Composite cosine tooth form internal meshing transmission gear

A technology of transmission gears and internal gears, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of unstable transmission, short service life, large vibration and noise, etc., and achieve stable power transmission , Strong bearing capacity, the effect of avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the compound cosine-toothed internal meshing transmission gear of the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

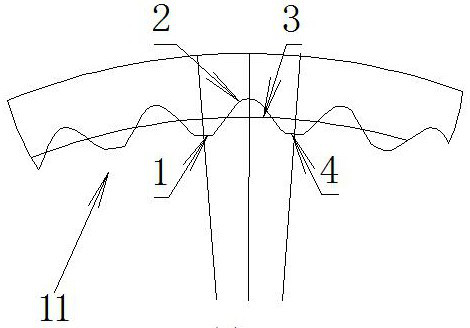

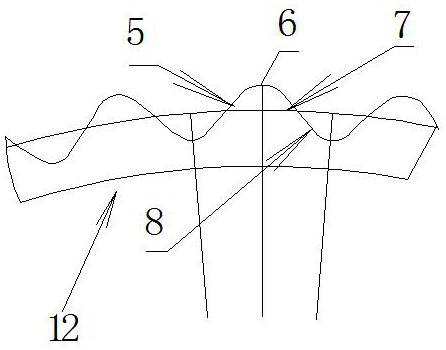

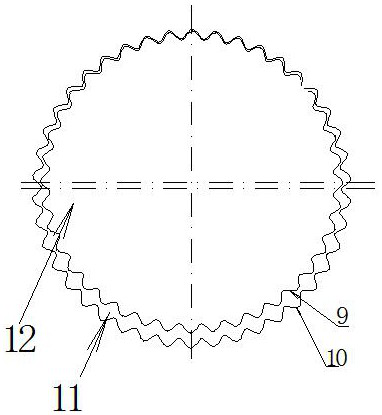

[0018] The purpose of the present invention is that the technical solution is achieved in this way, the compound cosine tooth-shaped internal meshing transmission gear includes an internal gear 11 and an external gear 12, the internal gear is surrounded by a plurality of internal teeth, and the external gear is surrounded by multiple The profile of the adjacent internal teeth of the internal gear close to the tooth crest is the main body profile of the internal tooth, and the profile of the adjacent external teeth of the external gear close to the tooth valley is the main body profile of the external tooth, which is characterized in that: The profile of the main body of the internal tooth is a cosine curve segment, and the cosine curve segment at this end is the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com