Driving device and electric tool applying same

A technology for driving devices and power tools, applied in power tools, transmission devices, gear transmission devices, etc., can solve the problems of limiting the reduction ratio of the gearbox and increasing the volume of the gearbox.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

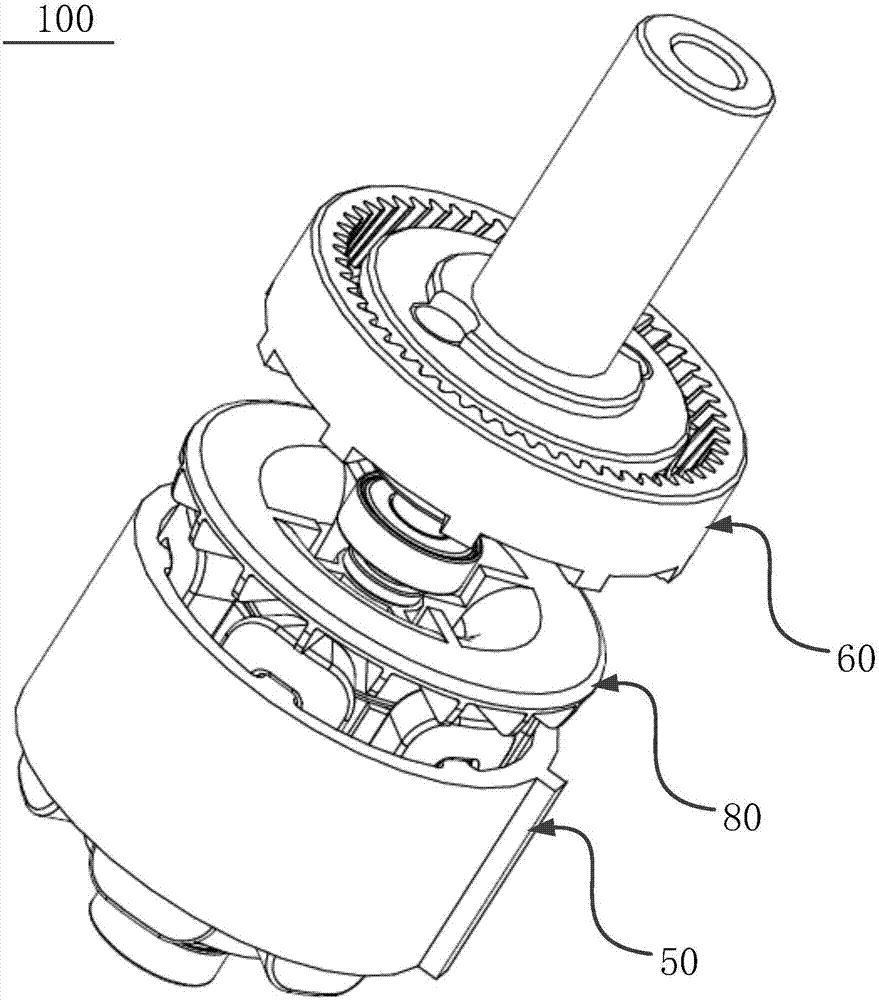

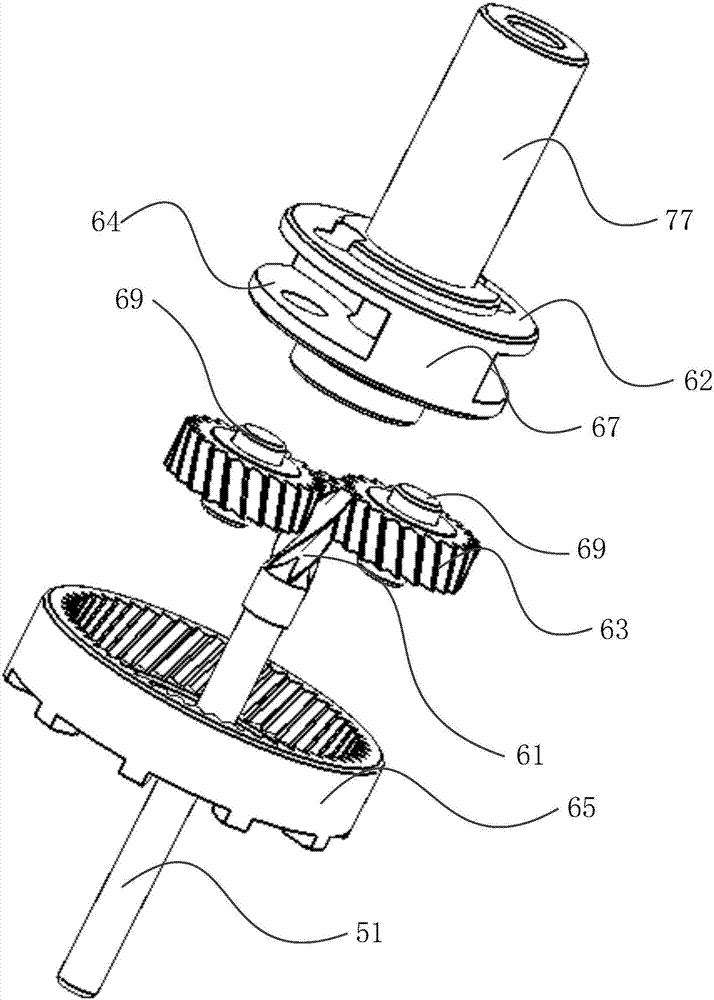

[0030] Such as figure 1 As shown, the present invention provides a driving device 100 including a motor 50 and a planetary gearbox 60 . The gear box 60 is installed on the output end of the motor 50, decelerates the output of the motor 50 and then outputs it to the outside.

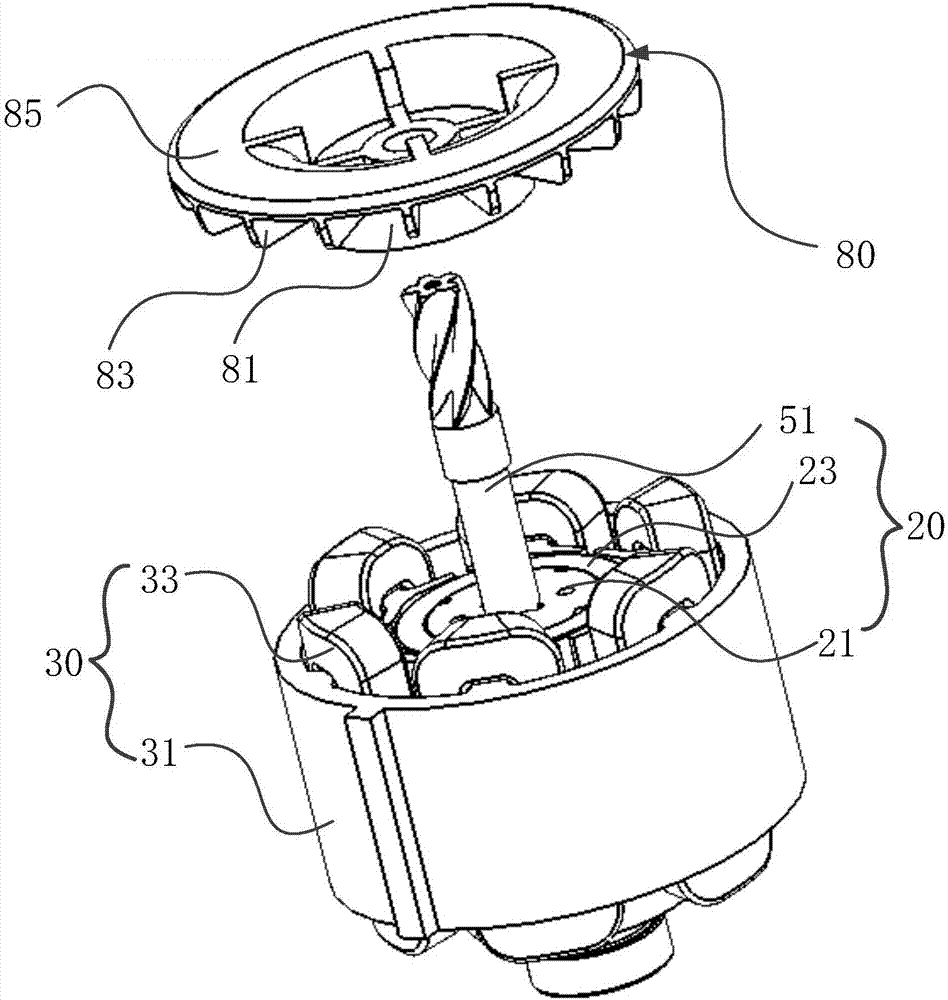

[0031] Such as Figure 1 to Figure 2 As shown, the motor 50 includes a stator 30 and a rotor 20 , and the stator 30 includes a stator core 31 and a winding 33 wound on the stator core 31 . The stator core 31 includes an annular yoke and a plurality of teeth protruding inward from the yoke. Winding slots are formed between adjacent teeth, and windings 33 are wound on the teeth. The rotor 20 includes a rotating shaft 51 , a rotor core 21 fixed to the rotating shaft 51 , a permanent magnet 23 mounted to the rotor core 21 , and the like. There is a gap between the teeth of the rotor core 23 and the stator core 31 , allowing the rotor 20 to rotate relative to the stator 30 . In this embodiment, the stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com