Rotary land leveler operating device based on short-tooth shape

A working device, rotary technology, applied in the direction of earthmoving machine/shovel, construction, etc., can solve the requirement of continuous and smooth motion of pinion meshing with rotary ring gear, difficult to guarantee, slow rotation speed of rotary ring gear, and worm gear. Worm fatigue damage and other problems, to achieve the effect of compact structure, improved reliability and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further illustrated below by means of embodiments in conjunction with the accompanying drawings.

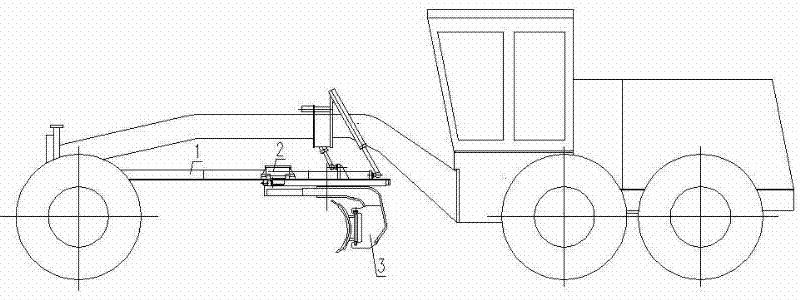

[0041] figure 1 It is the outline drawing of the rotary grader. The working device of the rotary grader is composed of a traction frame 1, a rotary mechanism 2 and a blade body assembly 3.

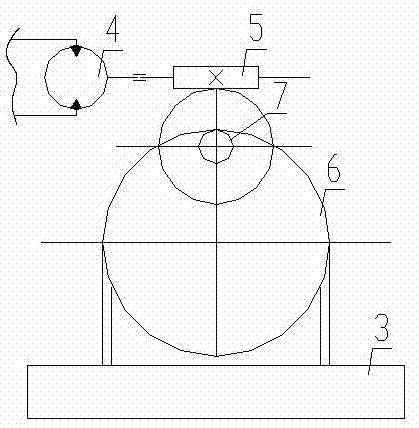

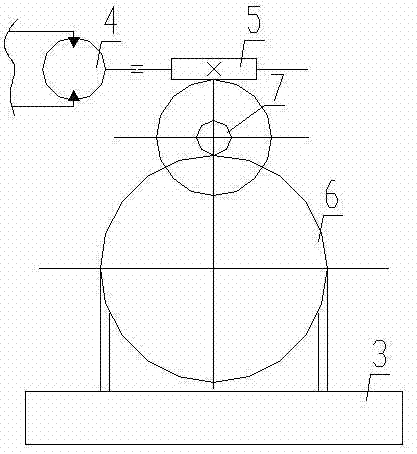

[0042] figure 2 , image 3 They are the internal meshing transmission schematic diagram and the external meshing transmission schematic diagram of the slewing mechanism of the motor grader respectively. The slewing mechanism of the motor grader is composed of a hydraulic motor 4 , a worm gear reducer 5 , and a slewing ring gear 6 . Wherein, the hydraulic motor 4 and the worm gear reducer 5 form an integral body, and are fixed on the traction frame 1 with bolts. The output torque of the hydraulic motor 4 is decelerated by the worm gear reducer 5 to realize deceleration and torque increase. The coaxial pinion 7 is installed on the worm gear, and the pinion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com