Multi-planet-wheel transmission mechanism

A technology of transmission mechanism and planetary gear, which is applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of insignificant effect of the weight of the gearbox, limit the transmission ratio of the planetary gear train, reduce the weight of the gearbox, etc., to achieve The effect of compact structure, increased transmission ratio, and increased uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

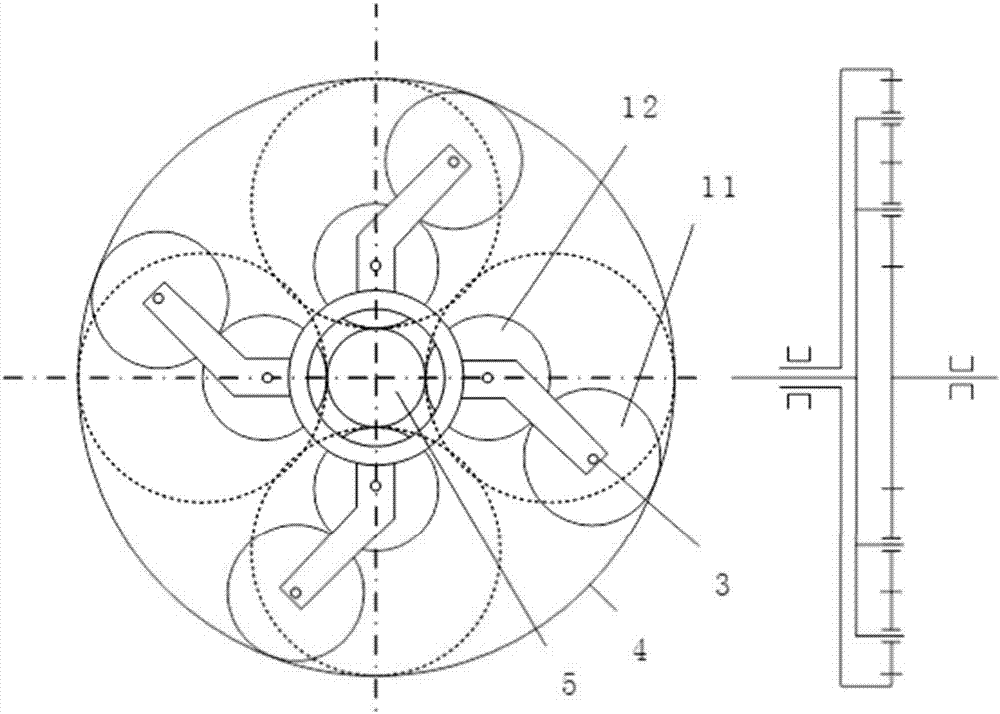

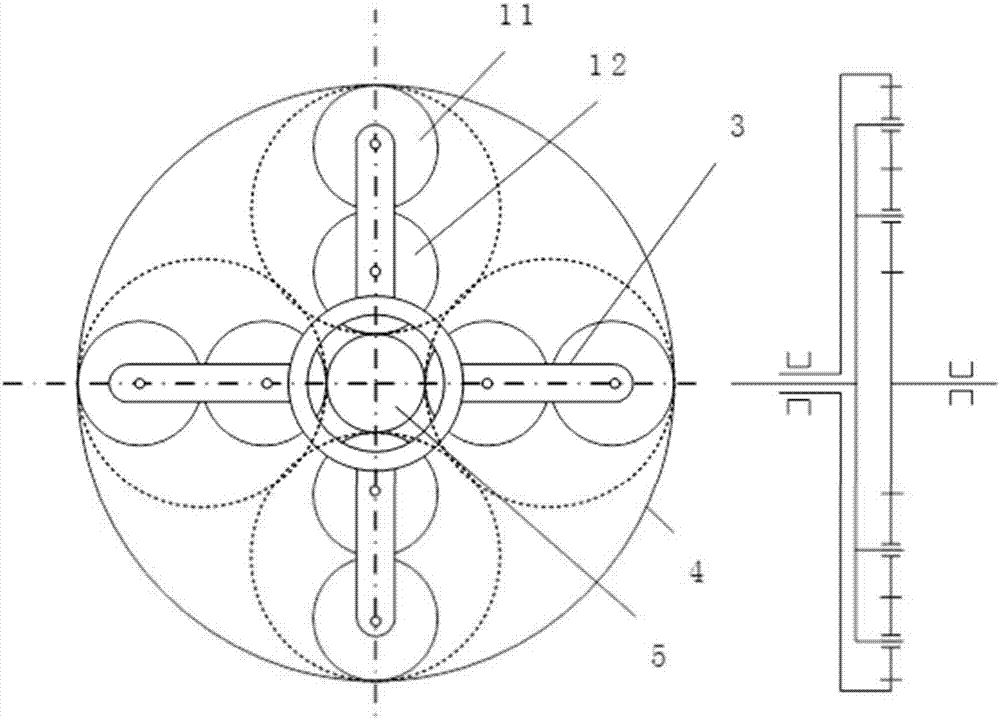

[0038] see figure 1 and figure 2 , the multi-planet gear transmission mechanism of the embodiment of the present invention comprises sun gear 5, planetary carrier 3, ring gear 4 and 4 planetary gear sets, and planetary gear set is made up of two gears (first gear 11 and second gear 12), The first gear 11 and the second gear 12 are mounted on the planet carrier 3 and can rotate freely relative to the planet carrier 3. The first gear 11 meshes with the ring gear 4 and the second gear 12 respectively, and the second gear 12 meshes with the sun gear 5 respectively. Mesh with the first gear 11. The number of teeth of the sun gear 5 is z s , the number of teeth of ring gear 4 is z r , the number of teeth of the first gear 11 is z p1 , the number of teeth of the