Polarizing plate and liquid crystal display employing the same

a technology of liquid crystal display and polarizing plate, which is applied in the direction of polarizing elements, instruments, transportation and packaging, etc., can solve the problems of reducing the productivity or manufacturing cost of the product, the viewing angle is small, and the thickness cannot be increased, so as to reduce the dimensional change (shape change), the effect of excellent optical properties and simple constitution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

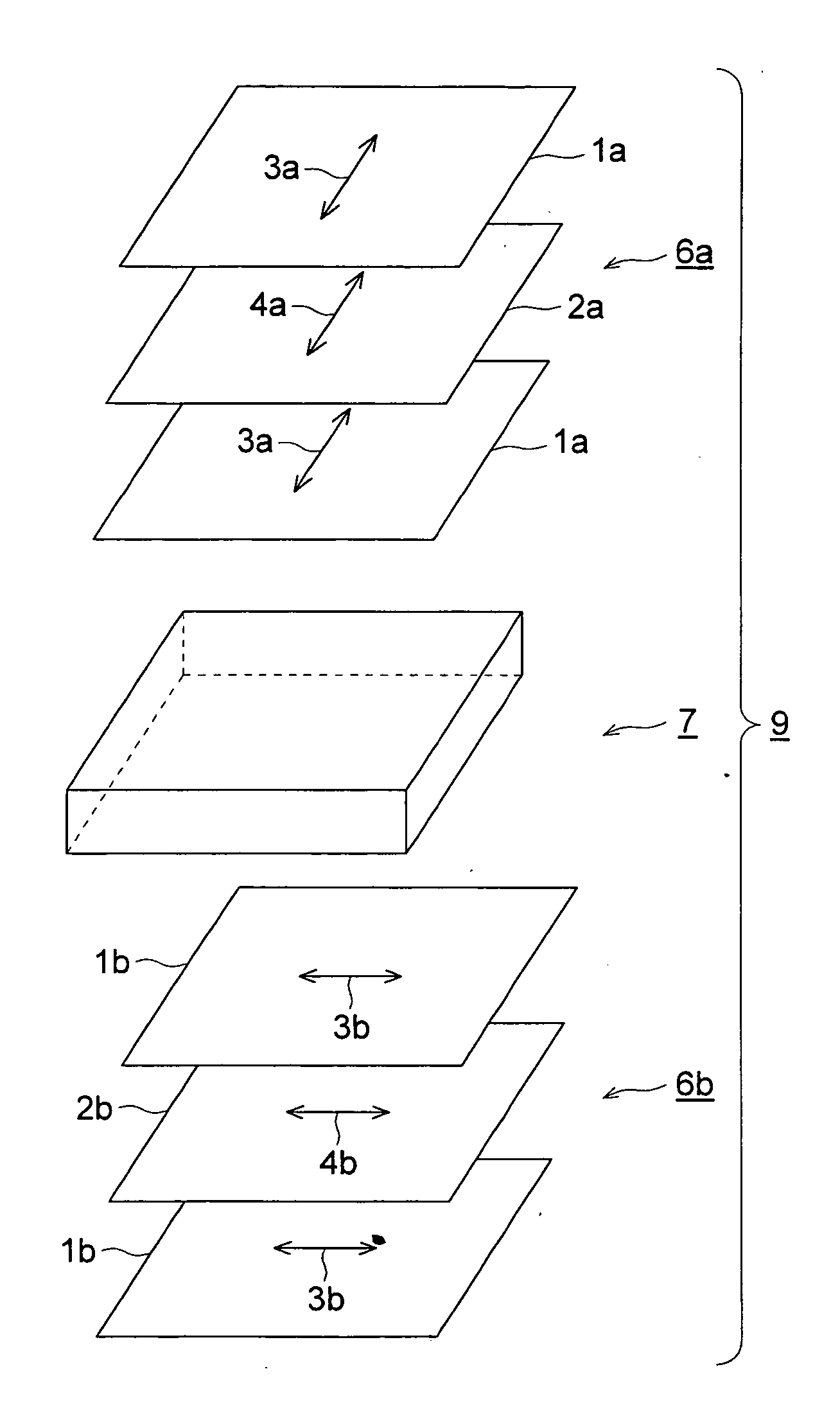

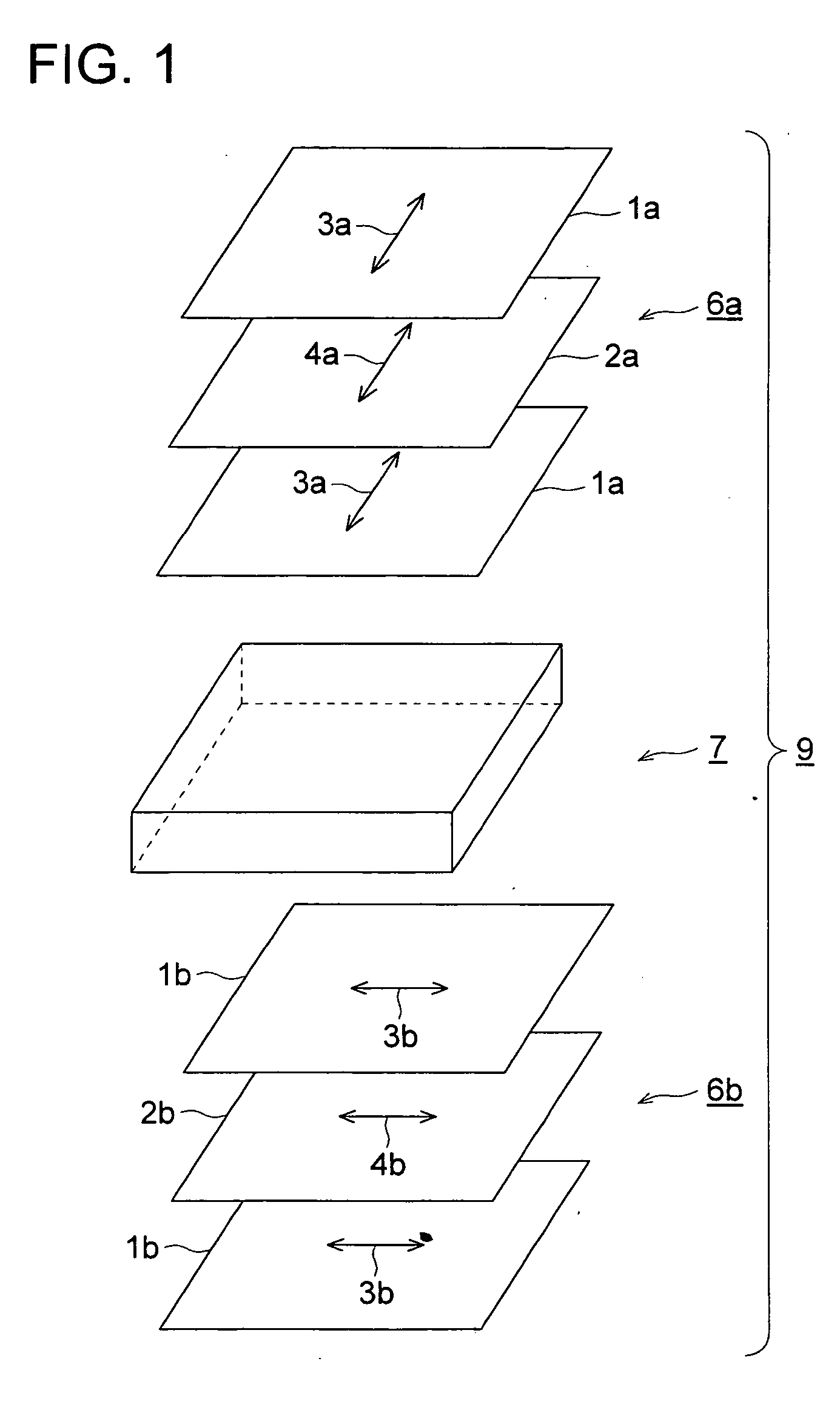

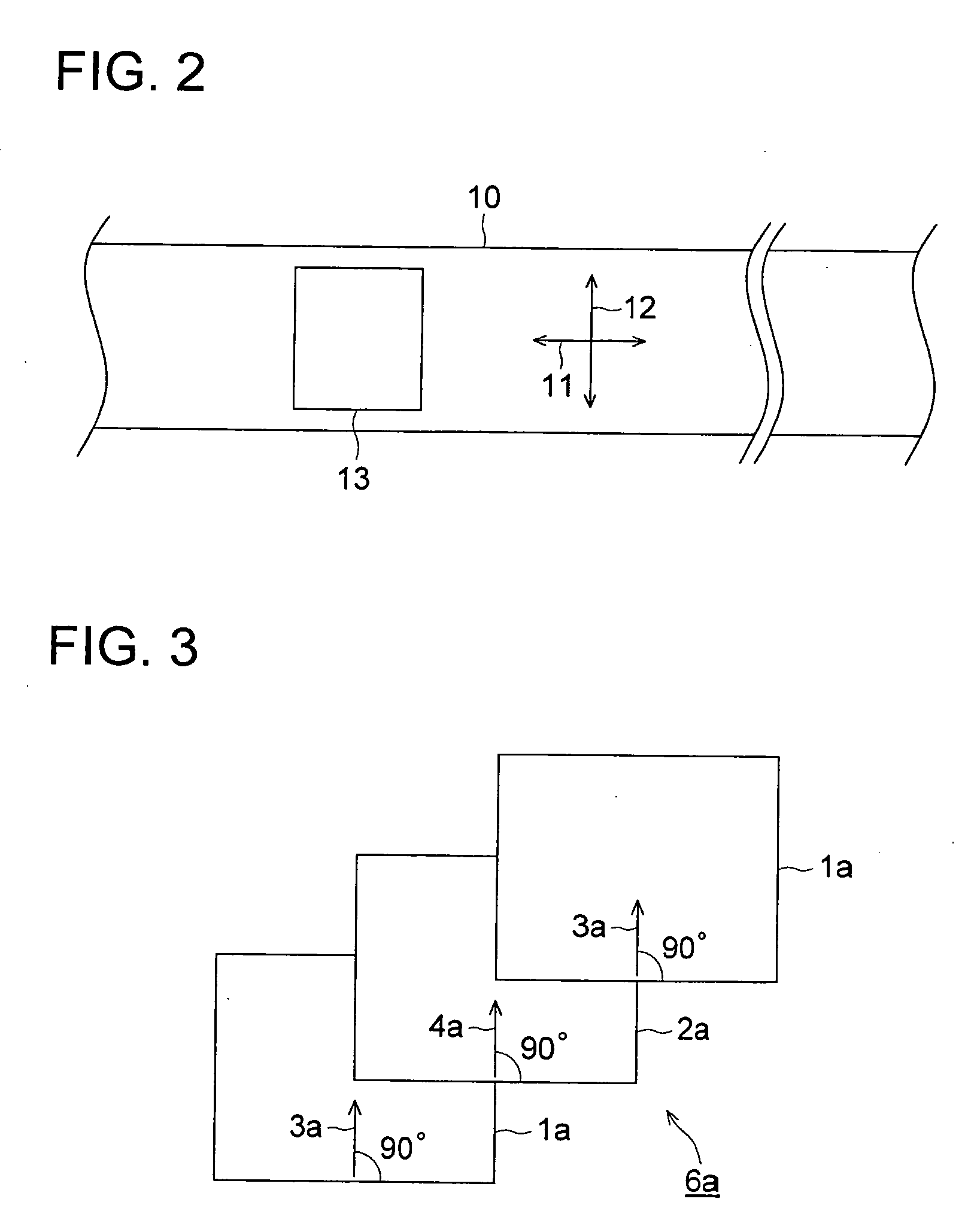

Method used

Image

Examples

example 1

>

(Preparation of Cellulose Ester Film 1)

[0189] Cellulose acetate propionate (with an acetyl substitution degree of 2.00 and a propionyl substitution degree of 0.80 and a viscosity average polymerization