Straightness detection device for geological exploration drill rod

A technology for geological exploration and detection devices, which is applied to measurement devices, optical devices, workpiece clamping devices, etc., can solve problems such as low detection efficiency, poor detection accuracy, and inability to detect inclination, and improve detection efficiency and detection range. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

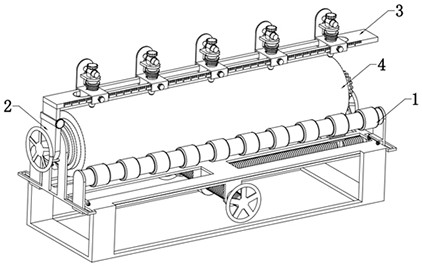

[0041] like Figure 1 to Figure 10 As shown, a straightness detection device for a drill pipe for geological exploration includes a support assembly 1, a clamping assembly 2, a detection assembly 3 and a drill pipe body 4. The clamping assembly 2 is arranged on both ends of the upper surface of the support assembly 1, and the clamping assembly 2 The top of the holding assembly 2 is provided with a detection assembly 3 , and the middle of the upper surface of the supporting assembly 1 is provided with a drill rod body 4 , which is clamped by the clamping assembly 2 .

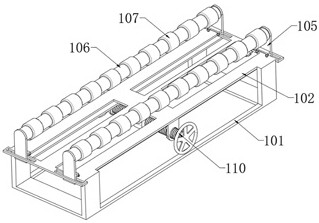

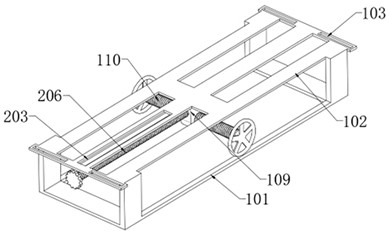

[0042] Support assembly 1, the support assembly 1 includes a support frame 101, the upper surface of the support frame 101 is provided with a support frame 102, the four corners of the support frame 102 are provided with through grooves 103, the through grooves 103 are arranged in a strip structure, and the support frame 102 The lower surface of the movable plate 104 is provided with two symmetrically distributed...

no. 2 example

[0055] like Figure 11 As shown, when the drill pipe body 4 is inspected, especially if the position of the drill pipe body 4 is convex or concave, the vertical support rod 106 and the elastic roller 107 cannot have the required supporting effect on the drill pipe body 4 At the same time, when the drill rod body 4 is rotated to detect the straightness, the convex or concave position of the drill rod body 4 is limited to the support rod 106 and the elastic roller 107, so that it cannot be further rotated and calibrated. In order to solve the above problems, The straightness detection device for a drill pipe for geological exploration further includes: a controller is provided on one side of the support assembly 1 , the controller is mainly arranged on one side of the support frame 101 , and the controller electrically controls each electrical element.

[0056] The light transmittance of the light-transmitting lens 316 gradually decreases from top to bottom, and the other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com