Biological radical polyatomic alcohol prepared by Jatropha curcas oil

A bio-based polyol and jatropha oil technology, applied in hydrolysis preparation, organic chemistry and other directions, can solve the problems of poor performance, complex process, high cost of raw materials, and achieve the effects of high degree of reaction, high product conversion rate and convenient purchase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

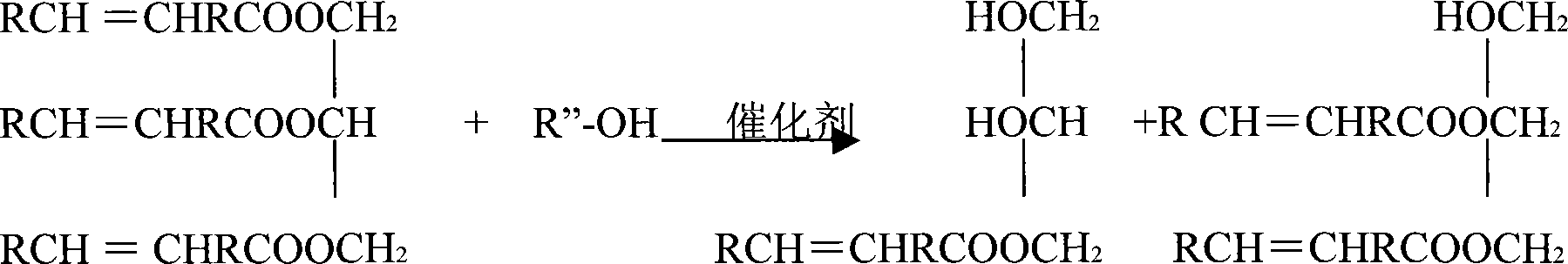

[0051] Add 1000g of jatropha oil, 215g of glycerin, and 1.0g of potassium hydroxide into a 2L glass kettle, stir, raise the temperature to 160-240°C, carry out the alcoholysis reaction for 5 hours, and then keep it under the condition of vacuum degree of 100-750kPa 3h. Refining then, obtains 1185g of mixed fatty acid ester.

Embodiment 2

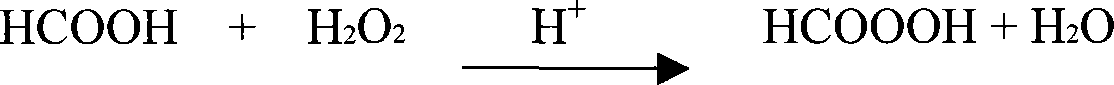

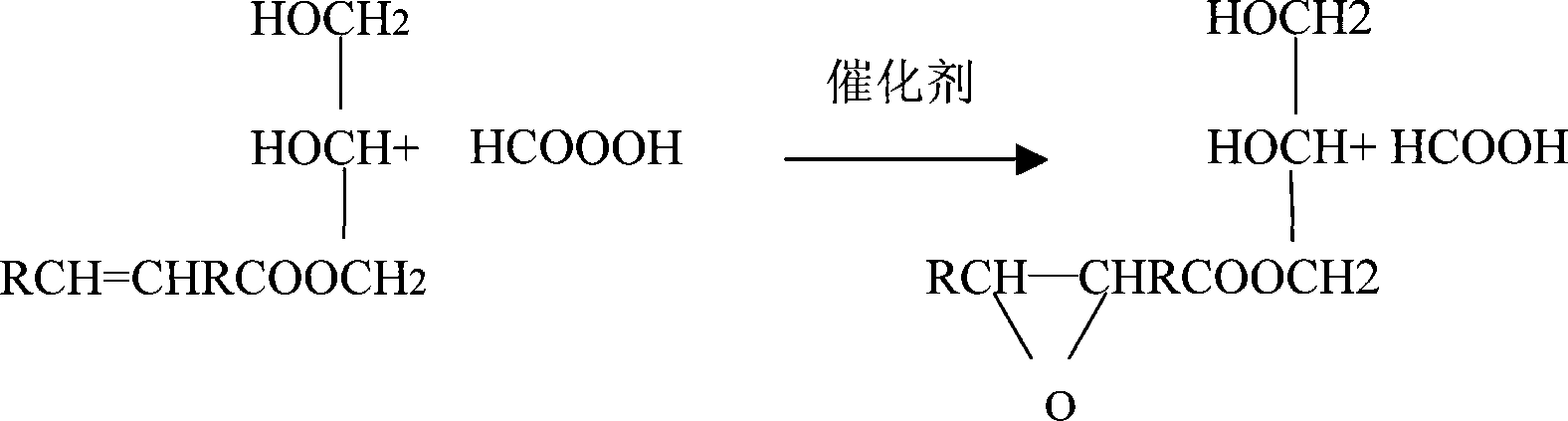

[0053]Take 1000 g of mixed fatty acid ester in Example 1, add 74 g of formic acid (85%), and 20 g of phosphoric acid into a 2L glass kettle, stir, add 507 g of hydrogen peroxide (27.5%) dropwise, and react for 8 hours at 30-70°C , After refining, a mixed epoxy fatty acid ester was obtained with an epoxy value of 3.41%.

Embodiment 3

[0055] Mix the product in Example 2 with 1000 g of epoxy fatty acid ester, then add 380 g of triethanolamine and 1.2 g of potassium hydroxide, add it into a 2L glass kettle, stir and raise the temperature, control the reaction temperature at 120-160°C, and the reaction time is 6h. After refining, 1280g of the bio-based polyol A product was obtained, the hydroxyl value was 490mgKOH / g, and the water content was ≤0.10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com