second gear 12 is z p2 , figure 1 The number of teeth of the first gear 11 and the second gear 12 is greater than the number of teeth of the original planetary gear, figure 2 The sum of the number of teeth of the fir...

Embodiment 2

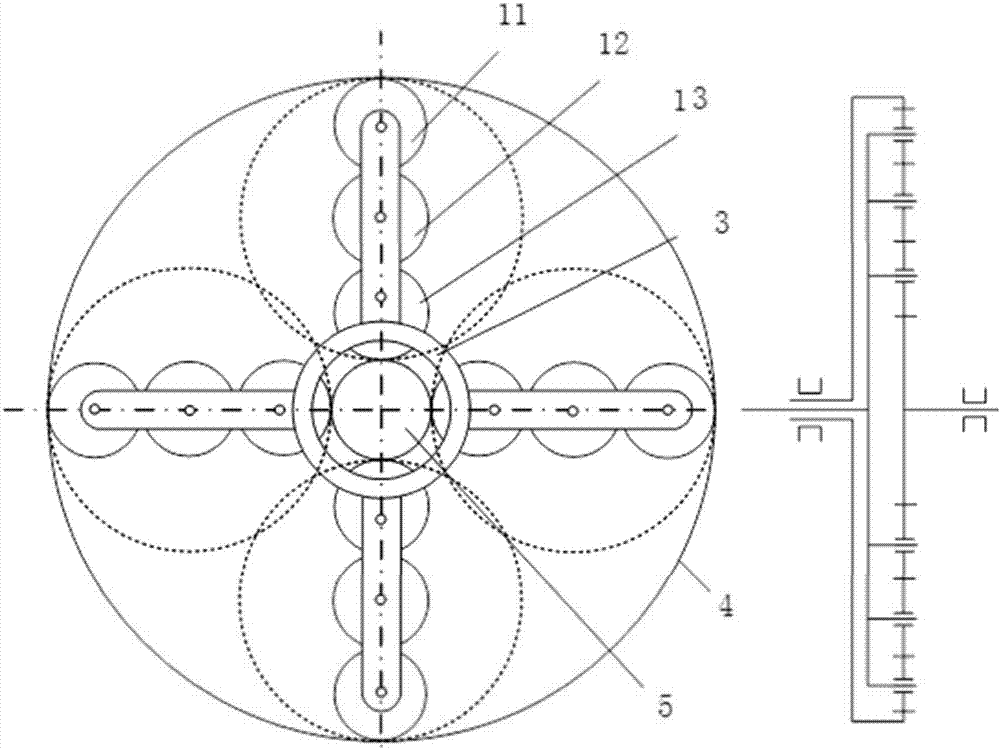

[0049] see image 3 , the multi-planet gear transmission mechanism of the embodiment of the present invention comprises sun gear 5, ring gear 4, planetary carrier 3 and 4 planetary gear sets, and planetary gear set consists of 3 gears (the first gear 11, the second gear 12 and the first gear Three gears 13) are composed of three gears mounted on the planet carrier 3 and can rotate freely relative to the planet carrier 3. The first gear 11 meshes with the ring gear 4 and the second gear 12 respectively, and the second gear 12 meshes with the first gear respectively. 11. The third gear 13 meshes, and the third gear 3 meshes with the sun gear 5 and the second gear 12 respectively. The number of teeth of the sun gear 5 is z s , the number of teeth of ring gear 4 is z r , the number of teeth of the first gear 11 is z p1 , the number of teeth of the second gear 12 is z p2 , the number of teeth of the third gear 13 is z p3 , the sum of the number of teeth of the first gear 11, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com