Extraction method for unsaturated fatty acid

An unsaturated fatty acid and extraction method technology, applied in the field of unsaturated fatty acid extraction, can solve the problems of poor economic benefit, high extraction cost, low yield of unsaturated fatty acid, etc., to improve efficiency, reduce production cost, and increase added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

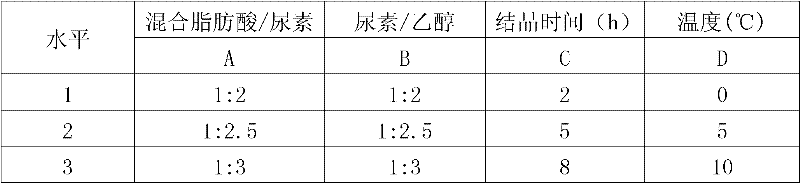

Image

Examples

Embodiment 1

[0022] Example 1: Extraction of unsaturated fatty acids from goose belly fat (addition of mixed fatty acid extraction step)

[0023] 1. Preparation of fat liver goose belly fat crude goose oil

[0024] Crude goose oil extraction: take a certain quality of fat liver and goose belly fat and cut into 1cm 3 The left and right lumps are mashed for 5 minutes with a tissue masher at 2000 revolutions / min. The mashed goose belly fat is placed in different heat-resistant containers and heated to 40℃, 50℃, 60℃ and 70℃ in a water bath. , 80℃, keep at constant temperature for 30min, stir continuously during the heating process, centrifuge at 4000r / min for 10min while it is hot, filter with three layers of gauze, and weigh to obtain crude goose oil.

[0025] The analysis of the extraction rate and fatty acid content of crude goose oil shows that the optimal extraction temperature of crude goose oil is 60°C. At this temperature, the fat liver and goose belly fat can be quickly melted, which can pre...

Embodiment 2

[0046] Example 2: Extraction of unsaturated fatty acids from goose belly fat (excluding the step of extracting mixed fatty acids)

[0047] According to the steps and conditions of Example 1, the fat liver goose belly fat was subjected to the extraction of unsaturated fatty acids, but it was directly transferred to the unsaturated fatty acid preparation step after the refining step of the crude goose oil. The results showed that the extraction rate of unsaturated fatty acids was very high. Low, the purity of unsaturated fatty acids is not significantly different from refined goose oil, and its purity is only about 60%, which is far less than the 80%-90% of Example 1. Therefore, the mixed fatty acid extraction step of the present invention has an important effect on the extraction of goose belly fat unsaturated fatty acids, can greatly improve the purity of unsaturated fatty acids, and will not cause the loss of unsaturated fatty acids.

[0048] The extraction method and the determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com