Co-location differential speed reducer

A technology of differential reduction and reducer, which is applied in the direction of differential transmission, transmission, belt/chain/gear, etc. It can solve the problems of inconvenient manufacturing and maintenance of gears, hindering performance, complex structure of planetary reducer, etc., and achieve The effect of enriching the transmission ratio selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

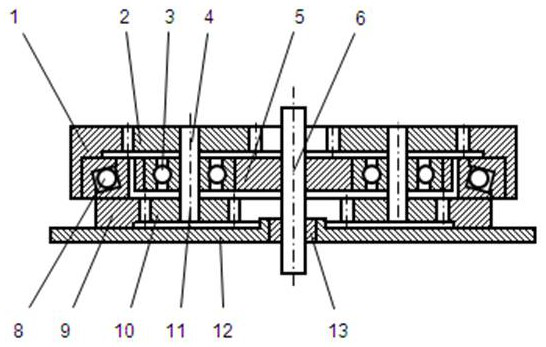

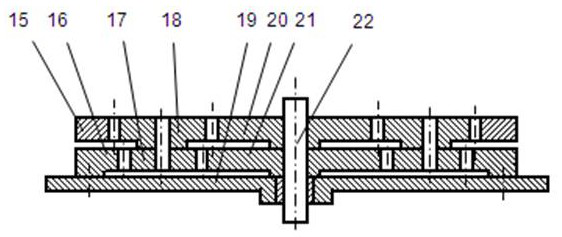

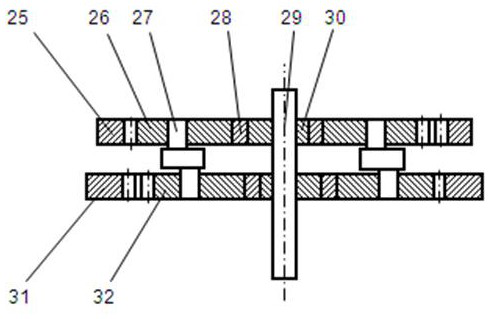

[0027]The transmission wheel of the present invention comprises a co-position differential gear train; a co-position differential gear train of a basic structure has two co-position transmission wheel sets, and the transmission wheels of each other correspond to a co-position group, and the two transmission wheels of one group can be Synchronous rotation, revolution, parallel rotation or simultaneous rotation and revolution, the co-location group is called a synchronous group, and the other group of transmission wheels that are paired with it has coaxial or parallel shafts, one of which is fixedly installed as a stator, and the other rotationally installed as a stator. Rotor, the co-location group is called differential group; the synchronous group and the differential group are directly transmitted or driven through the intermediate wheel; the co-located differential gear train uses the synchronous group as the input element and the rotor as the output element for deceleration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com