburization integrated absorption process for polyglycol dimethyl ether

A technology of polyethylene glycol dimethyl ether and glycol dimethyl ether, which is applied in the field of polyethylene glycol dimethyl ether desulfurization and decarbonization integrated absorption process, can solve the problems of large investment and many operating equipment, and achieves low investment. , less operating equipment, the effect of improving the regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

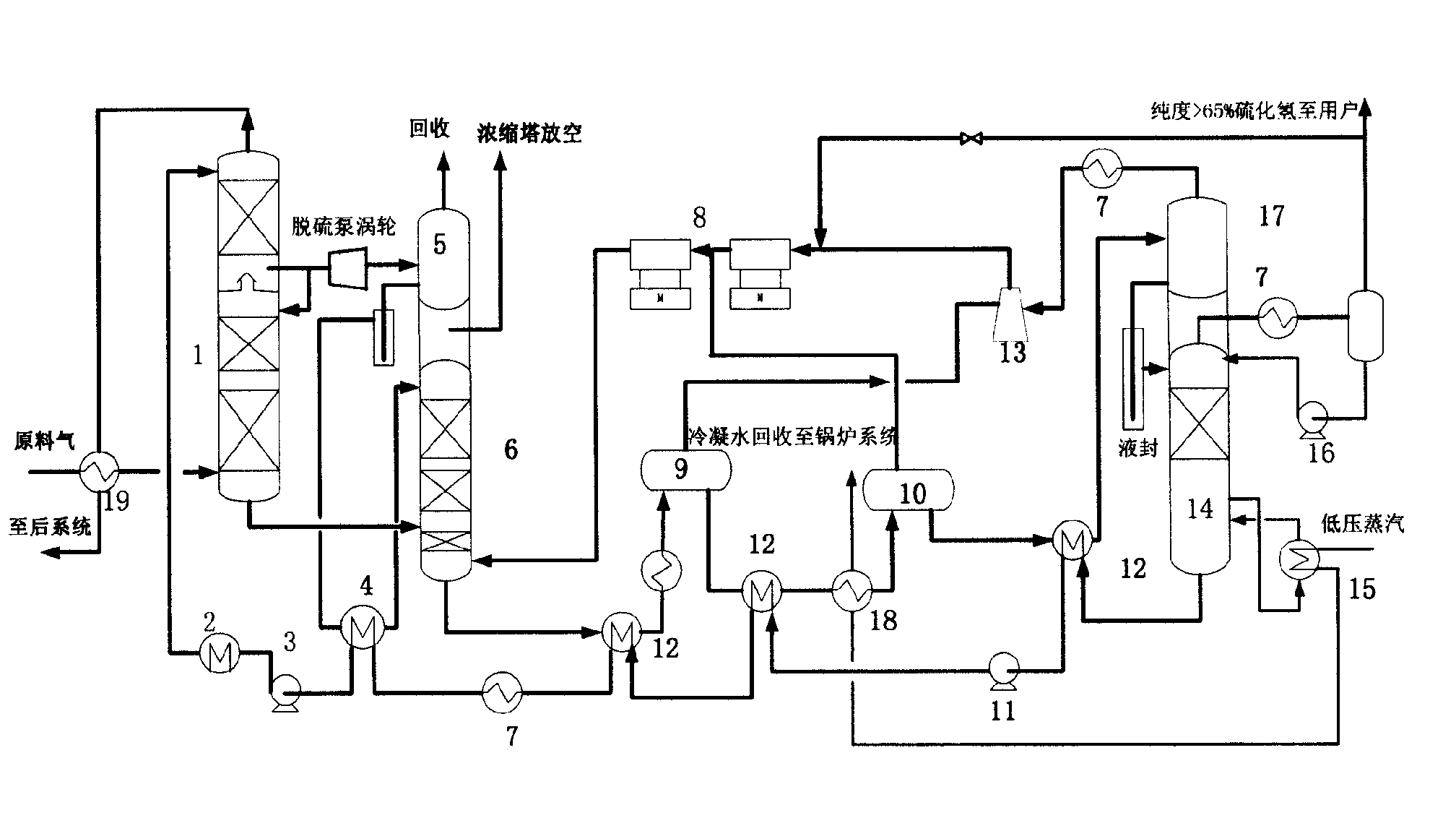

[0026] figure 1 The technical process of the present invention is specifically described as follows:

[0027] 1. The raw material gas with a pressure of 2.0-6.5Mpa and a temperature of 20-25°C passes through the gas heat exchanger 19 to exchange heat with the purified gas after absorption, and the temperature is 5-20°C, and is sent to the absorption tower 1 after separation. The absorption tower 1 is in countercurrent contact with the NHD solution for full absorption. The lower section of absorption tower 1 is mainly the desulfurization section. The desulfurized gas enters the decarburization section through the gas lift cap, and the purified gas after decarburization (hydrogen sulfide≤2ppm, CO 2 ≤5%) at a temperature of about -10 to 15°C. After separation, the raw material gas is cooled by the ammonia cooler 2 to recover the cooling capacity, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com