Fatty acid mixture amide propyl betaine and preparation method thereof

A technology of fatty acid amidopropyl betaine and fatty acid amidopropyl tertiary amine, which is applied in the field of mixed fatty acid amidopropyl betaine and its preparation, can solve problems affecting application and poor solubility, and achieve diverse production raw materials, reduced production costs, The effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 rapeseed oil fatty acid amidopropyl carboxyethyl betaine

[0049] This embodiment provides a kind of rapeseed oil fatty acid amidopropyl carboxyethyl betaine, which is synthesized through the following steps:

[0050] (1) Amidation reaction: Rapeseed oil and N,N-dimethyl-1,3-propanediamine are used as reaction raw materials (the ratio of substances is 1 / 3.6), and 1wt% catalyst sodium methoxide or hydrogen is added Potassium oxide, reacted at 160°C for 8 hours to obtain the intermediate of rapeseed oil fatty acid amidopropyl tertiary amine and separate the by-product glycerin;

[0051] (2) Quaternization reaction: Rapeseed oil was obtained by reacting rapeseed oil fatty acid amide and sodium chloroacetate (mass ratio: 1 / 1.05) in a mixed solvent (isopropanol / water) at 80°C for 12 hours Fatty acid amidopropyl carboxyethyl betaine.

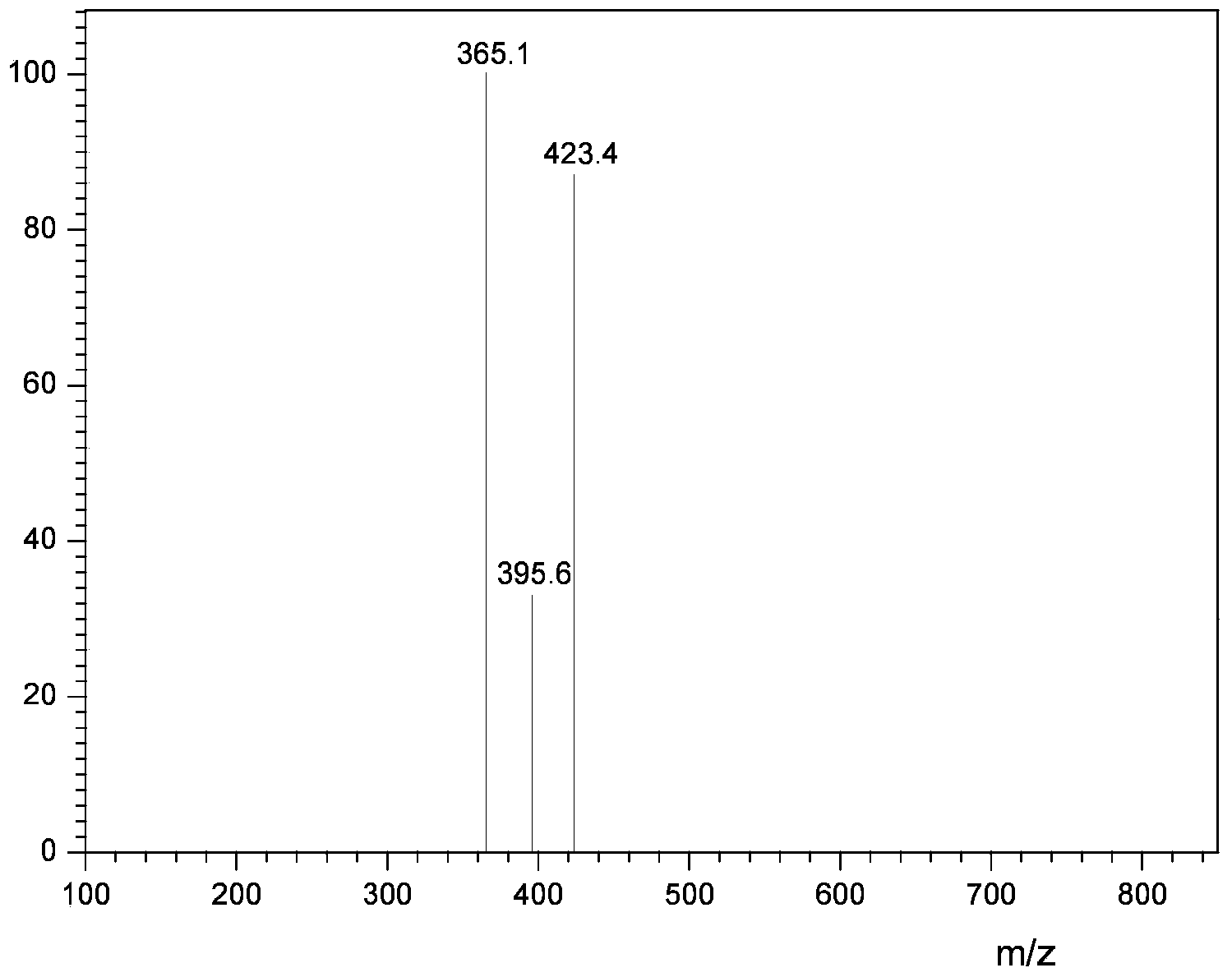

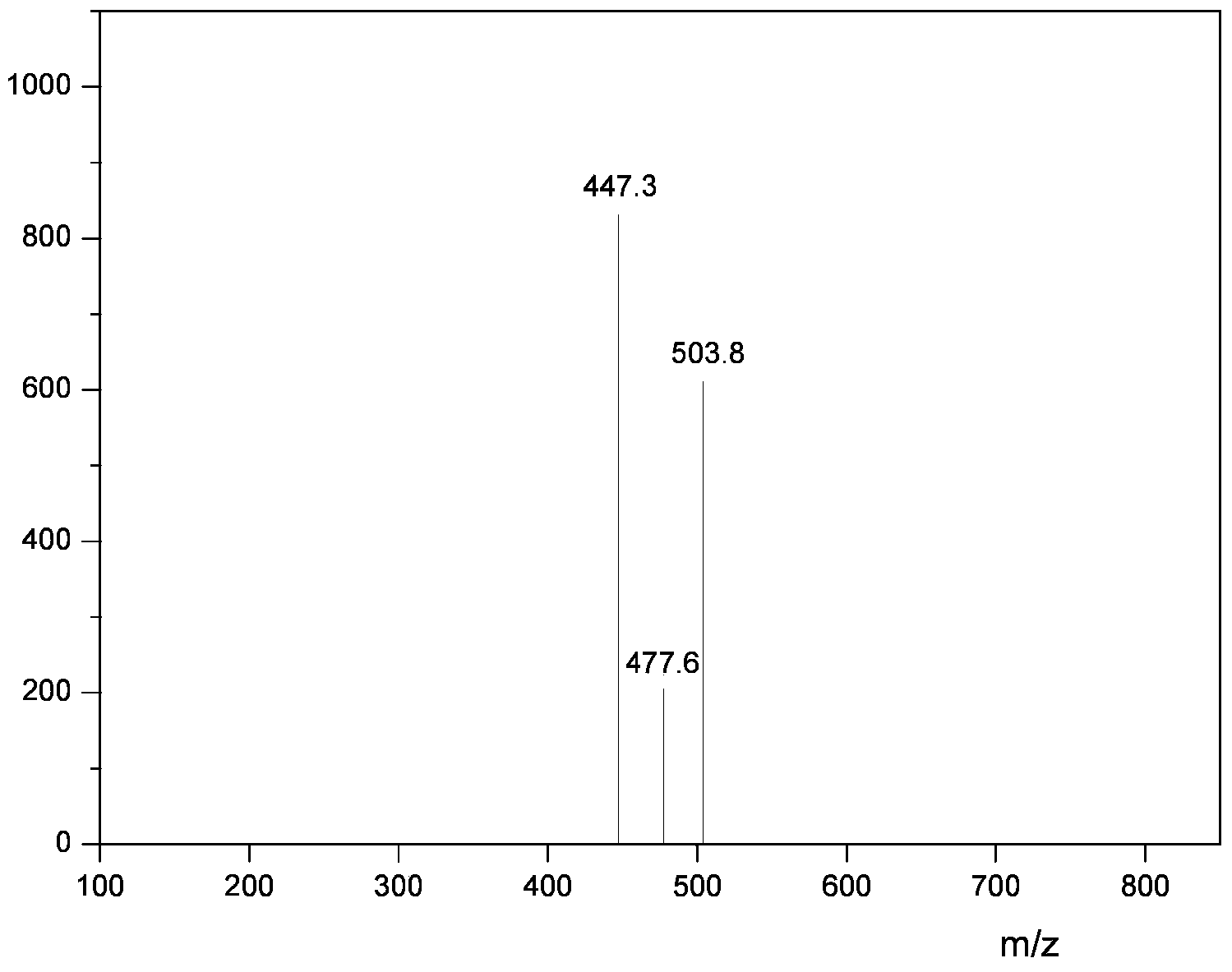

[0052] The mass spectrum of the intermediate rapeseed oil fatty acid amidopropyl tertiary amine and the product rapeseed oil fa...

Embodiment 2

[0054] Embodiment 2 rapeseed oil fatty acid amide propyl hydroxypropyl sultaine

[0055] This embodiment provides a kind of rapeseed oil fatty acid amide propyl hydroxypropyl sultaine, which is synthesized by the following steps:

[0056] (1) Amidation reaction: using rapeseed oil fatty acid and N,N-dimethyl-1,3-propanediamine as the reaction raw materials (the molar ratio of the substances is 1 / 1.2), react at 170°C for 10h to obtain vegetable Seed oil fatty acid amidopropyl tertiary amine intermediate;

[0057] (2) Quaternization reaction: Rapeseed oil fatty acid amide and sodium 3-chloro-2-hydroxypropanesulfonate (ratio of substance is 1 / 1.05) under the action of mixed solvent (isopropanol / water) at 80 ℃ for 12 hours to obtain rapeseed oil fatty acid amide hydroxypropyl sultaine.

