Method for thinning grapheme layer by layer

A multi-layer graphene and graphene technology, applied in the field of two-dimensional material graphene, to achieve the effect of maintaining high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: bilayer graphene is thinned into monolayer graphene

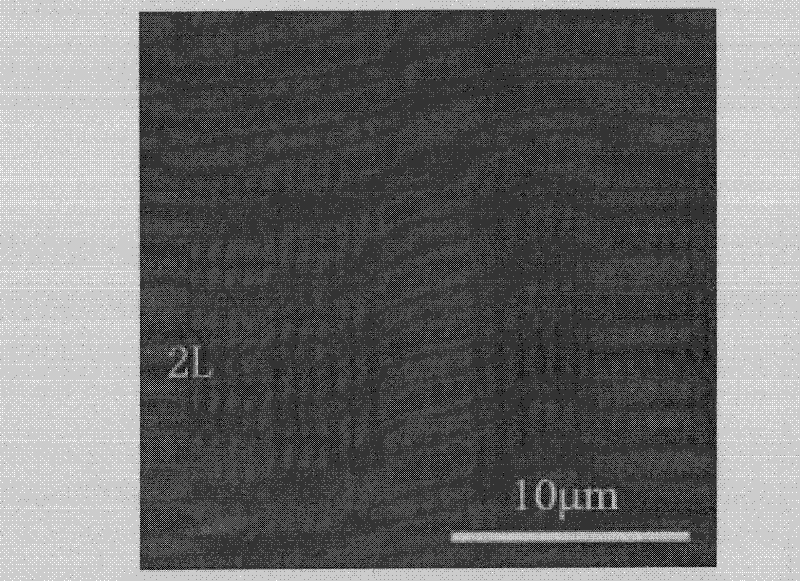

[0031] First of all, using aggregated graphite as raw material, in SiO 2 / Si substrate mechanical exfoliation to obtain bilayer graphene samples, in figure 1 Marked as 2L.

[0032] Plasma treatment process: put the sample into the cavity of the plasma asher, select the gas source as nitrogen, the gas flow rate as 100ml / min, the temperature as room temperature, the air pressure: 0.3mbar, and plasma bombardment for 10 seconds to obtain the damage of the top layer. bilayer graphene.

[0033] Annealing and thinning process: put the above-mentioned graphene sample into a tube furnace, and feed a high-purity argon flow of 200ml / min, and the furnace will heat up to 900°C within two hours; at this temperature, 5ml / min o 2 / Ar mixed gas for 5 minutes, and finally the tube furnace was naturally cooled to room temperature. Oxygen content in mixed gas 0.05wt%

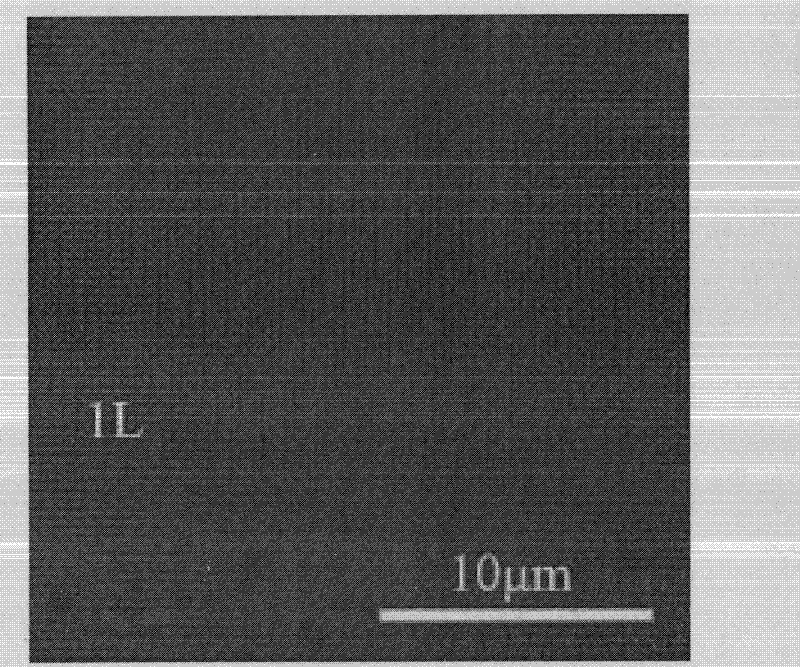

[0034] Through the above process, double-layer g...

Embodiment 2

[0035] Embodiment 2: three-layer graphene is thinned into double-layer graphene

[0036]First of all, using aggregated graphite as raw material, in SiO 2 / Si substrate mechanically exfoliated to obtain a three-layer graphene sample ( Figure 5 ).

[0037] First thinning:

[0038] The first plasma treatment process: put the sample into the cavity of the plasma asher, select the gas source as nitrogen, the gas flow rate as 200ml / min, the temperature as room temperature, the air pressure: 0.5mbar, and plasma bombardment for 15 seconds to obtain Three-layer graphene with damaged top layer.

[0039] The first annealing process: put the above-mentioned graphene sample into a tube furnace, and pass a high-purity argon flow of 200ml / min, and the furnace will heat up to 1000°C within two hours; at this temperature, pass 5ml / minO 2 / Ar mixed gas (wherein the oxygen content is 0.05wt%) for 10 minutes, and finally the tube furnace is naturally cooled to room temperature. Achieve th...

Embodiment 3

[0044] Embodiment 3: Two-layer graphene is thinned into double-layer graphene

[0045] Preparation of two-layer graphene: use metal copper foil as a substrate, grow at 1000° C., methane and hydrogen flow rate 50 sccm: 100 sccm, and normal pressure for 5 minutes to obtain double-layer graphene. Removing the copper foil substrate to transfer bilayer graphene to SiO 2 / Si substrate.

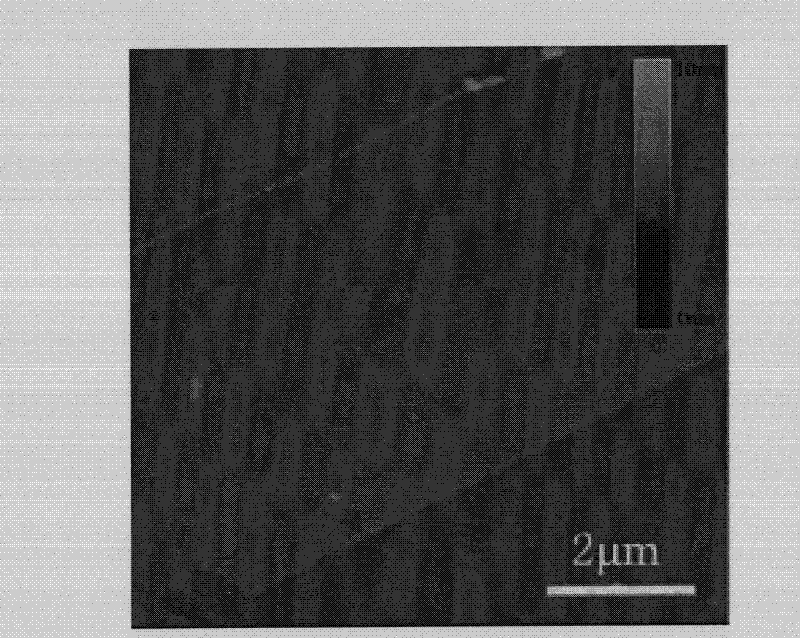

[0046] By the same plasma treatment and annealing thinning process as in Example 2, the double-layer graphene is thinned into a single layer, and the Raman result is the same as that in Example 1. Figure 4 similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com