Locking force adjustable separated full-contact bearing support special for constant-velocity universal joint assembly

A constant velocity universal joint and bearing support technology, which is applied to the rigid support of bearing components, bearing elements, shafts and bearings, etc., can solve the problems of high manufacturing cost, difficult part processing, and vehicle use requirements, and achieve improved Rationality and reliability, improving the radial force state, and eliminating the effect of over-tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

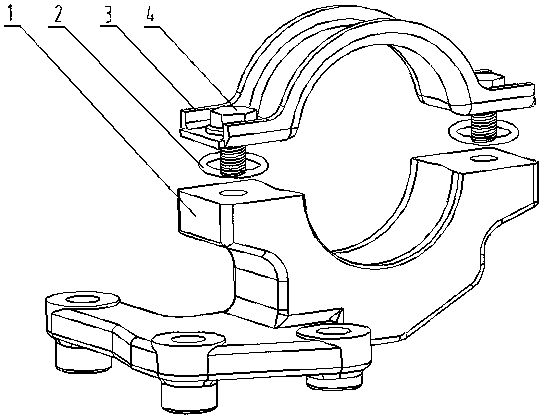

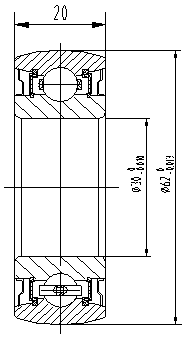

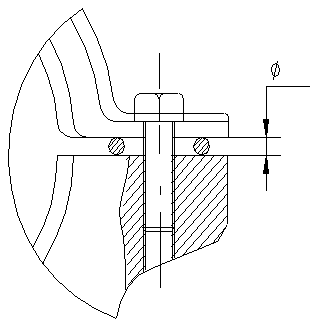

[0023] Embodiment 1 of the present invention such as Figure 1 to Figure 5 shown. The separable full-contact bearing support with adjustable locking force is composed of a bearing support 1, an upper gland 3, two silicone rubber O-rings 2 and two fastening flange screws 4. Wherein, two silicone rubber O-rings 2 are respectively located on two mating surfaces between the upper gland 3 and the bearing support 1 . The size and specification of the two silicone rubber O-rings 2 are the same. The cross-sectional thickness of the original state of the silicone rubber O-ring 2 is diameter φ=2.5-4.0mm. reasonably certain. The assembled section thickness of the silicone rubber O-ring 2 is 30% to 70% of the original section thickness. The bearing support 1 is made of cast aluminum material, and the grade of the cast aluminum material is generally A38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com