Mixed ionic liquid solution special for absorbing SO2 gas and preparation method thereof

A technology of ionic liquids and mixed ions, which is applied in separation methods, sulfur compounds, and dispersed particles, can solve problems such as poor thermal stability and oxidation resistance, loss of ionic liquids, and high preparation costs, so as to improve SO2 molar absorption The effect of reducing the amount of evaporation, reducing evaporation loss, and fast mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

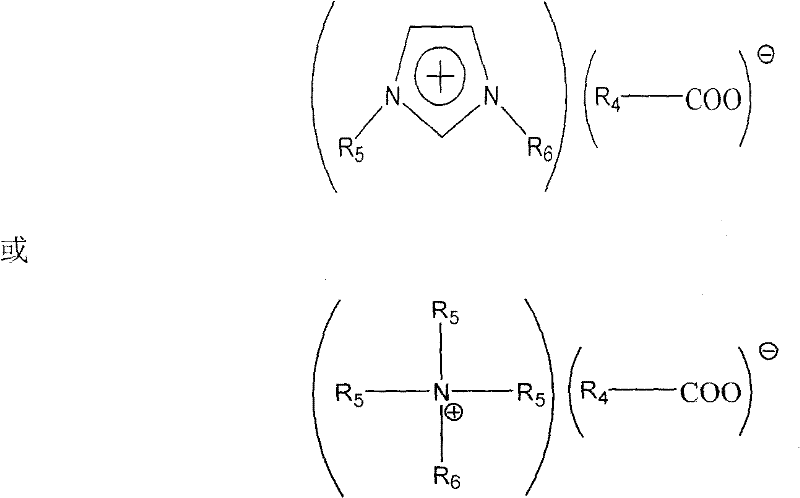

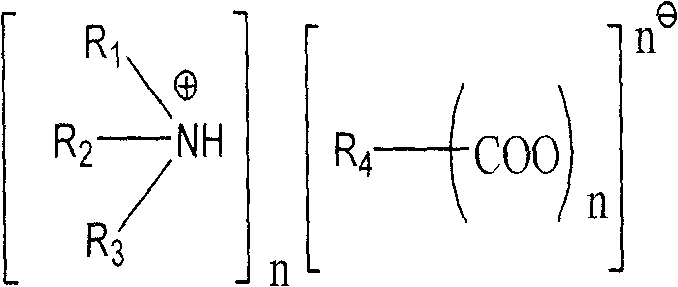

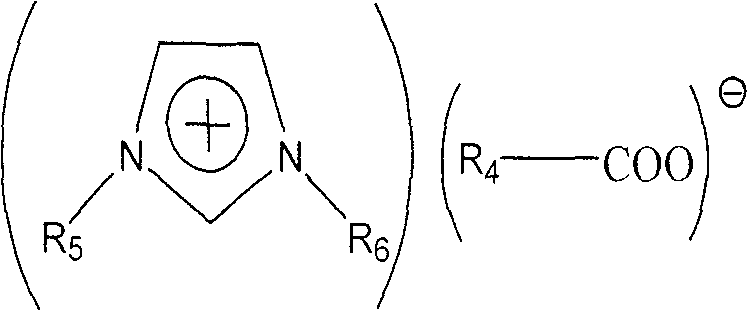

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: N, N'-methyl ethyl imidazole propionate and diethanolamine acetate mixed ionic liquid formula solution

[0023] Add 46g (0.25mol) of N,N'-methylethylimidazole propionate, 165g (1mol) of diethanolamine acetate, 90g of water, and 5g of polyethylene glycol ether (molecular weight: 200 to 400 ), propylene carbonate 4g, sulfolane 1g, stirred for 15 minutes and mixed uniformly to obtain a mixed ionic liquid solution of N,N-methylethylimidazole propionate and diethanolamine acetate.

Embodiment 2

[0024] Embodiment 2: N,-methylimidazole acetate and N,-methyldiethanolamine acetate mixed ionic liquid mixed ionic liquid solution

[0025] Add N'-methylimidazole acetate 14.2g (0.1mol), N'-methyldiethanolamine acetate 179g (1mol), water 175g, polyethylene glycol ether 8g (molecular weight is 200 ~400), propylene carbonate 4.1g, sulfolane 6g, stirred for 15 minutes and mixed uniformly to obtain a mixed ionic liquid solution of N'-methylimidazole acetate and N'-methyldiethanolamine acetate.

Embodiment 3

[0026] Embodiment 3: N, N'-methyl butyl imidazolium valerate and tripropylamine butyrate mixed ionic liquid solution

[0027] Add 24g (0.1mol) of N,N'-methylbutyl imidazolium valerate, 46.2g (0.2mol) of tripropylamine butyrate, 27.077g of water, 2g of propylene carbonate, and 1.009g of sulfolane into a 1L beaker, Stir for 15 minutes and mix well to obtain a mixed ionic liquid solution of N,N'-methyl butyl imidazolium valerate and tripropylamine butyrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com