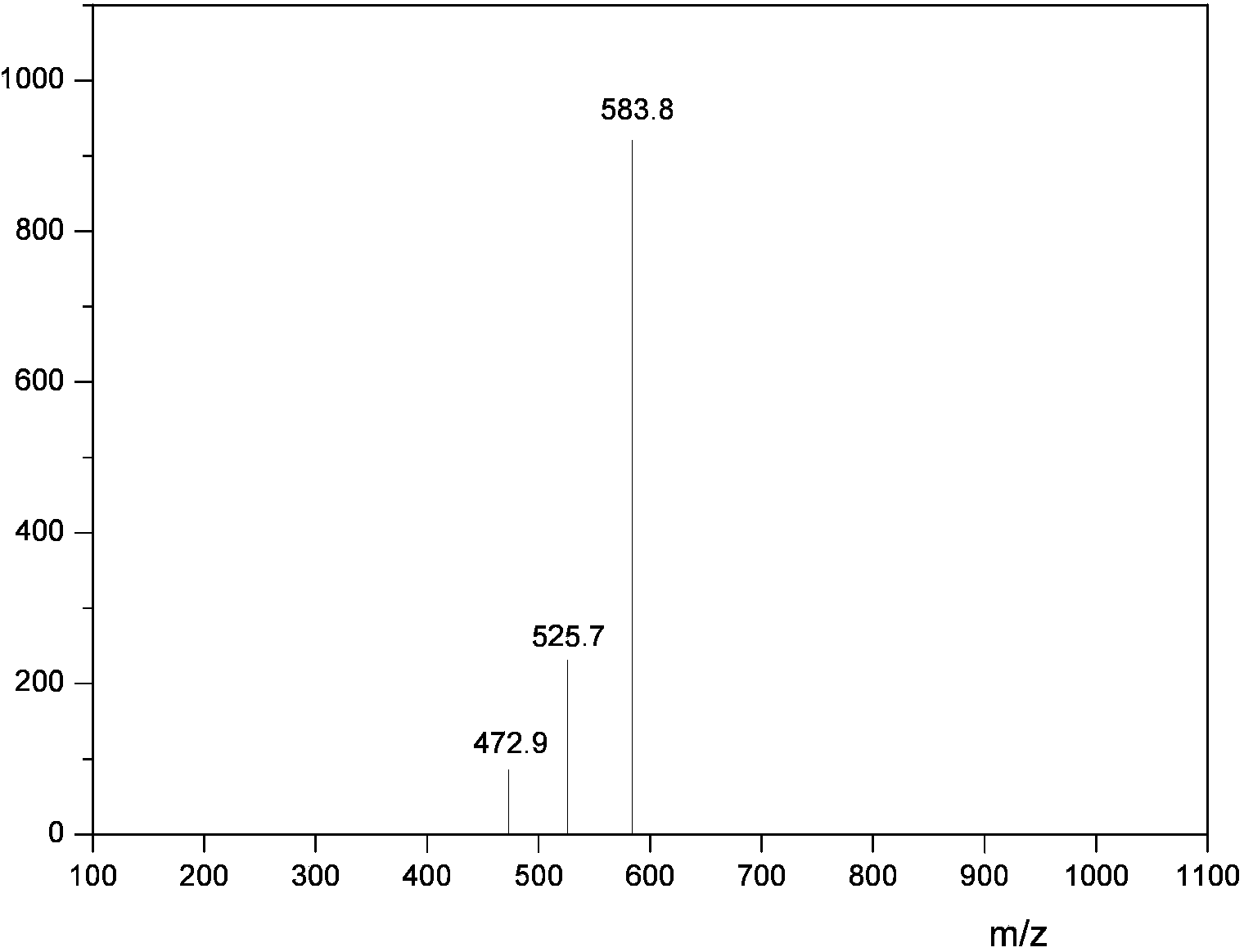

[0058] The mass spectrum of the product rapeseed oil fatty acid amidopropyl carboxypropyl sultaine is shown in image 3 .

[0059] Depend on image 3 It can be seen that oleic acid amidopropy...

Embodiment 3

[0060] Embodiment 3 soybean oil fatty acid amidopropyl ethyl sulfobetaine

[0061] This embodiment provides a kind of soybean oil fatty acid amidopropyl ethyl sulfobetaine, which is synthesized through the following steps:

[0062] (1) Amidation reaction: using soybean oil fatty acid methyl ester and N,N-dimethyl-1,3-propanediamine as reaction raw materials (mass ratio: 1 / 1.2), reacting at 155°C for 10 hours to obtain Soybean oil fatty acid amidopropyl tertiary amine intermediate;

[0063] (2) Quaternization reaction: react soybean oil fatty acid amide with sodium 2-ethanesulfonate (mass ratio: 1 / 1.05) in a mixed solvent (isopropanol / water) at 80°C for 12 hours to obtain soybean oil Fatty acid amidopropyl ethyl sultaine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com