High-speed transmission correcting gear

A technology for correcting gears and high-speed transmission. It is applied to belts/chains/gears, components with teeth, portable lifting devices, etc., which can solve the problems of increasing the size and weight of the transmission gear pair, and the transmission structure is not compact enough to achieve improvement. Meshing conditions, improving strength and transmission efficiency, reducing wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

Examples:

When K=1 is selected, the pinion adopts the correction method of adding 1 to the number of teeth, and its geometric elements are as follows:

1.1 Index circle diameter d 1 =mZ 1

1.2 Pitch circle diameter d t1 =m(Z 1 +1)

1.3 Base circle diameter d 01 =mZ 1 cos20°

1.4 Base section t 0 =mπcos 20°

1.9 Pinion root circle diameter d i1 =(Z 1 +2ξ 1 -2.5)m

1.6 Z 1 ,Z 2 The actual meshing angle of the two gears a,

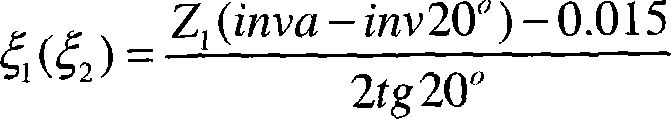

1.7 Z 1 ,Z 2 When the meshing gap between the two gears is 0.03m, the correction coefficient of the small gear and the large gear is

1.8 Full height of small gear teeth (full height of large gear teeth) h 1 (h 2 )=m[2.25-(ξ 1 -0.5)]

1.9 Pinion root circle diameter d i1 =(Z 1 +2ξ 1 -2.5)m

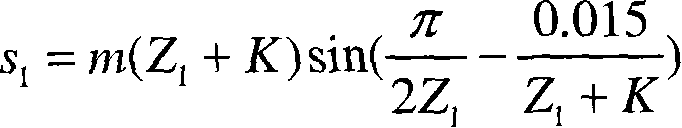

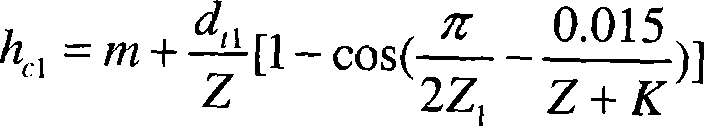

1.10 Fixed chord tooth thickness s 1 = m ( Z 1 + 1 ) sin ( π 2 Z ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com