Toothed chain with optimised chain joint and increased external flank angle

A technology of tooth surface angle and tooth chain, which is applied in the field of tooth chain to achieve the effect of increasing the hinge surface and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

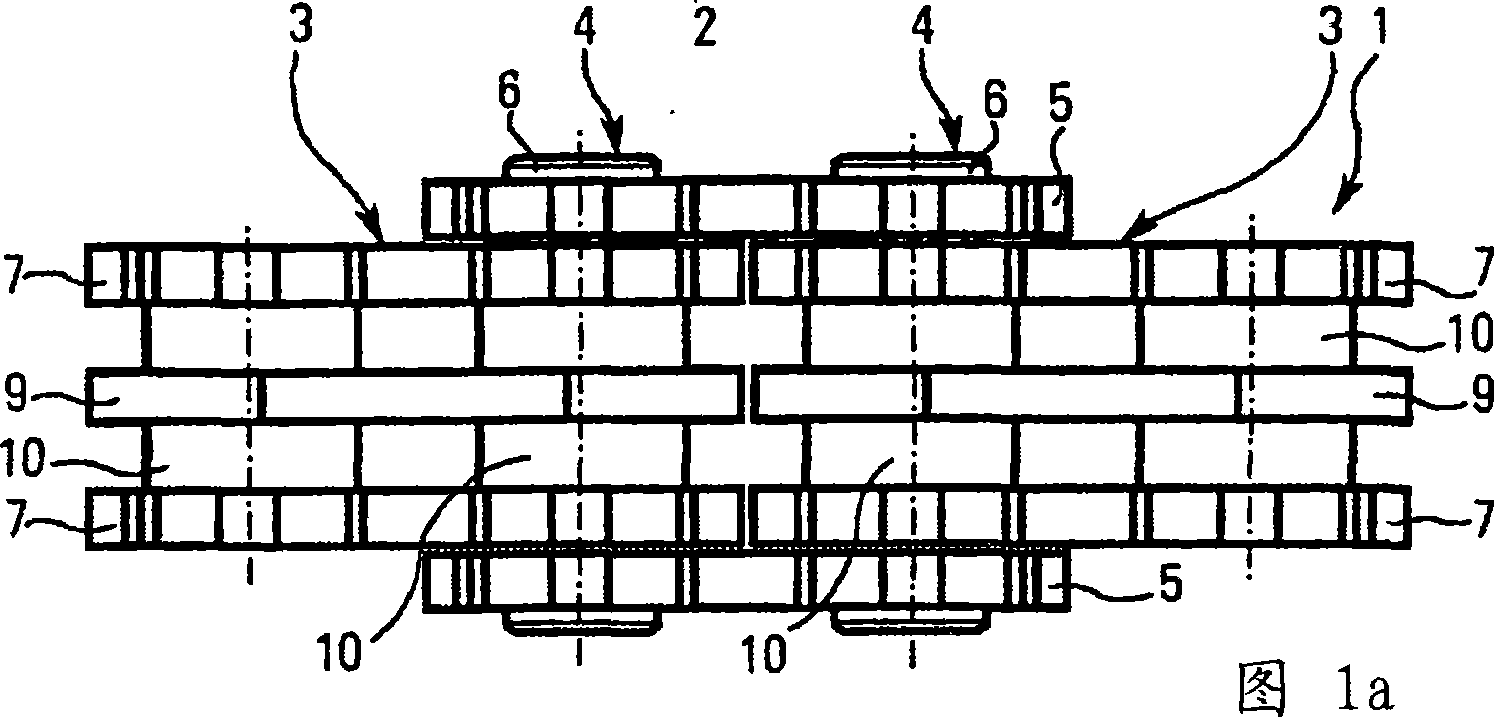

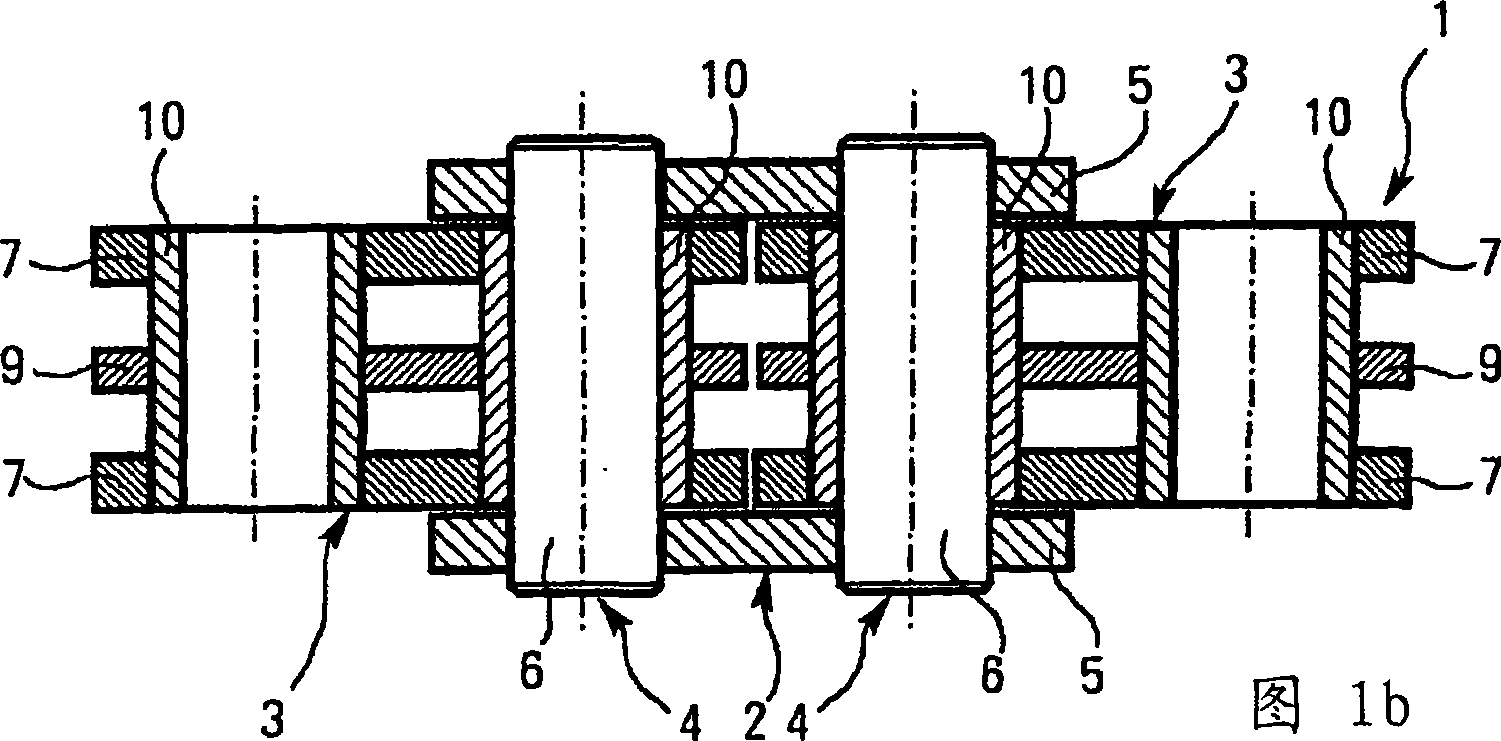

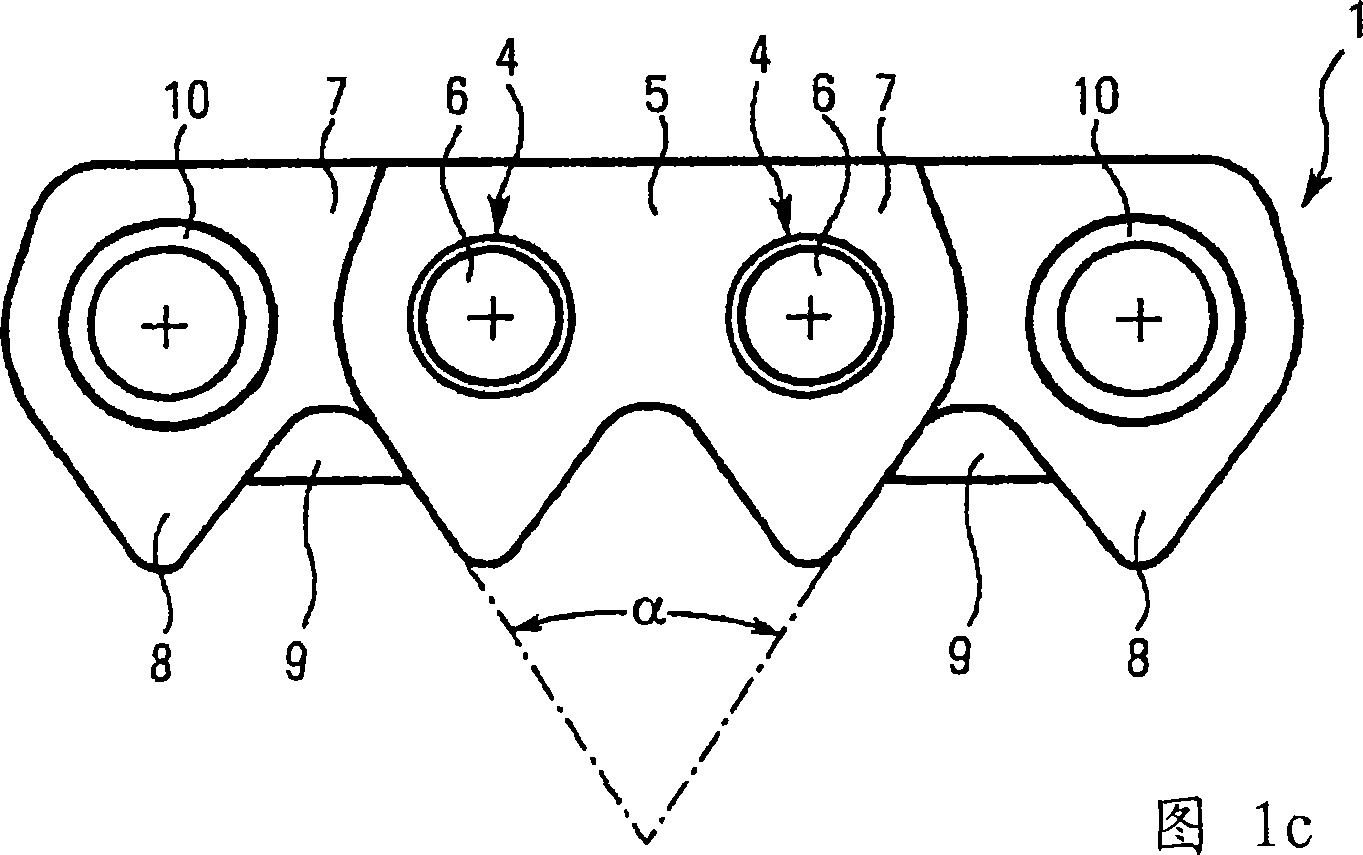

[0034] The toothed chain 1 according to the invention shown in FIG. 1 comprises outer chain links 2 and inner chain links 3 arranged alternately with one another, which are connected to one another via links 4 . The outer chain links 2 each consist of outer chain plates 5 arranged on the outside and extending parallel to one another, with holes aligned with each other, into which a respective hinge pin 6 is pressed or riveted.

[0035]The inner chain links 3 are positioned between the outer chain plates 5 of the outer chain links 2 and each comprise two chain plates 7 which are arranged facing each other parallel to the outer chain plates 5 . In this case, the link plates 7 are directed in an offset manner towards the outer link plates 5 located on the outside. Furthermore, the inner chain link 3 includes a guide plate 9 and two joint sleeves 10 in each case. Here, the guide plate 9 is arranged in the center of the inner link 3 , while the two link plates 7 are arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com