Extraction method of japan wax, japan wax composite nano material and preparation method

A technology of inorganic nanomaterials and wild lacquer, which is applied in the recovery/refining of fatty substances and the production of fat, which can solve the problems of poor decolorization effect, difficulties in industrial production, and failure to solve the problem of filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A method for extracting wild sumac wax, comprising the following steps:

[0059] The first step, pretreatment of raw materials: remove impurities from wild sumac seeds to obtain the fleshy part of sumac seeds, and then crush them into fine powder. lower fleshy part

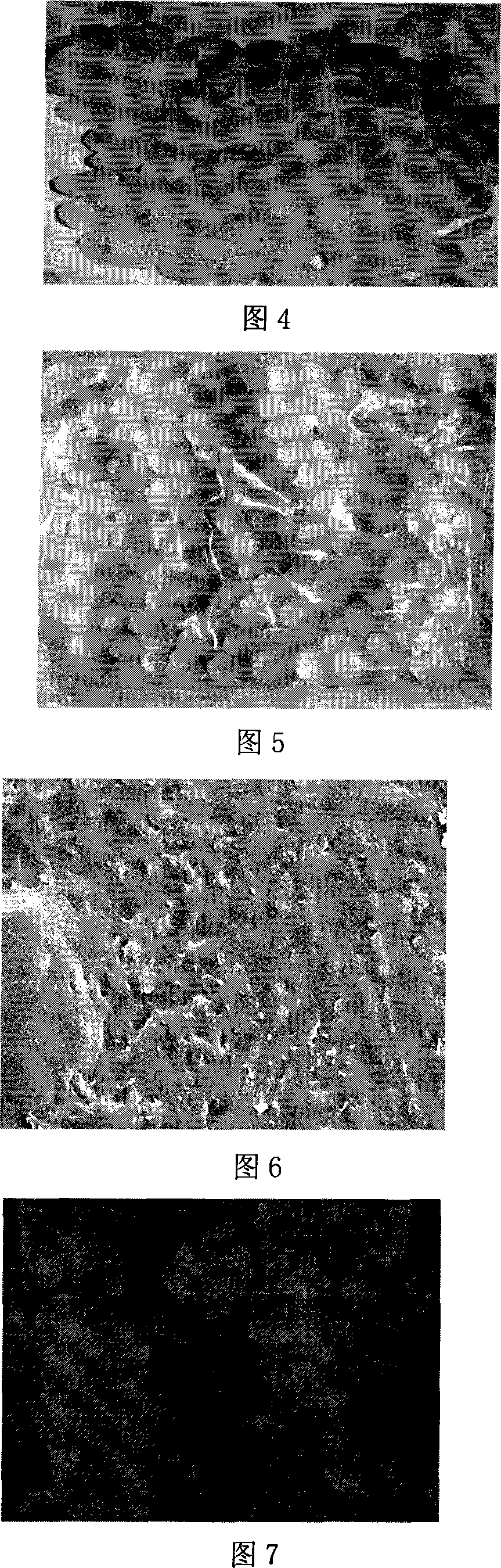

[0060]The second step, leaching: use a non-polar solvent to carry out horizontal rotation continuous leaching of the fine powder to obtain an extracting solution. The extraction temperature is 10°C-90°C. For example, the temperature can be selected as: 20°C, 30°C, 40°C, 55°C, 60°C, 65°C, 70°C, 80°C, 85°C, the feeding speed is 50g / min-2000g / min, for example, it can be selected as: 60g / min, 80g / min, 100g / min, 300g / min, 500g / min, 800g / min, 900g / min, 1100g / min, 1300g / min, 1700g / min, 1900g / min, the spray amount of non-polar solvent is 1L~30L / min, for example, it can be selected as : 1.5L / min, 3L / min, 5L / min, 6L / min, 8L / min, 12L / min, 15L / min, 17L / min, 18L / min, 20L / min, 23L / min, 24L / min, 26L / min, 28L / min, 29L / ...

Embodiment 2

[0065] The present invention also utilizes the vacuum concentrate prepared by the method of Example 1 to prepare a composite nanomaterial:

[0066] The present invention also provides a kind of wild sumac wax composite nano material, comprising described wild sumac wax vacuum concentrate and inorganic nano material, wherein, the mass ratio of inorganic nano material and described wild sumac wax vacuum concentrate is 1:( 100-1000). For example, the mass ratio can be selected as: 1:150, 1:180, 1:250, 1:300, 1:400, 1:500, 1:600, 1:700, 1:750, 1:860, 1:900 , 1:950, 1:980, the inorganic nano-material can be selected as one of nano-silicon dioxide and nano-titanium dioxide, and its particle size is less than 100nm.

Embodiment 3

[0068] A method for preparing the wild sumac wax composite nanomaterial described in Example 2, heating the described wild sumac wax vacuum concentrate to 50°C-120°C, for example, can be selected as: 60°C, 80°C, 90°C, 110°C ℃, add inorganic nanomaterials, keep stirring at the above temperature for 5-40 minutes, for example, 8 minutes, 10 minutes, 15 minutes, 30 minutes, 35 minutes can be selected. The stirring time is to form a homogeneous wax liquid, which is granulated through the nozzle of the spherical granulator The high-temperature area in the machine forms spherical droplets, which are gradually cooled in the water cooling tower, and then sprayed with water for secondary cooling, then enter the draining screen, part of the free water is removed, and white paint wax particles are obtained, and then air-dried and dehydrated by the fluidized bed , forming spherical lacquer wax particles, the spherical particle diameter of molding and granulation is 0.5-5mm, which is titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com