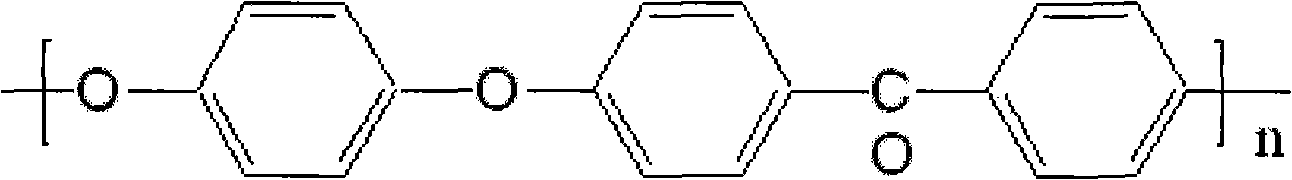

Manufacturing method of polyether-ether-ketone thin film

A technology of polyether ether ketone film and manufacturing method, which is applied in the field of polymer material resin, and can solve the problems of unsatisfactory film crystallization performance results and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

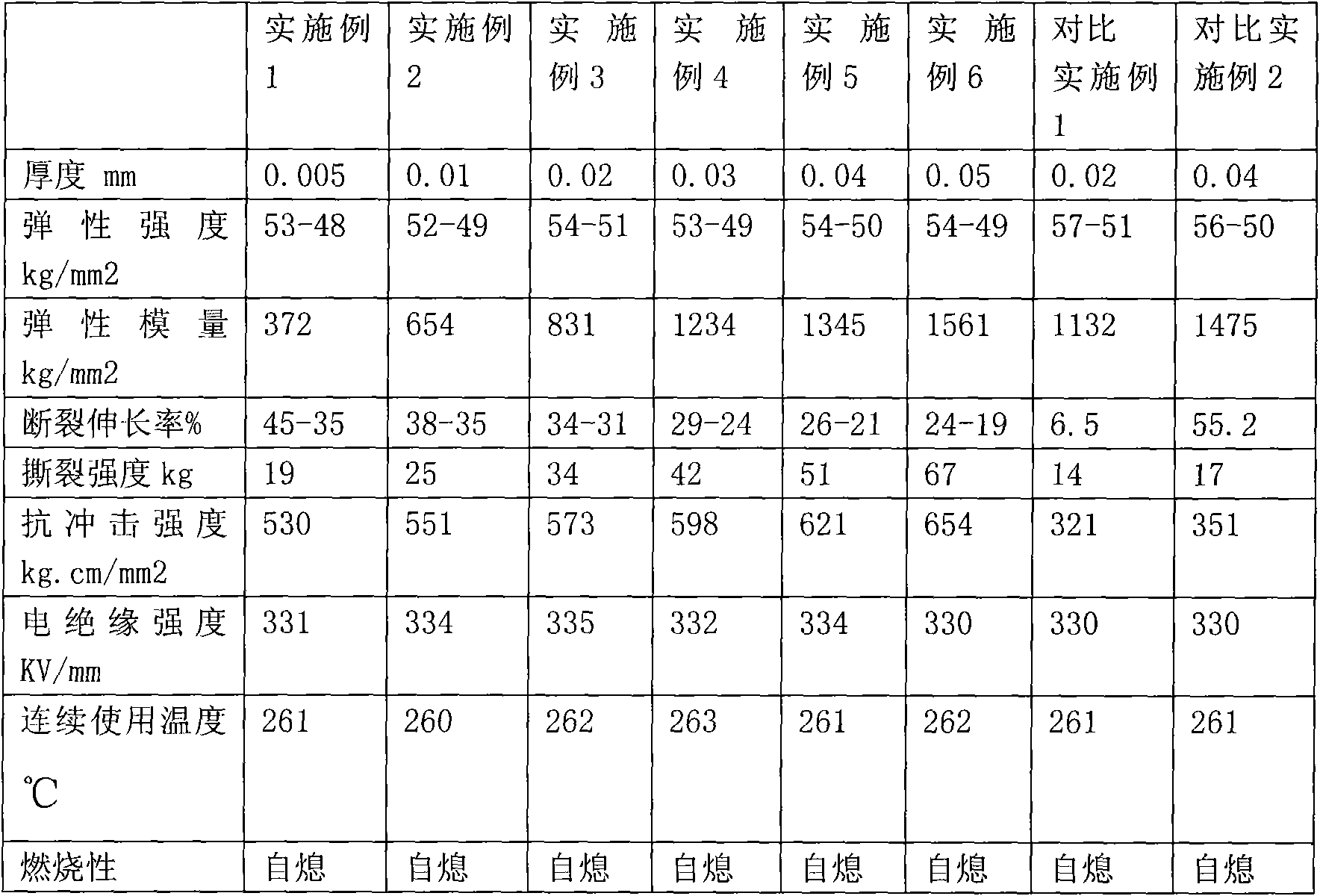

Examples

Embodiment 1

[0039] Add 218.2kg of 4,4'-difluorobenzophenone into a reaction polymerization kettle with 1842kg of sulfolane as a solvent, heat it with an electric heater, feed in nitrogen and keep stirring, when the temperature rises to 150-160°C, Add 106kg anhydrous alkali metal carbonate, 228.29kg bisphenol A respectively again successively; The mol ratio of 4,4'-difluorobenzophenone and bisphenol A and alkali metal carbonate is 1: 1: 1, So that the solid-liquid ratio is 0.25-0.3: 1; then continue to heat up, when the temperature rises to 250 ° C, after 3 hours of heat preservation, the temperature is then raised to 290 ° C for 6 hours of heat preservation. Then the mixture was poured into ice water at -5°C, rapidly cooled to normal temperature, and filtered, then the sulfolane solvent in the mixture was washed out with 30% chloroform-containing absolute ethanol, and finally the mixture was repeatedly washed with deionized water to obtain High polyether ether ketone resin.

