Geometrical variable flame stabilizing device

A flame stabilization and variable technology, applied in combustion methods, combustion chambers, combustion equipment, etc., can solve the problems of unable to maintain flame stabilization performance and flow resistance loss, unable to optimize combustion flame stabilization performance and flow resistance loss, etc. Less, more achievable and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

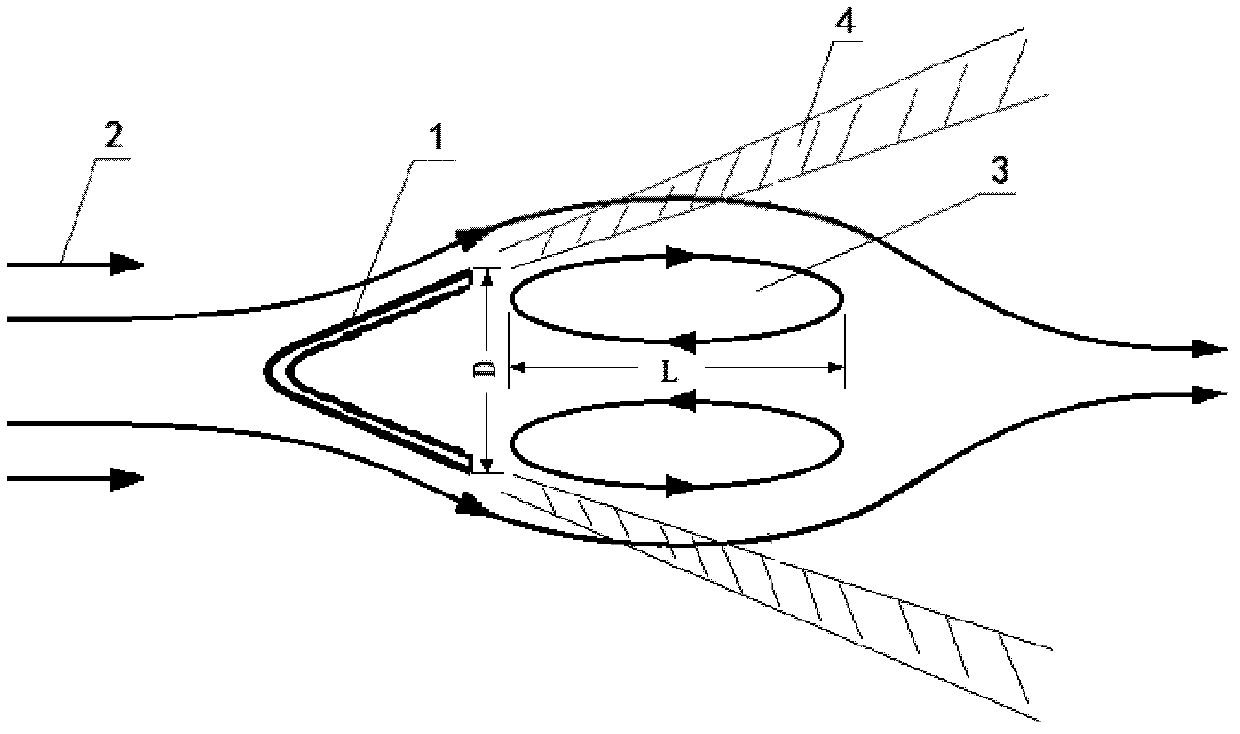

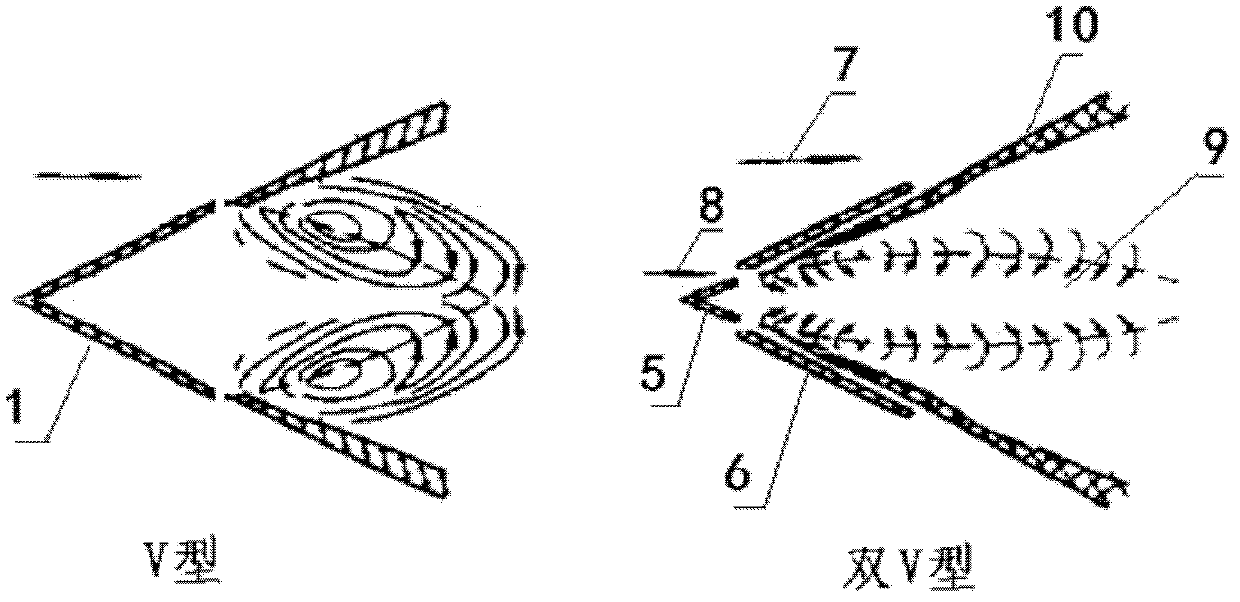

[0029] The geometric variable flame stabilization device provided by the present invention, such as Figure 4 , Figure 5 shown, specifically:

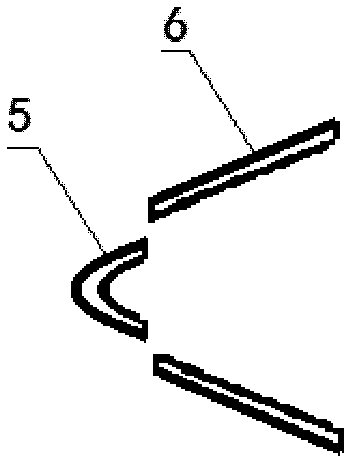

[0030] The geometrically variable flame stabilization device provided by the present invention takes a V-shape as a basic bluff body structure, and is composed of a stabilizer main body part and a transmission power part. The main part of the stabilizer is as Figure 4 As shown, it includes a front streamlined head 11, a rear movable blade A12 with a rotating shaft 16A, a rear movable blade B13 with a rotating shaft 17B, a rotating shaft support plate 14 and a mounting seat 15. Both ends of the streamlined head 11 are fixedly connected to the mounting seat 15. and the shaft support plate 14. The two ends of the rotating shaft A16 and the rotating shaft B17 respectively pass through the mounting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com