Driving rear axle of mini electric vehicle

A technology for electric vehicles and rear axles, which is applied to vehicle components, control devices, transportation and packaging, etc. It can solve the problems of small internal space, insufficiently compact structure and low transmission efficiency of mini electric vehicles, and improve the internal space Insufficient, saving raw materials, and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

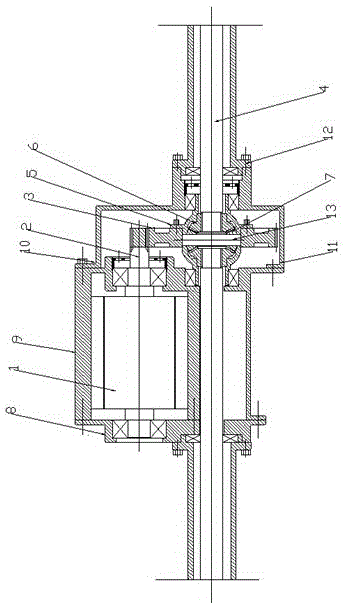

[0014] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: a miniature electric vehicle drives the rear axle, including a motor (1), a motor output gear shaft (2), a primary driven gear (3), and left and right driving half shafts (4) , the primary driven gear (3) is arranged under the motor output gear shaft (2), the primary driven gear (3) is connected to the differential case (5) through bolts, and the left and right driving half shafts ( 4) Located on both sides of the primary driven gear (3), fixed by the differential case (5), the left and right drive axle shafts (4) are connected to the planetary gear (7) through the axle gear (6), The side gear (6) is fixed inside the differential case (5).

[0015] The motor (1) is connected with an engine front end cover (8) and an engine rear end cover (9), and the engine rear end cover (9) is connected with a first-stage reduction box (10) through bolts, and the reduction box (10 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com