[0040] The ...

Embodiment 2

[0048] The polyetheretherketone resin was synthesized using the process conditions and data in Example 1, thereby obtaining a polyetheretherketone resin with low purity.

[0049] The polyether ether ketone resin obtained above was re-added into the washing tank filled with sulfolane solvent containing 30% deionized water, and heated to 220° C. for 1 hour. Filtrate while it is hot, then pour the mixture into ice water at -5°C, rapidly cool to room temperature, and filter, then wash out the sulfolane solvent in the mixture with acetone, and finally wash the mixture repeatedly with deionized water, and dry to obtain the melt flow index It is 10.3g / 10min polyetheretherketone resin.

[0050] Utilize the above process to obtain the polyether ether ketone resin with the addition of inorganic fillers and organic compounds: 91.6% polyether ether ketone, 0.3% inorganic filler nano-scale silica, 8.1% organic filler polyester resin, and mix these materials into Film premix, the film prem...

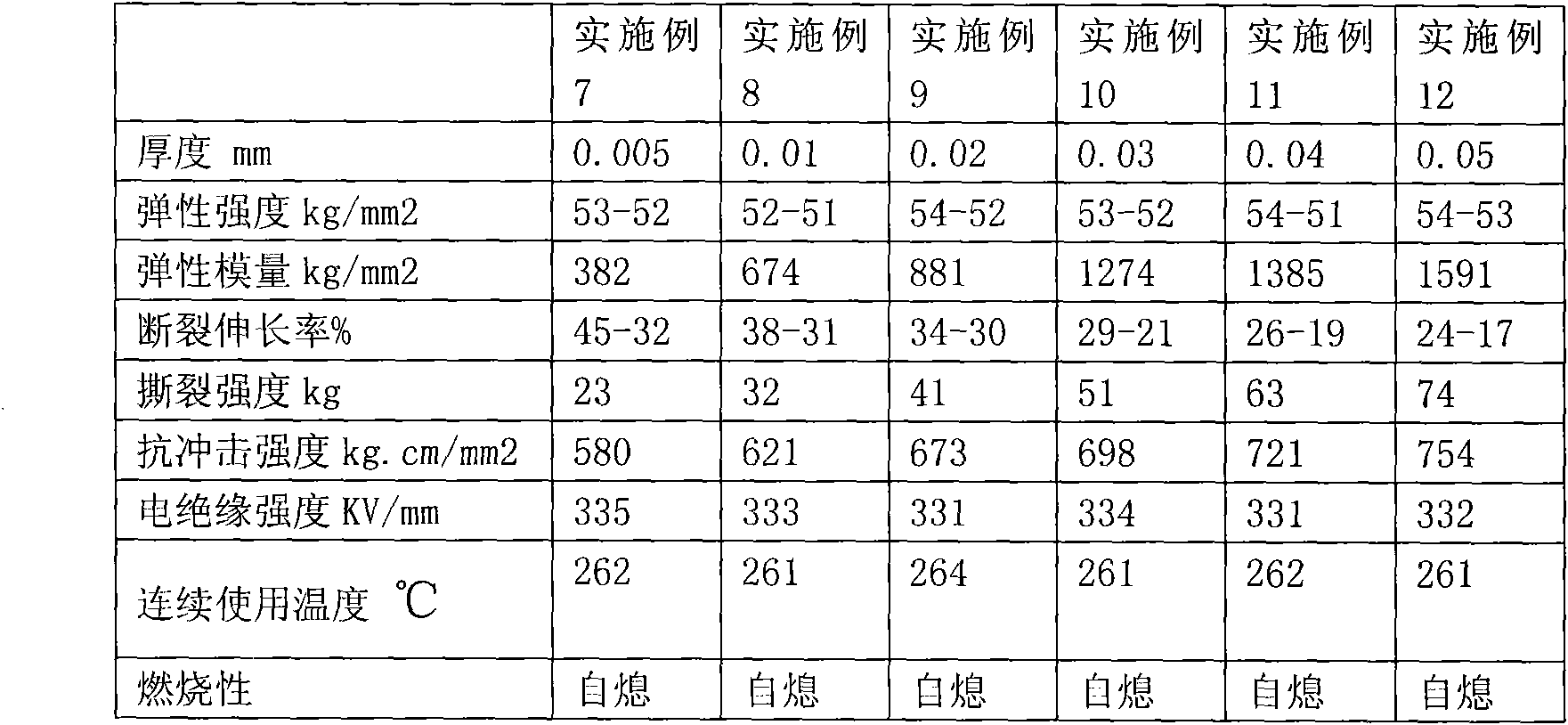

Embodiment 3

[0057] The polyetheretherketone resin was synthesized using the process conditions and data in Example 1, thereby obtaining a polyetheretherketone resin with low purity.

[0058] The polyether ether ketone resin obtained above was added again into the washing kettle containing sulfolane solvent containing 30% deionized water, and heated to 214° C. for 1.3 hours. Filtrate while it is hot, then pour the mixture into ice water at -1°C, rapidly cool to room temperature, and filter, then wash out the sulfolane solvent in the mixture with absolute ethanol, and finally wash the mixture repeatedly with deionized water, and dry to obtain a molten Polyetheretherketone resin with flow index of 14.7g / 10min.

[0059] The polyether ether ketone resin film obtained by the above process is added with inorganic fillers and organic compounds. The formula is: 93.6-91.6% polyether ether ketone, 0.2% inorganic filler nano-scale silica, 6.2% organic filler polyester resin; these substances are mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com