Method for measuring content of acid gas in polyethylene glycol dimethyl ether absorption solution

A polyethylene glycol dimethyl ether, acid gas technology, applied in chemical method analysis, measurement device, preparation of test samples, etc., to achieve the effect of optimizing system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

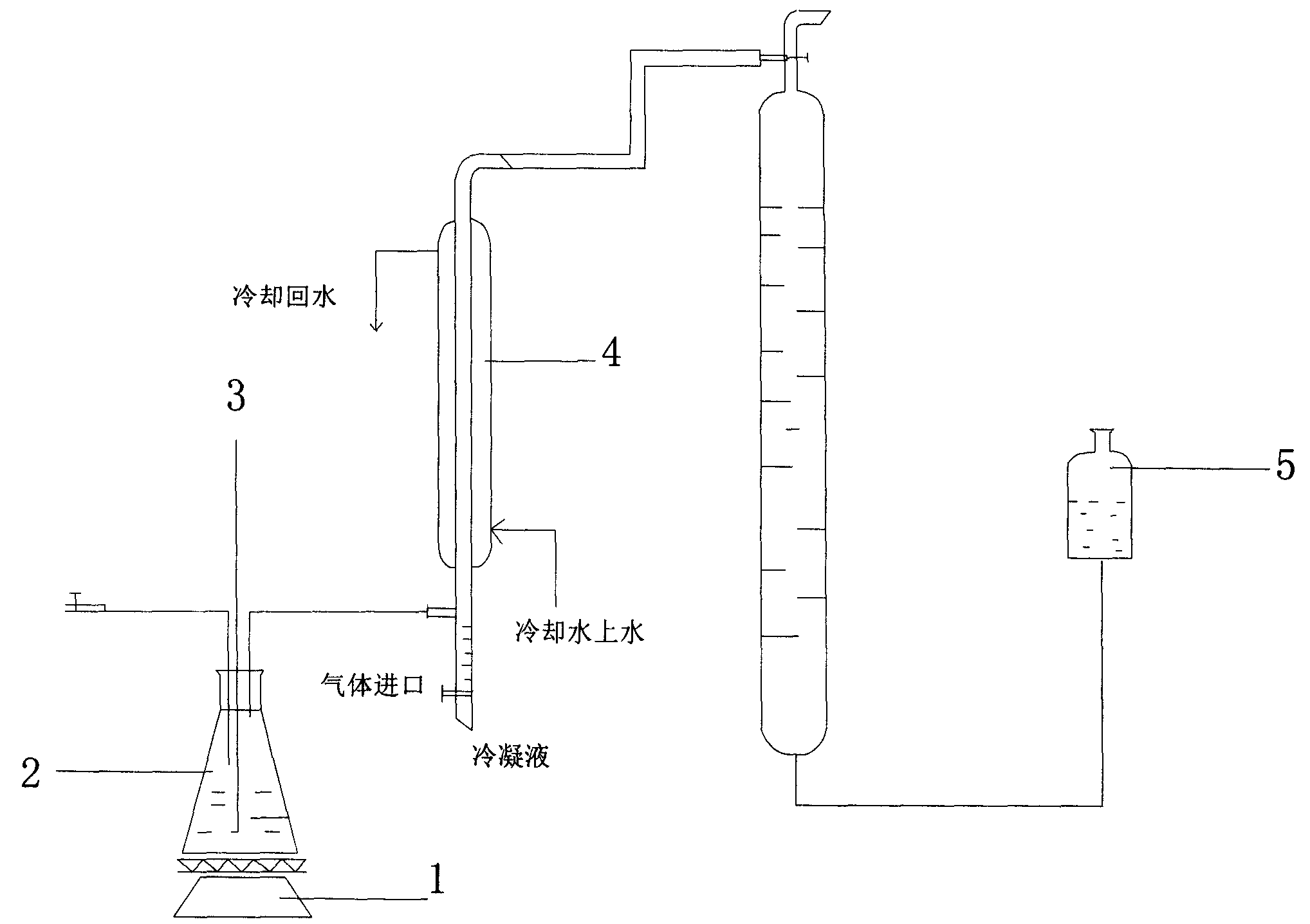

[0043] Embodiment Qualitative and quantitative analysis of rich liquid rich in hydrogen sulfide

[0044] (1) measuring the total volume of the Erlenmeyer flask 2 is 430ml, measuring the total gas volume 40ml in the condenser tube 4, and measuring the total volume of the joint rubber tube 10ml;

[0045] (2) Connect nitrogen gas from the gas inlet for replacement, and then seal the gas collecting bottle 5 to the zero mark with sealing liquid.

[0046] (3) Close the cock at the bottom of the condensation pipe 4, and feed cooling water.

[0047] (4) Introduce 250ml of absorption liquid into the production device. (here the solution is a rich solution)

[0048] (5) Heating by the water bath heating device 1, opening the three-way connection of the gas collecting bottle 5 to collect the gas. The heating temperature is controlled slightly lower than the boiling point temperature of the solution by a thermometer 3.

[0049] (6) When the heating temperature reaches about the boilin...

Embodiment 2

[0059] Example 2 Qualitative and quantitative analysis of lean liquid containing less hydrogen sulfide

[0060] (1) measuring the total volume of the Erlenmeyer flask 2 is 430ml, measuring the total gas volume 40ml in the condenser tube 4, and measuring the total volume of the joint rubber tube 10ml;

[0061] (2) Connect nitrogen gas from the gas inlet for replacement, and then seal the gas collecting bottle 5 to the zero mark with sealing liquid.

[0062] (3) Close the cock at the bottom of the condensation pipe 4, and feed cooling water.

[0063] (4) Introduce 250ml of absorption liquid into the production device. (The solution here is a poor solution)

[0064] (5) Heating by the water bath heating device 1, opening the three-way connection of the gas collecting bottle 5 to collect the gas. The heating temperature is controlled slightly lower than the boiling point temperature of the solution by a thermometer 3.

[0065] (6) When the heating temperature reaches about the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com