Variable-speed flywheel

A flywheel and tower wheel technology, applied in the field of variable speed flywheels, can solve the problems of increased cost of flywheel components and inability to assemble, and achieve the effect of increasing the speed ratio range and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

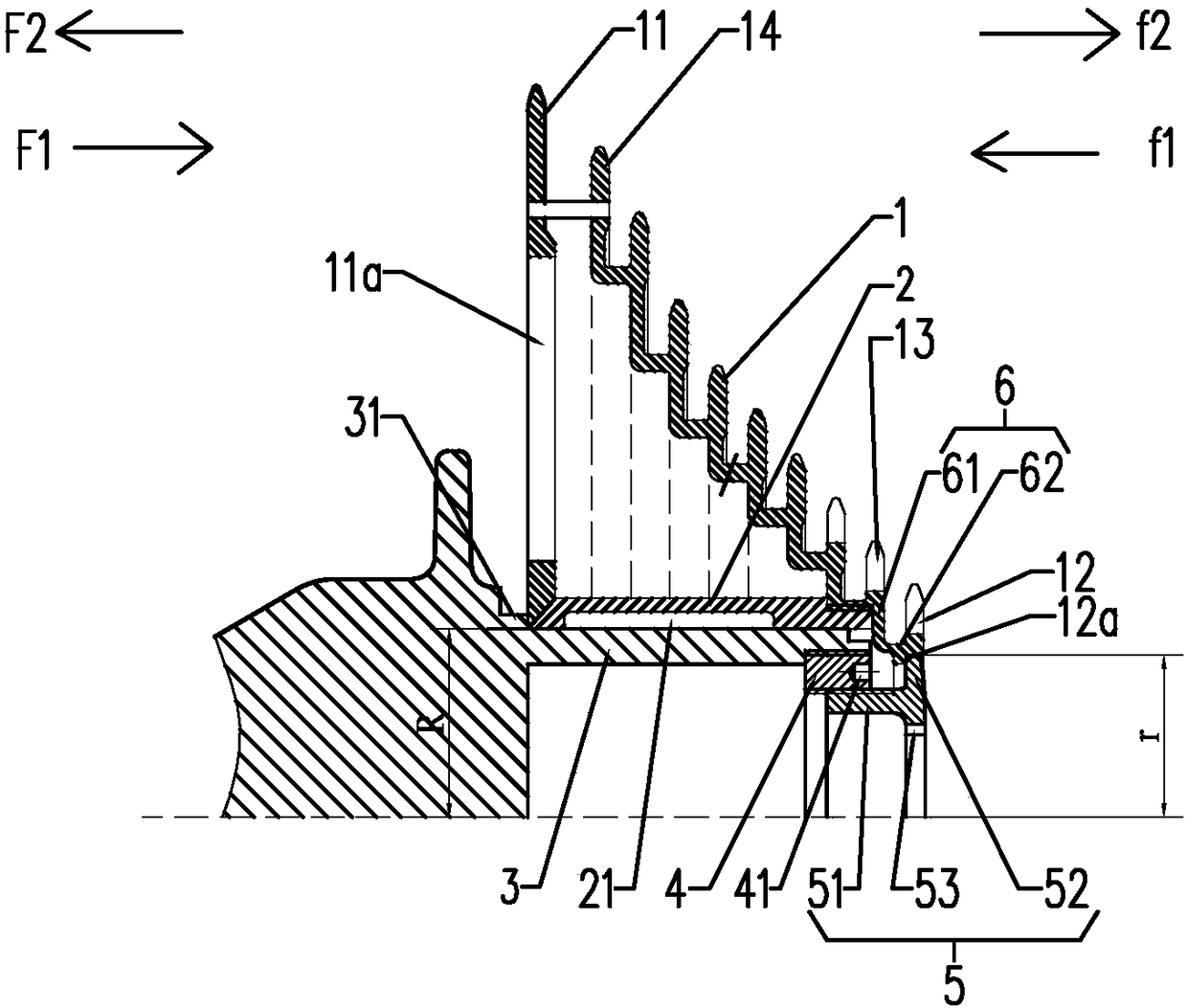

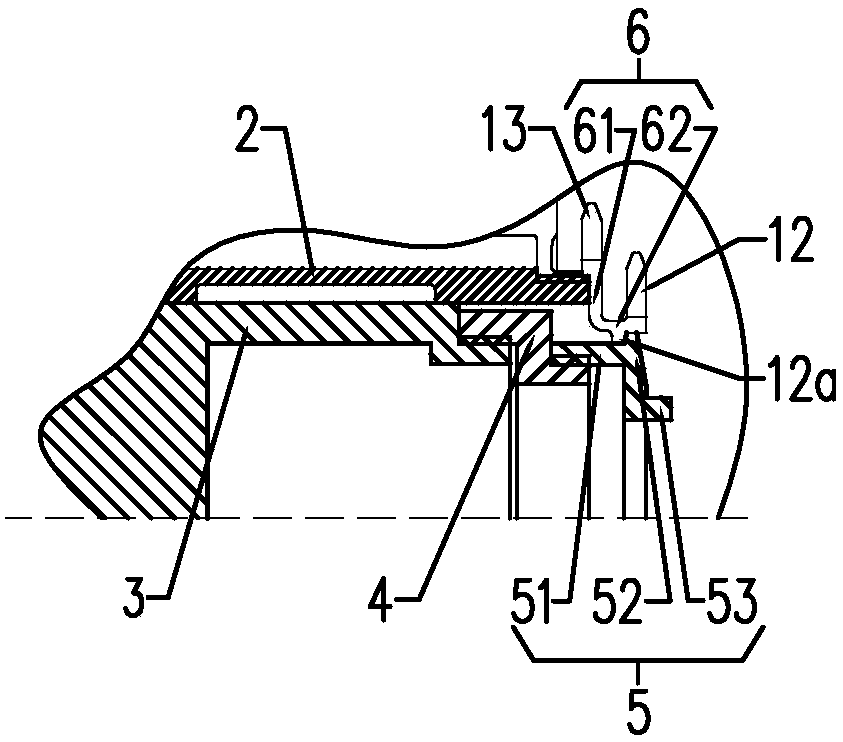

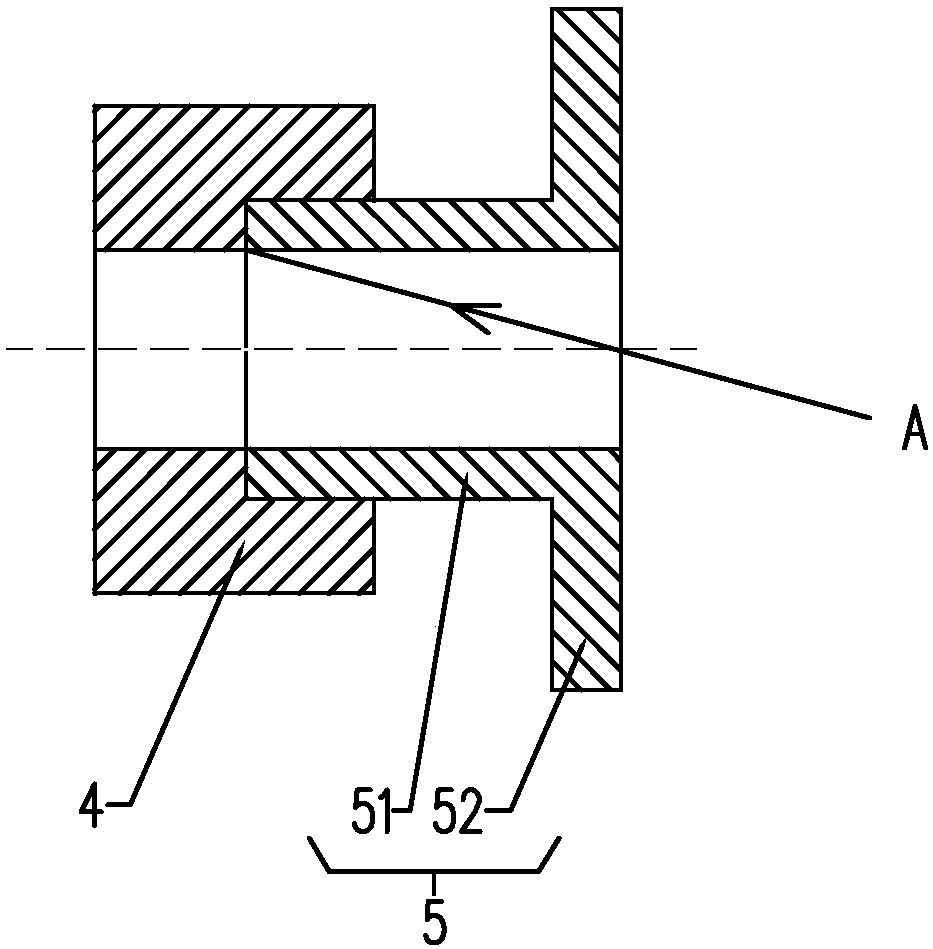

[0021] Such as figure 1 As shown, a variable speed flywheel includes a cone wheel 1, a hub 2, a hub 3, a connecting ring 4 and a ring end cover 5, which are overlapped by multi-layer ring gears with successively increasing diameters. The cone wheel 1 includes the largest diameter The first ring gear 11 and the second ring gear 12 with the smallest diameter, the cone wheel 1 is in transmission connection with the hub 2, for example, the two ends of the hub 2 can be respectively connected with the first ring gear 11 and the second ring gear 12 to form a stable The triangular structure makes the flywheel have good stability and high strength. The hub 3 is connected with the hub 2 to form a circumferential transmission, such as a key connection, with a simple structure and stable transmission; the inner diameter 2r of the second ring gear 12 can be smaller than the outer diameter 2R of the hub 3, so that it is convenient to design according to the second ring gear 12 The diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com