Environment-friendly oil-soluble anti-caking agent for compound fertilizer and preparation method thereof

An anti-caking agent and compound fertilizer technology, applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problems of dust pollution and large amount of dust, and achieve the effects of low cost, good anti-caking performance and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

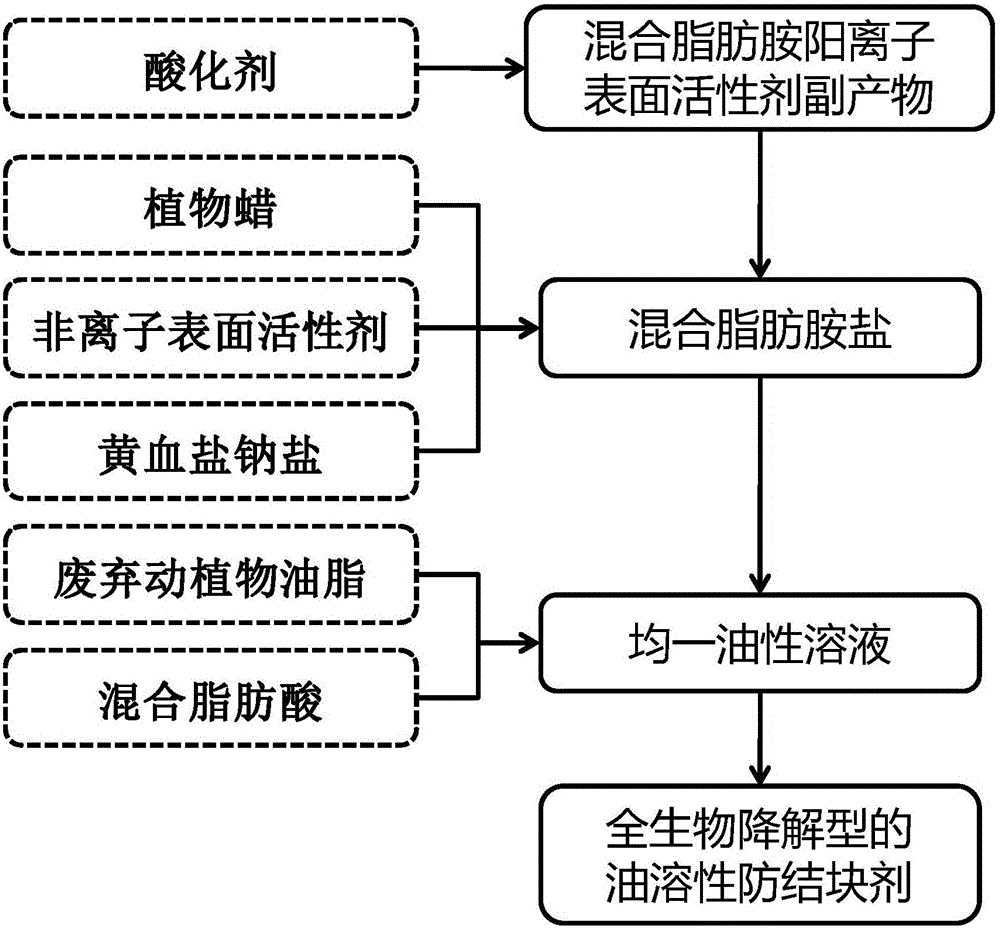

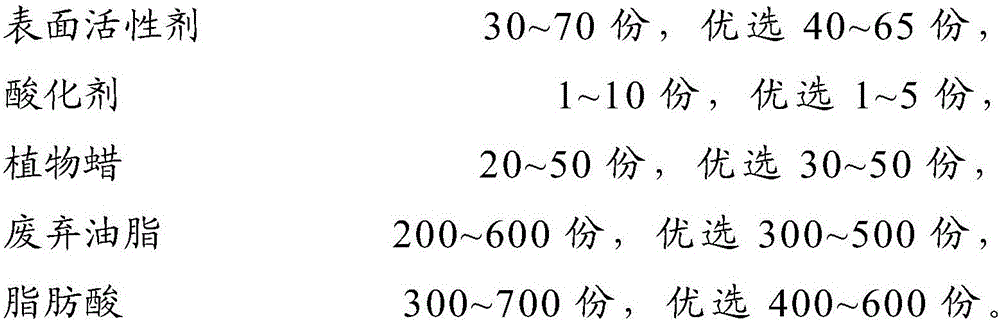

Method used

Image

Examples

Embodiment 1

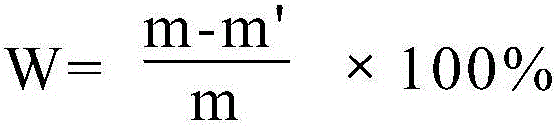

[0099] Weigh 0.44g of the pretreated aliphatic amine cationic surfactant, add 0.02g of concentrated hydrochloric acid as an acidifying agent, stir well, then add 0.34g of rice bran wax, heat, raise the temperature to 100°C, stir for 10min, to a uniform solution. Then add 12g of stearic acid and 7.2g of animal and vegetable oils, heat up to 80°C, stir for 15min, and obtain a homogeneous solution. After cooling, the sample is obtained. Embodiment 1 is tested according to the above laboratory sample performance test method, and compound fertilizer is potassium sulfate type (N: P 2 o 5 :K 2 0=15:15:15). The anti-caking performance test result of Example 1 shows that the looseness after 7 days is 96%.

Embodiment 2

[0101] Weigh 5.56g of the pretreated aliphatic amine cationic surfactant, add 0.27g of concentrated hydrochloric acid acidifier, stir evenly, then add 4.17g of rice bran wax, heat, raise the temperature to 100°C, stir for 10min, to a uniform solution. Then add 10 g of stearic acid and 8 g of animal and vegetable oils, heat up to 80° C., stir for 15 min, and obtain a uniform solution. After cooling, the sample is obtained. Embodiment 2 is tested according to the above laboratory sample performance test method, and compound fertilizer is potassium sulfate type (N: P 2 o 5 :K 2 0=15:15:15). The anti-caking performance test result of Example 2 shows that the looseness after 7 days is 97%.

Embodiment 3

[0103] Weigh 0.56kg of the pretreated aliphatic amine cationic surfactant, add 0.02kg of concentrated hydrochloric acid acidifier, stir evenly, then add 0.42kg of rice bran wax, heat, raise the temperature to 100°C, stir for 10min, to a uniform solution. Then add 18kg of stearic acid and 11kg of animal and vegetable oils, heat up to 80°C, stir for 15min, and obtain a homogeneous solution. After cooling, the sample is obtained. Embodiment 3 is tested according to the above field performance test method, and the compound fertilizer is a high nitrogen fertilizer (N:P 2 o 5 :K 2 O=28:6:6), the stacking time is 20 days. The anti-caking performance test result of Example 3 shows that the looseness after 20 days is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com