Large displacement high pressure gear pump with driving and driven wheels in different sizes

A technology of different sizes and driven wheels, applied in the direction of rotary piston type/swing piston type pump parts, pumps, pump components, etc. The effect of force deformation, reduction of internal leakage, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

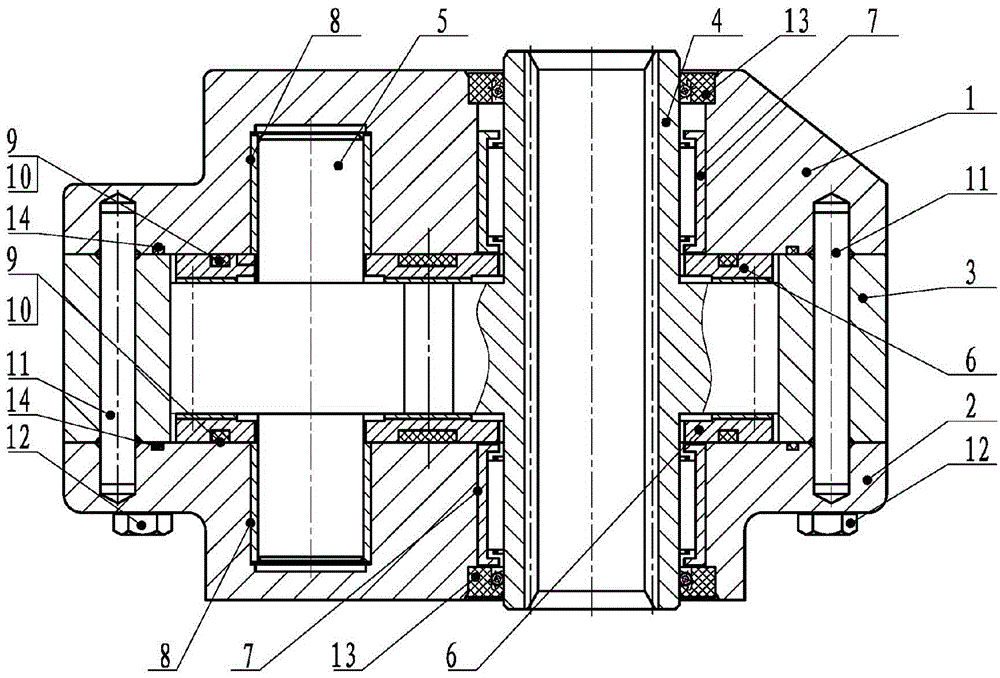

[0017] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

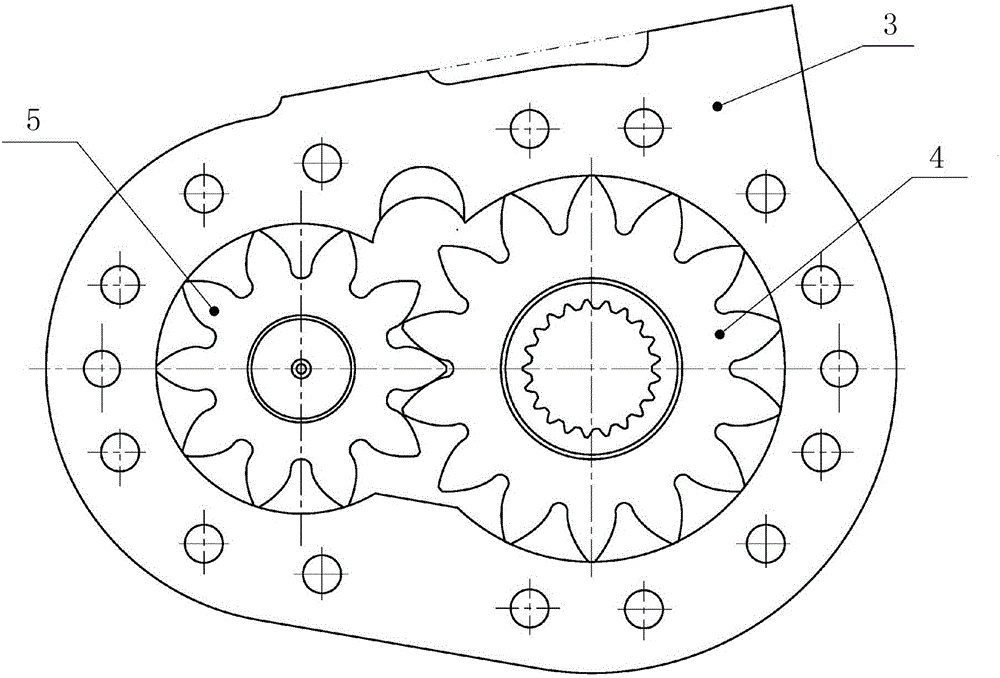

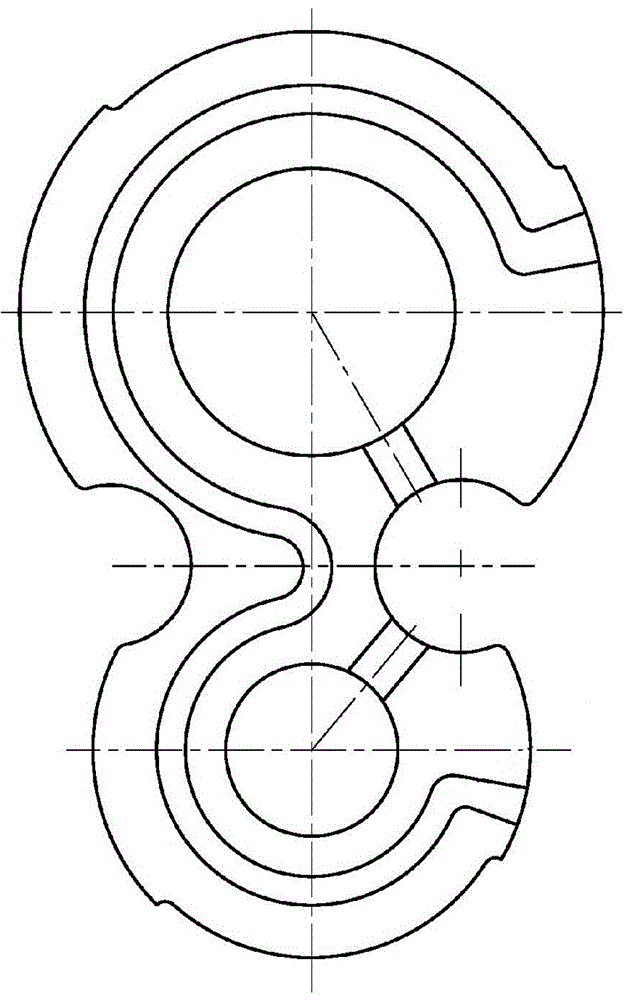

[0018] Such as Figure 1~3 As shown, the present invention includes a pump body 3, a front cover 1 and a rear cover 2 connected to the pump body 3, a pair of gear pairs with different sizes of driving and driven wheels, and two symmetrical floating side plates 6. Among them, there are two roller bearings 7 at the 4 places of the driving wheel, two DU bearings 8 at the 5 places of the driven wheel, a set of E-shaped sealing rings 9 on the back of the floating side plate 6, the pump body 3 and the front cover 1, the pump body 3 and the An outer sealing ring is respectively arranged between the rear covers 2, and the outer sealing ring adopts an O-shaped sealing ring 14 .

[0019] Such as figure 2 As shown, a pair of gear pairs with the same modulus and unequal number of teeth is smaller in size and lighter in weight, and the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com