degree of 350) of 100 parts by weight, 5 parts by weight of ethylphthalylethyl glycolate, 3 parts by weight of triphenyl phosphate, 290 parts by weight of methylene chloride, and 60 parts by weight of ethanol were placed into a tightly sealed vessel, and gradually heated to 45° C. in 60 minutes while slowly stirred. Pressure in the vessel was 121 kpa. The resulting solution was filtered employing Azumi filter paper No. 244, produced by Azumi Roshi Co., Ltd., and allowed to stand for 24 hours to remove foams in the solution. Thus, a cellulose ester solution was prepared.

[0190] Five parts by weight of the cellulose acetate propionate described above, 6 parts by weight of TINUVIN 326 (produced by Ciba Specialty Co., Ltd.), 4 parts by weight of TINUVIN 109 (produced by Ciba Specialty ...

example 2

[0260] Polarizing plate samples 9 through 14 were prepared according to the following procedures:

9>>

(Preparation of Cellulose Ester Film TAC-A)

[0261] Cellulose ester film TAC-A was prepared according to the following procedures:

[0262] Cellulose triacetate (with an acetyl substitution degree of 2.92 and a viscosity average polymerization degree of 300) of 100 parts by weight, 2 parts by weight of ethylphthalylethyl glycolate, 8.5 parts by weight of triphenyl phosphate, 350 parts by weight of methylene chloride, and 50 parts by weight of ethanol were placed into a tightly sealed vessel, and gradually heated to 45° C. in 60 minutes while slowly stirred. Pressure in the vessel was 121 kPa. The resulting solution was filtered employing Azumi filter paper No. 244, produced by Azumi Roshi Co., Ltd., and allowed to stand for 24 hours to remove foams in the solution. Thus, a cellulose ester solution was prepared.

[0263] Five parts by weight of the cellulose triacetate described above, 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com