Lithium ion battery and preparation method thereof

A lithium-ion battery and lithium salt technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of battery energy density, safety, cost, etc., and achieve excellent anti-overcharge performance and thermal stability High performance, fast charging and discharging, high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] According to the second aspect of the present invention, the preparation method for preparing the lithium-ion battery of the first aspect includes the steps of: dissolving the active material of the positive electrode, the conductive agent and the binder in the solvent and then stirring to form the positive electrode slurry; making the positive electrode slurry Coated on both sides of the aluminum foil of the current collector, after drying, rolling, and slicing, the positive electrode sheet was obtained; the active material, conductive agent and binder of the negative electrode were added to the stirring tank, vacuumed and stirred, and the solvent was added to continue stirring. Obtain the negative electrode slurry; apply the negative electrode slurry on both sides of the aluminum foil of the current collector, and obtain the negative electrode sheet after drying, rolling, and slicing; wind or laminate the obtained positive electrode sheet, negative electrode sheet and s...

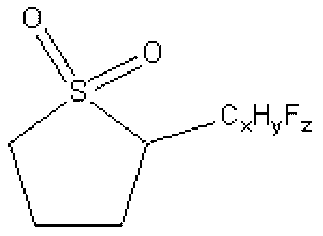

Embodiment 1

[0044] Preparation of High Pressure Fluorocarbonate Electrolyte: Weighing LiPF 6 Soluble in fluoroethylene carbonate (FEC) and ethyl methyl carbonate (EMC) (FEC / EMC volume ratio is 1:1). Prepare 1Mol / L LiPF 6 solution, adding 0.5% by mass percentage of 2-fluoroethyl sulfolane C 6 h 11 FSO 2 (In general formula 1, x=2, y=4, z=1), stir evenly to obtain high pressure resistant fluorocarbonate electrolyte.

[0045] Positive sheet preparation: according to the mass ratio, 94% of the positive active material 0.5Li 2 MnO 3 0.5LiNi 0.5 mn 0.5 o 2 , 2% of SP (super conductive carbon black), 1% of graphite conductive agent KS-6 and 3% of PVDF (polyvinylidene fluoride) dissolved in NMP (N-methylpyrrolidone) and stirred to make positive electrode slurry; The positive electrode slurry is coated on both sides of the aluminum foil with a density of 340g / m 2 , through drying, rolling and slicing to obtain the positive electrode sheet;

[0046] Negative electrode sheet preparation: ...

Embodiment 2

[0050] The difference from Example 1: the positive electrode active material is 0.3Li 2 MnO 3 0.7LiNi 0.5 mn 0.5 o 2 , the surface density after coating is 333g / m 2 , the formation process charges the battery to 3.0V.

[0051] After testing, the soft pack battery obtained in Example 2 has a capacity of 786mAh, an internal resistance of 54mΩ, an open circuit voltage of 3.2V, an energy density of 153Wh / L, and a capacity retention rate of 94% after 500 cycles. The battery did not catch fire or explode during the short-circuit safety test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Internal resistance | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com