Friction stirring-welding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

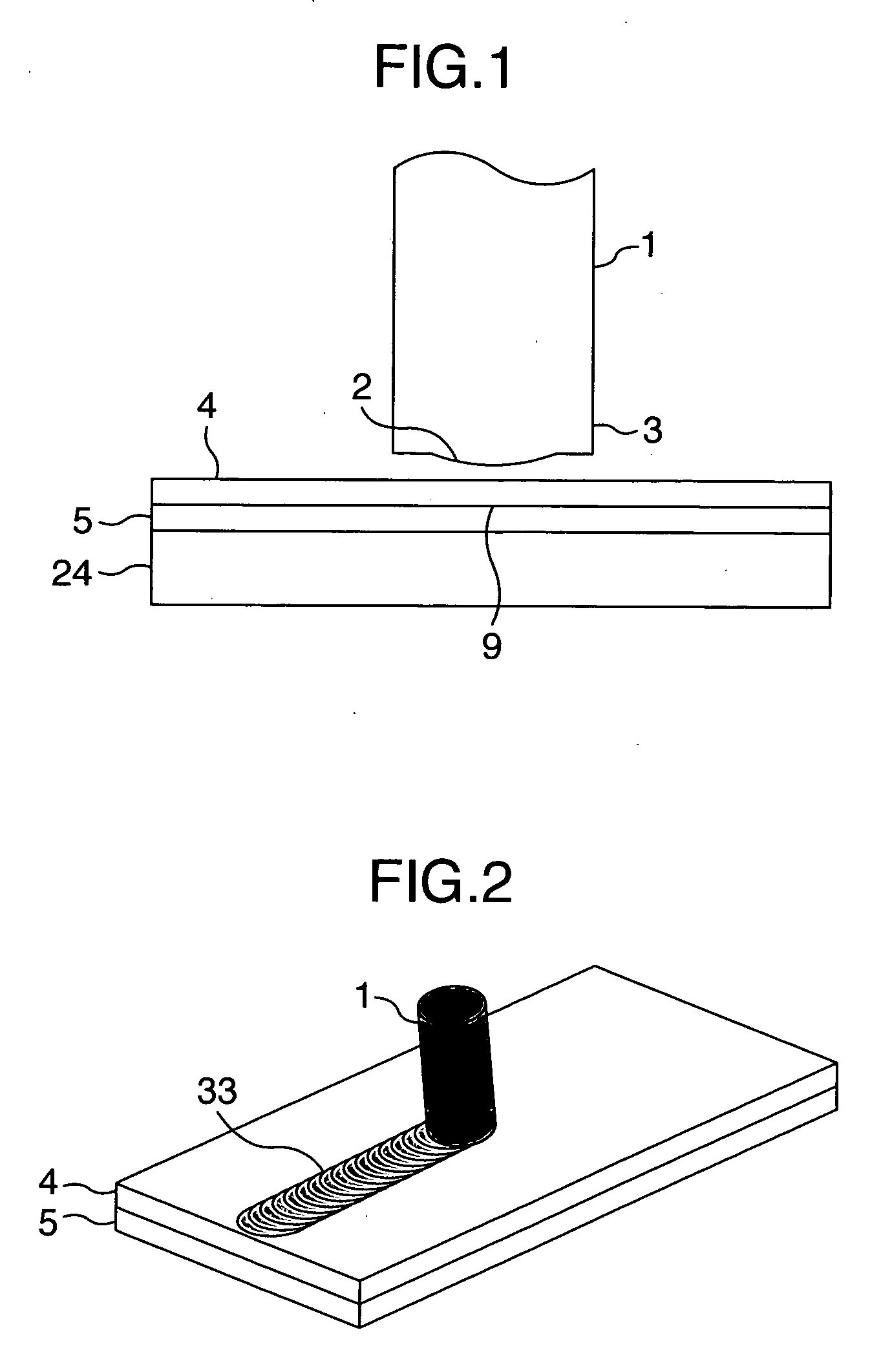

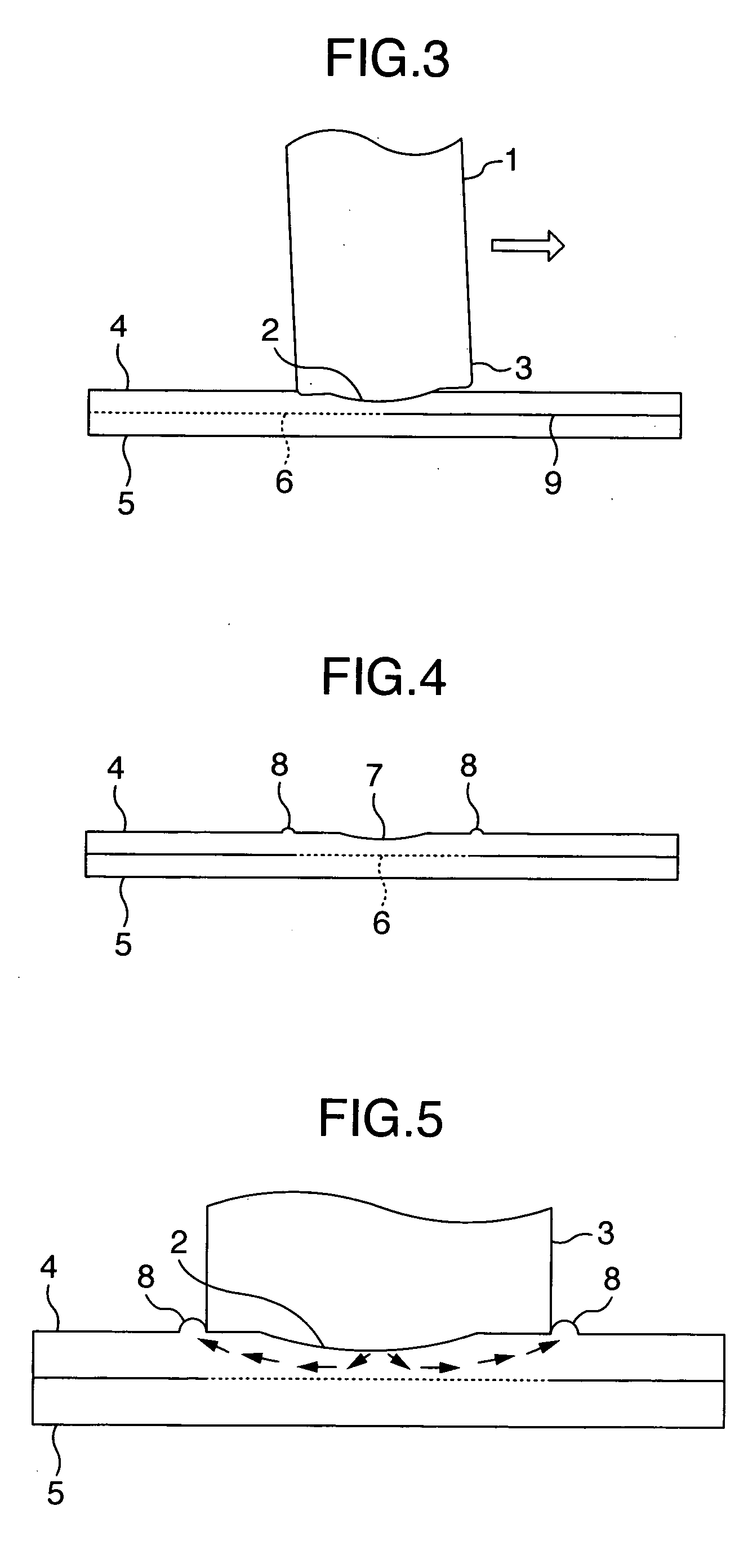

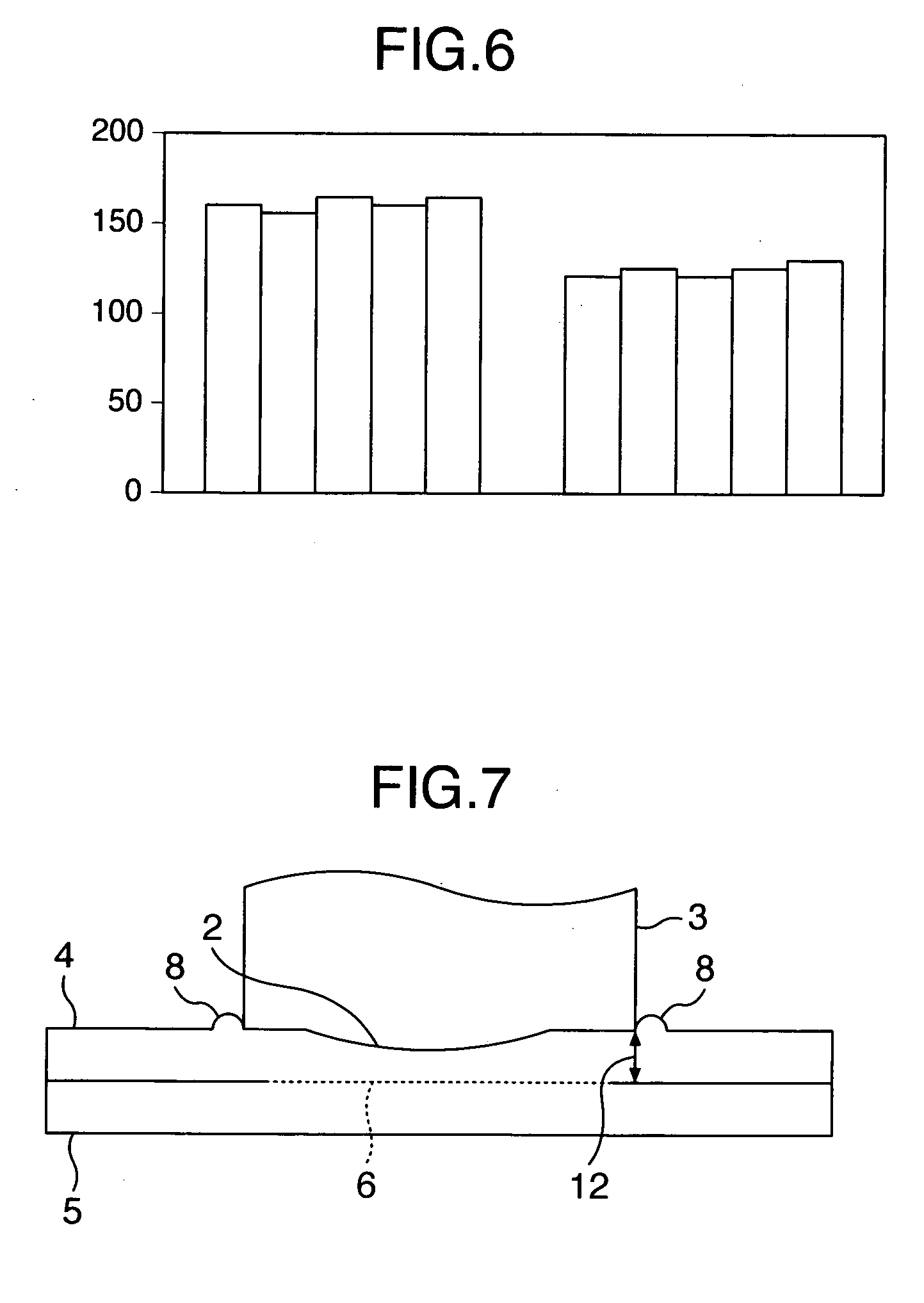

[0037]FIG. 1 is a cross sectional view showing a first embodiment. A welding tool 1 comprises a small diameter projected part 2 at the tip end of a large diameter shoulder 3. A welding test piece comprises an upper plate 4 and a lower plate 5, which lap each other and are arranged on a bearing member 24. FIG. 2 is a perspective view in the course of welding. By rotating and moving the welding tool 1 in a direction of welding in a state, in which it is pressed only into the upper plate 4 from a side of the upper plate 4, welding boundary surfaces 6 of the upper plate 4 and the lower plate 5 can be welded to each other. An indentation 7 is produced on the upper plate 4 as the welding tool 1 is moved. FIG. 3 is a cross sectional view showing a direction of welding in the course of welding. An axis of rotation of the welding tool 1 in the course of welding is inclined on an opposite side to a direction of welding indicated by an arrow, that is, a backward angle side. FIG. 4 is a cross s...

second embodiment

[0046]FIG. 11 is a cross sectional view showing a state before welding in a second embodiment. The embodiment differs from the first embodiment in that a trapezoidal member 30 is provided on a welding part of an upper plate 4 to make the upper plate 4 thick. FIG. 12 is a cross sectional view showing the welded part in the second embodiment. While an indentation 7 is produced on the welded part, any indentation does not remain and a flat surface is obtained when the welded part is ground flat.

third embodiment

[0047]FIG. 13 is a cross sectional view showing a state before welding in a third embodiment. FIG. 14 is a cross sectional view showing a welded part. The embodiment differs from the first embodiment in that a groove 32 is provided on an upper plate 4 and a projected part 31 is provided on a lower plate 5 to be fitted into the groove. Thereby, since the welding part can be made smaller in thickness than the upper plate 4, it is possible to perform welding for a further large plate thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com