Gasifier and Incinerator for Biomass Sludge Destruction

a biomass sludge and gasifier technology, applied in the field of gasifiers, can solve the problems increasing the cost of gasification, so as to achieve the effect of increasing the cross-sectional area of the afterburner chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086]The novel features which are believed to be characteristic of the present invention, as to its structure, organization, use and method of operation, together with further objectives and advantages thereof, will be better understood from the following discussion.

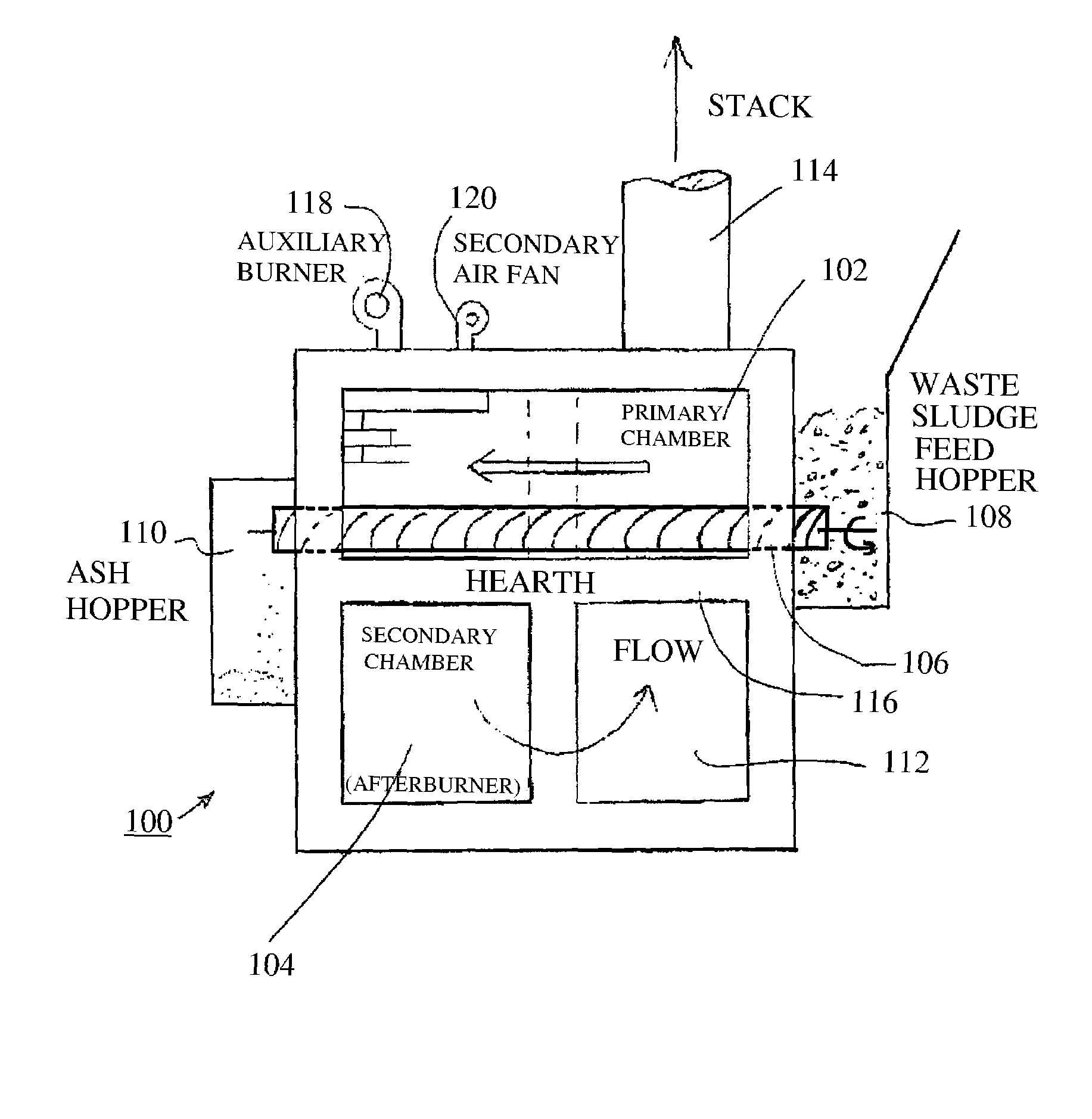

[0087]Turning first to FIGS. 5 and 6, simplified views of a biomass sludge gasifier and incinerator in keeping with the present invention are shown. The biomass sludge gasifier and incinerator is identified generally with the numeral 100, and comprises a primary chamber 102, a secondary chamber or afterburner chamber 104, and at least one primary auger 106. Biomass sludge is fed into the biomass sludge gasifier and incinerator 100 from a sludge feed hopper 108 so as to be carried across the primary chamber 102 by the at least one primary auger 106, with the resulting incinerated ash being collected in an ash hopper 110.

[0088]The biomass sludge which is intended to be gasified and incinerated in keeping with the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com